Nitrogen + Syngas 2022

CRU’s Nitrogen + Syngas conference returned to a face to face meeting for the first time in two years at the end of March this year.

CRU’s Nitrogen + Syngas conference returned to a face to face meeting for the first time in two years at the end of March this year.

For some years the fastest growing sector of the methanol market was Chinese olefins production. However, with growth there flattening out, it is traditional chemical uses which are taking over again as drivers of demand growth, with, longer term, a major prospect from fuel and energy applications.

Ammonia synthesis catalysts have seen major improvements over the last 100 years, and they are highly optimised with respect to activity, thermal stability, and poisoning resistance. Improving such catalysts even further requires a deep understanding of their structure and the impact of different parameters on performance. Clariant, Johnson Matthey and Topsoe report on their studies and developments in ammonia synthesis catalysts.

Late February saw the diplomatic crisis between Russia and Ukraine abruptly devolve into all-out war, on a scale not seen in Europe since the collapse of Yugoslavia in the early 1990s – some would argue not since the end of the Second World War. At time of writing, the conflict is still barely two weeks old, but has already produced an unfolding humanitarian catastrophe, and a refugee crisis of massive proportions. But over the medium and longer term, together with the international sanctions that have swiftly followed, it also has the power to deliver an economic shock to commodities markets in particular and the world economy in general that may be as bad if not worse than the crash of 2008-9.

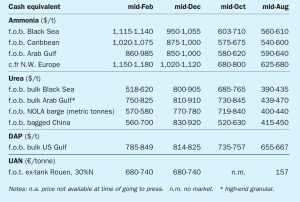

The ammonia market, already seeing record pricing in the wake of the winter’s gas price squeeze, is braced for even higher pricing in the wake of the Russian invasion of Ukraine. The impact upon gas prices has been most marked, with rates of over $65/MMBtu seen in European forward pricing as the threat of a cessation of Russian gas exports loomed. This will undoubtedly lead to widespread idling of ammonia capacity in Europe.

Market Insight courtesy of Argus Media

Switzerland-based EuroChem Group AG says it has entered into exclusive negotiations to acquire the nitrogen business of the Borealis group, after having submitted a binding offer. One of Europe’s leading fertilizer producers, Borealis operates fertilizer plants in Germany, Austria and France, as well as more than 50 distribution points across Europe. It supplies 3.9 million tonnes of fertilizer products per year, including 800,000 t/a of technical nitrogen solutions and 150,000 t/a of melamine via the Borealis LAT distribution network. It is a market leader in melamine, with its operations in Austria and Germany supplying primarily the woodworking industry. EuroChem says that melamine and technical nitrogen solutions represent important new business lines for the company to expand its nitrogen-based product portfolio in Europe.

The CRU Nitrogen + Syngas Conference returns to Berlin for a live event from 28-30 March 2022. The conference will be run as a hybrid event giving participants the option to attend live in-person or online via the virtual platform.

High feedstock prices and regulatory burdens continue to put pressure on European nitrogen producers to innovate.

New innovations, services and latest technologies to improve the operation and reliability of steam methane reformers from AMETEK Land, Kontrolltechnik, BD Energy Systems, Koch Engineered Solutions, and Quest integrity.