Market Insight

Market Insight courtesy of Argus Media

Market Insight courtesy of Argus Media

Saudi Aramco has confirmed a phased development approach for its $100 billion-plus Jafurah unconventional onshore gas project, which is expected to produce up to 2 billion cubic feet per day of gas by 2030, raising the company’s overall gas production capacity by 50% over that time frame. Aramco says that the first development phase for the Jafurah gas plant is likely to come on stream by 2025, and it is progressing with the phased development of a project that will reach a raw gas processing capacity of 3.1 bcf/d.

H.J. Baker’s chief operating officer (COO) Luis Masroua has become president of the company.

Inshan S. Mohammed of Sulfur Recovery Engineering shares lessons learned from a recent SRU shutdown assistance programme involving an error with the tags used within the BMS system installed on a direct-fired reheater.

A large portion of the oil reserves of Canada and Venezuela exist as oil sands. By the mid-2000s, production from these sources had topped 5.5 million bbl/d. But with Venezuela’s economic implosion and increasing environmental scrutiny of oil sands production, what is the future for this high sulphur fuel source?

Marco van Son and Frank Bela of Comprimo share lessons learned from SRU war stories, including: inadvertent NH3 destruction in an oxidising atmosphere, rich amine emulsion, SWS fixed valve trays, H2 spiking of SRU feed, rich amine flash drum early warning, V-ball fuel gas safety shutoff valves, TGTU methyl mercaptan, and commissioning and Murphy’s Law.

The purpose of this article is to emphasise the lessons learned by ADNOC Sour Gas in the material upgrading of the Shah sulphur granulation plant due to severe corrosion of the aluminium components. The sulphur granulation plant was commissioned in 2015 and consists of a total of 12 granulating systems used for solidifying and granulating the liquid sulphur. The study focused on the corroded areas, namely the GX plenum chambers, the lower section of the granulator exhaust stack, the scrubber inlet and the discharge ducting.

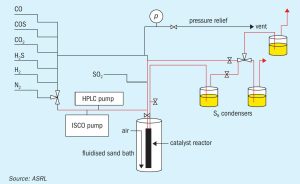

Temperature dependent rate constants for the hydrolysis of CS2 and COS across Claus Al2 O3 and TiO2 catalysts are valuable tools for the design and optimisation of new, as well as existing, sulphur recovery units. In this context, Alberta Sulphur Research Ltd (ASRL) has measured CS2 and COS hydrolysis rates over a range of temperatures for both Al2 O3 and TiO2 catalysts under start-of-run and, more recently, end-of-run first converter conditions. In this article Christopher Lavery, Dao Li, Ruohong Sui, and Robert A. Marriott of ASRL report on their methodology and the utility of the kinetics calculated from their data and draw comparisons between the start-of-run and end-of-run results.

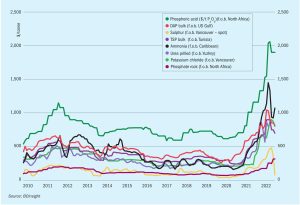

Reduced appetite for sulphur from processed phosphates producers in China will continue to place downwards pressure on pricing in the near term. l Phosphates-based demand is likely to remain low in the second half of 2022 as issues surrounding affordability persist, slowing import requirements.

The US refining sector continues to face operating pressures with 1.3 million bbl/d of closures in the past three years, while sour gas sulphur production has recovered somewhat. Meanwhile, demand from copper and lithium leaching projects will increase use of sulphuric acid over the next few years.