Making fertilizer plants safe

We look at safety, health and environmental (SHE) management and hazards at nitrogen fertilizer plants and the importance of the International Fertilizer Association’s ‘Protect & Sustain’ certification scheme.

We look at safety, health and environmental (SHE) management and hazards at nitrogen fertilizer plants and the importance of the International Fertilizer Association’s ‘Protect & Sustain’ certification scheme.

We look at state-of-the-art technology used in phosphate and potash mining, including equipment and systems for excavation, tailings thickening, transport, tunnelling and processing.

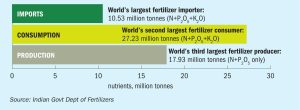

India consumed just under 57 million tonnes of fertilizers in 2018/19, cementing its position as the world’s second largest fertilizer marketplace. MP Sukumaran Nair provides an update on the country’s fertilizer industry, its continuing import reliance and the strong influence of government policy.

The grave economic and human health consequences of the global spread of coronavirus (Covid-19) deepened in March.

With more than 15 million hectares of land watered by drip irrigation globally, the technology’s agricultural potential remains enormous. Fertigation – the ability to manage and regulate both water and plant nutrients – is a key advantage helping drive worldwide growth.

Rice is one of the world’s most popular food staples, providing around one-fifth of the total global calorific value of human diets. Cultivation and consumption is particularly prevalent in Asian countries. We look at the nutrient needs of this widely-grown cereal.

A New Year is typically a time for taking stock, for looking back at the year just gone, and thinking about the year to come. This year of course marks a bigger transition, from the 2010s to the 2020s. The past decade has been a volatile one, existing under the shadow of the global financial crisis of 2008-09, from which the world was still just emerging in 2010. Over the past decade, ‘quantitative easing’ has helped prevent deflation and driven a decade long stock market rally, but also kept both public and private debt levels high, as interest rates stay low. Weaning the global economy off QE has proved to be far more difficult than many anticipated.

The Sixth Annual MESPON Forum took place 7-10 October at the Rosewood Hotel Abu Dhabi, where the global sour gas and sulphur community gathered for four days of networking, learning, and collaboration. This year’s theme highlighted new trends, innovations and best practices in the field of sour gas processing that enhance operations.

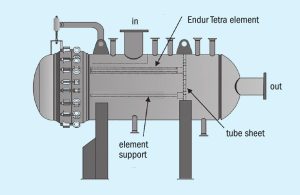

Hydrocarbon contamination of sour water streams feeding sour water strippers is a well-known challenge in the refining and gas processing industry. The source of this challenge is the formation of a stable oil emulsion in an aqueous phase that may contain both H 2 S and NH 3 . The typical approach to the problem involves large residence time tanks with the assumption that droplet settling will occur over a long enough time frame. In practice, droplet settling is very slow due to a variety of reasons, and as a result, operators encounter sour water heat exchanger fouling, stripper fouling, hydrocarbon excursions to sulphur recovery units along with other operating challenges. M. Thundyil, D. Seeger and E. McIntosh of Transcend Solutions present a case study of the TORSEP™ oil and solids removal system for contamination removal from a sour water feed stream. The case study illustrates the effect on heat exchanger fouling along with the effect of the variation of several system parameters on operating performance and economics.

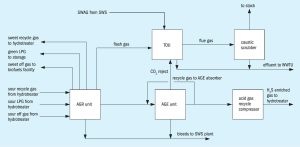

M. van Son and S. Sreejit of Comprimo present a case study involving the design and potential integration of the sour water and acid gas treatment units for a renewable diesel facility with an existing refinery sulphur complex. The case study evaluates the potential for operating cost reduction by integrating an enrichment loop in the acid gas treatment plant as well as for using the existing infrastructure of the refinery to limit emissions.