Sulphur + Sulphuric Acid 2025

CRU’s annual Sulphur+Sulphuric Acid Expoconference was held from November 3rd to 5th, at The Woodlands, Texas.

CRU’s annual Sulphur+Sulphuric Acid Expoconference was held from November 3rd to 5th, at The Woodlands, Texas.

A complete listing of all articles and news items that appeared in Sulphur magazine during 2025.

Sulphur prices have risen rapidly in recent months as the market moves into a period of deficit which is likely to last until 2028.

The Chinese ammonium sulphate industry continues to see rapid growth, with exports rising to record levels, against increasing demand coming from Brazil and India.

The switch towards battery technologies like lithium iron phosphate (LFP) is leading to major growth in demand for sulphur and sulphuric acid.

Süd-Chemie discusses the importance of pressure drop in a sulphuric acid plant and the many benefits that can be gained from using a guard bed, typically in the first bed of the converter to safeguard the catalyst bed and increase campaign life.

Thiomaterials reports on the key features and successful performance of Thiotrack sulphur concrete sleepers, offering high fatigue endurance with a truly reversible circular binder.

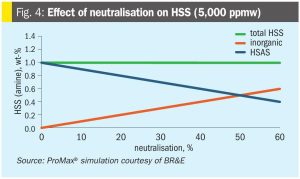

Bryan Research & Engineering (BR&E) and INEOS GAS/SPEC continue their review of neutralisation of heat stable salts. Part 2 focuses on how caustic (NaOH) affects amine chemistry and corrosion and the effects of adding too much NaOH.

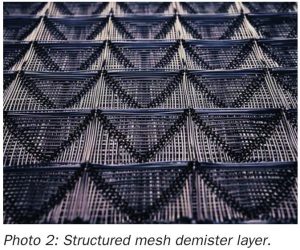

Begg Cousland Envirotec reviews different mist eliminator types and some of the operational problems encountered which can be managed by correct installation, targeted cleaning or replacement, and selecting appropriate corrosion-resistant materials.

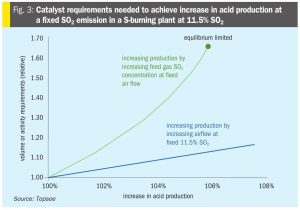

In this real world case study, Topsoe demonstrates how cost effective catalyst changes can result in significant production increase without any equipment changes or revamps, all while maintaining compliance with emission limits.