Nitrogen+Syngas 2025 Expoconference

The 38th Nitrogen+Syngas Expoconference will take place in Barcelona, Spain, from 10-12 February 2025. Join us at this industry leading event featuring the most comprehensive agenda to date.

The 38th Nitrogen+Syngas Expoconference will take place in Barcelona, Spain, from 10-12 February 2025. Join us at this industry leading event featuring the most comprehensive agenda to date.

Expensive feedstock, overseas competition and tightening environmental regulations all pose potential threats to Europe’s nitrogen industry.

A complete list of all articles and news items appearing in Nitrogen+Syngas magazine during 2024.

While there is still a considerable push for use of biomass waste as a lower carbon feedstock for chemical production via gasification to syngas, biological processes such as fermentation are increasingly gaining traction as an alternative.

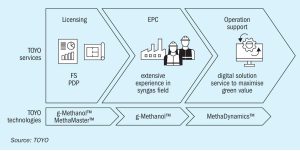

Toyo Engineering Corporation has developed two new digital solutions, MethaMaster™ and MethaDynamics™ , which enhance the operational efficiency of e-methanol production from variable renewable energy.

The production of urea, a critical component in the fertilizer industry, involves highly corrosive environments, particularly in the high-pressure sections of the process. This necessitates the use of advanced materials that can withstand such aggressive conditions to ensure long life and efficiency of urea production plants. Alleima, Stamicarbon, Saipem and TOYO report on their advanced material and equipment solutions for the urea industry.

CRU’s 38th Nitrogen+Syngas Expoconference will be held on 10-12 February 2025 in Barcelona. The most respected technical event for the global nitrogen and syngas community offers an ideal platform for industry professionals to connect, do business and learn about the latest innovations in operations, technology, process and equipment. The annual meeting attracts a global audience of producers, licensors and materials and equipment providers representing an unparalleled opportunity for business networking and peer-to-peer knowledge sharing.

An ammonium nitrate industry geared around producing explosives for the mining sector is now being joined by a major urea project and a number of renewables-based products for export of green ammonia.

In spite of increasing environmental concerns over the use of coal as a feedstock, it continues to provide around one quarter of the world’s ammonia. But in a world that is decarbonising, is there still a future for coal-based capacity?

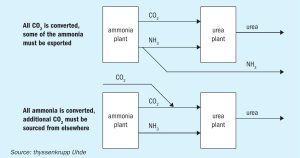

Urea revamp activities are performed to achieve improvements of the urea plant. Besides the typical capacity increase there are many options to reduce operation costs, increase plant availability or reduce environmental impact. In this article Marc Wieschalla of thyssenkrupp Uhde GmbH provides an overview of some of the options from an EPC contractor point of view.