MEScon returns to Abu Dhabi

CRU and UniverSUL Consulting, together with the event host, ADNOC, are delighted to welcome you back for MEScon 2024 at the Conrad Abu Dhabi, Etihad Towers from 20 to 23 May 2024.

CRU and UniverSUL Consulting, together with the event host, ADNOC, are delighted to welcome you back for MEScon 2024 at the Conrad Abu Dhabi, Etihad Towers from 20 to 23 May 2024.

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.

ASRL discusses why sulphur tends to be friable and explores several measurements cited in many specification documents, with the purpose of focusing on several modern solid forms. In addition, the measurement of total and extraneous water is explored.

Sulphur production continues to expand in the Middle East and China both from new refineries and major sour gas projects.

It is generally necessary to solidify sulphur into a robust form suitable for handling and long-distance transport. Granulation, pastillation and prilling are some of the technologies used to produce solid sulphur from molten material. Similar technologies are also used to manufacture sulphur fertilizers.

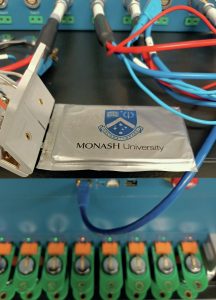

Researchers from Australia’s Monash University say that they have created a new generation of lithium-sulphur batteries which could provide a cheaper, cleaner and faster-charging energy storage solution that outlasts lithium-ion alternatives and is rechargeable hundreds of times without failing. The team has creating a new interlayer which allows for exceptionally fast lithium transfer, as well as an improvement in the performance and lifetime of the batteries.

Dealing with sulphur dust is an operational challenge for sulphur forming plants and sulphur storage and handling facilities.

Sulphur processing and handling equipment manufacturer IPCO has completed the commissioning of a groundbreaking new drum granulator in Italy that will serve as a global showcase for this patented system. C. Metheral of IPCO, describes the innovative approach and key features of the SG20 sulphur granulation system.

Sulphur ’s annual listing of new or recently completed sulphur forming projects worldwide covers both new sour gas and refinery sulphur forming projects as well as upgrades at existing units.

For the protection of nozzles in sulphur forming plants it is important to prevent larger particles from entering the forming machinery and possibly blocking the nozzles. In normal operation, pipeline strainers are used. Sulphurnet has designed a new system which is suitable for continuous or batch operations and has lower maintenance costs. J. Hermans of Sulphurnet introduces the self-cleaning sulphur strainer.