Clean ammonia projects and technologies

New methods for low-carbon ammonia production are emerging, while project activity is also rising rapidly.

New methods for low-carbon ammonia production are emerging, while project activity is also rising rapidly.

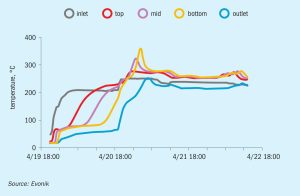

Evonik explores the development of catalyst reuse and how recycled hydroprocessing catalysts can be successfully applied in tail gas treating units to deliver cost and performance gains.

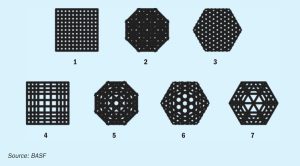

BASF is challenging traditional catalyst shapes and performance relationships using 3D-printing technology and is using sulphuric acid catalysts as the pilot to pioneer new ground.

Arafura Rare Earths Ltd has awarded Worley subsidiary Chemetics Inc the contract to install Chemetics CORE-SO2™ sulphuric acid technology at its Nolans Project in the Northern Territory of Australia. The scope of the contract is to deliver the detailed engineering and supply of the sulphuric acid plant plus associated oxygen plant on a lump sum basis. The acid plant at Arafura’s Nolans Project will be designed to meet future emission performance and clean energy transition goals, utilising CORE-SO2’s high turndown capability and the potential to idle the plant while keeping the catalyst warm for extended periods of time, allowing the acid plant to operate with 95% reduced SO 2 emissions when compared to traditional double contact double absorption (DCDA) plants. High pressure steam production within the process will allow CO 2 - free electrical power to be generated. By removing the use of a diesel or natural gas start-up burner, further greenhouse gas emissions will be prevented.

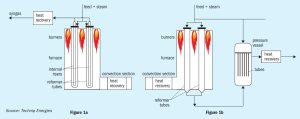

Previously, recuperative reforming has been mostly applied for capacity increase revamps, but nowadays it is a key enabler for efficient low carbon hydrogen and syngas production. Jan-Jaap Riegman of Technip Energies, Francesco Baratto of Casale and Stefan Gebert of Clariant discuss the benefits of recuperative reforming for reducing the carbon footprint of existing assets.

The steam methane reformer is at the heart of most world-scale synthesis gas plants for ammonia, methanol or hydrogen production, and its optimum performance will maximise plant production and efficiency. This article studies the wide variety of parameters that need to be considered if a steam methane reformer is optimised.

Cansu Doganay of Lux Research takes a look at the current technology landscape for methane pyrolysis for producing low-carbon hydrogen from natural gas.

Air Liquide presents the results of an internal study to identify preferred natural gas-based plant configurations at a methanol capacity of 250 t/d. Delivering small capacity plants requires a focus on the total cost of ownership (TCO) for the economics to be successful, in addition to the CO 2 footprint of the operation. As found by this study, SMR concepts are naturally power balanced for standalone greenfield operations and show no particular advantage for power import in a brownfield setting. POX and ATR cases are greatly improved and even advantaged in a brownfield setting compared to SMR when shifting from power balance to power import cases.

Advanced Methanol Amsterdam (AMA) is a production facility, that will be realised in the Port of Amsterdam's Biopark, which is destined to produce advanced methanol that meets the European renewable energy directive (RED) requirements. Once completed, AMA will be the flagship production site for GIDynamics and GIDARA Energy and for its High Temperature Winkler (HTW ® ) gasification technology. AMA will also be the first of its kind green methanol unit designed by Casale.

NORAM has recently introduced a patented acid entrainment mitigation device (EMD) to deal with acid mist carryover from sulphuric acid towers.