Australia’s nitrogen industry

An ammonium nitrate industry geared around producing explosives for the mining sector is now being joined by a major urea project and a number of renewables-based products for export of green ammonia.

An ammonium nitrate industry geared around producing explosives for the mining sector is now being joined by a major urea project and a number of renewables-based products for export of green ammonia.

QatarEnergy has announced its decision to build a new, world-scale urea production complex that will more than double Qatar’s urea production. The project is aiming to construct three ammonia production lines which will supply four new world-scale urea production trains in Mesaieed Industrial City. Total capacity for the new complex is projected to be 6.4 million t/a, more than doubling Qatar’s annual urea production from about 6 million tons per annum currently to 12.4 million tons per annum. Production from the project’s first new urea train is expected before the end of this decade.

Venkat Pattabathula, a member of the AIChE Ammonia Safety Committee, reports on the American Institute of Chemical Engineers’ (AIChE) Safety in Ammonia Plants and Related Facilities Symposium held in San Diego on 8-12 September 2024.

OCI Global says that it has reached an agreement for the sale of 100% of its equity interests in its Clean Ammonia project currently under construction in Beaumont, Texas for $2.35 billion on a cash and debt free basis. The buyer is Australian LNG and energy company Woodside Energy Group Ltd. Woodside will pay 80% of the purchase price to OCI at closing of the transaction, with the balance payable at project completion, according to agreed terms and conditions. OCI will continue to manage the construction, commissioning and startup of the facility and will continue to direct the contractors until the project is fully staffed and operational, at which point it will hand it over to Woodside. The transaction is expected to close in H2 2024, subject to shareholder approval.

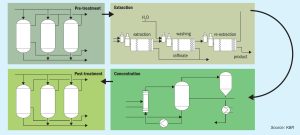

KBR designs and builds customised phosphoric acid purification plants tailored to the individual demands of clients. Christopher Heikkilä, KBR’s Business Development Manager, outlines the process design requirements and the challenges associated with impurities removal.

Large-scale ammonia cracking technology and catalysts will enable the full potential of ammonia to be realised as industries transition towards low carbon energy. In this feature we report on the current status of ammonia cracking processes and catalysts.

The board of Petrobras has approved the resumption of operations at the company’s Araucária Nitrogenados SA (ANSA) site at Araucaria, Parana state. The plant, which has the capacity to produce 475,000 t/a of ammonia and 720,000 t/a of urea, has been idled 2020.

A summary of papers presented at CRU’s Nitrogen+Syngas conference, this year held at the Gothia Towers in Gothenburg, Sweden.

The US is experiencing a new boom in nitrogen projects, with a number of carbon capture ammonia plants under development.

New blue production schemes are available to meet the need to significantly reduce the overall carbon intensity of high-volume hydrogen and ammonia production for a large-scale emerging market. KBR, Air Liquide, Mitsubishi Heavy Industries, Casale and Johnson Matthey report on their latest technologies.