Boosting UAN efficiency with inhibitors

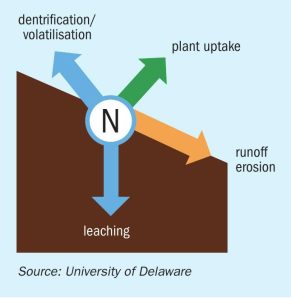

Urease and nitrification inhibitors are cost efficient and easy to implement solutions for improving the nitrogen use efficiency (NUE) of urea ammonium nitrate (UAN). The use of inhibitors enables farmers to substantially reduce nitrogen losses and achieve their environmental targets, explains Thomas Profitt , Syensqo’s Global Enhanced Efficiency Fertilizer Manager, while improving crop yields and generating a positive return on investment.