Sulphur plant revamps to meet future challenges

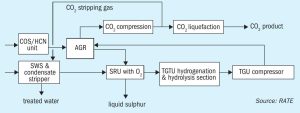

RATE USA discusess some of the many solutions available to revamp sulphur plants to meet stricter environmental regulations with regard to SO2 and CO2 emissions.

RATE USA discusess some of the many solutions available to revamp sulphur plants to meet stricter environmental regulations with regard to SO2 and CO2 emissions.

In spite of changing patterns of demand, deglobalisation and environmental concerns, phosphate mining and acid-based processing are likely to be the mainstay of the industry for years to come.

Low carbon production is attracting considerable attention to using syngas derivatives as fuels, but there are considerable logistical and commercial barriers to overcome.

Market Insight courtesy of Argus Media

CF Fertilisers UK Limited, a subsidiary of CF Industries, says that it plans to permanently close the ammonia plant at its Billingham fertilizer complex in order to secure the long-term sustainability of its business in the UK. The Company intends to continue to produce ammonium nitrate (AN) fertiliser and nitric acid at the Billingham site using imported ammonia, as it has for the last 10 months following its decision to temporarily idle the plant in August 2022.

The CO2 emissions in a hydrocarbon fed hydrogen plant occur largely during the energy intensive syngas production step. Hydrogen production is therefore a major factor in the CO2 emission balance of an ammonia plant. BASF’s OASE® technologies for CO2 capture are capable of achieving cost-effective 99.99% carbon capture at scale. In this article Elena Petriaeva and Bernhard Geis of BASF investigate different grey and blue hydrogen production technologies.

Plant digitalisation can contribute to increase the profitability of chemical plants by optimising performance of operation as well as maintenance. Available digital products range from visualisation of plant data for increased transparency to closed-loop AI controllers based on digital twins.

Prior to the covid pandemic, sub-Saharan Africa had been the fastest growing market for new fertilizer demand. However, the combination of pandemic related disruption, followed by the dislocations caused by the war in Ukraine, have pushed up prices and led to falling demand across the continent.

Venkat Pattabathula , a member of the AIChE Ammonia Safety Committee, reports on the American Institute of Chemical Engineers’ Safety in Ammonia Plants and Related Facilities Symposium, held in Munich, Germany, from 20-24 August 2023.

Lithium ion battery production is driving major expansions in nickel and cobalt extraction, but lithium iron phosphate (LFP) battery use is growing rapidly.