Nitrogen project listing 2021

Nitrogen+Syngas’s annual listing of new ammonia, urea, nitric acid and ammonium nitrate plants.

Nitrogen+Syngas’s annual listing of new ammonia, urea, nitric acid and ammonium nitrate plants.

In August 2020 the tragic explosion of ammonium nitrate fertilizer in the port of Beirut caused many fatalities and injuries. This was a wake-up call for the entire industry to review the design of plants and storage facilities, as well as the procedures for plant operation and the handling of products. The key factor for safe new installations is the process design: the right choice of unit operations, operating temperatures and pressures, the control of process variables and the design of key items of equipment. A modern ammonium nitrate (AN) plant design not only mitigates the environmental impact, but also reduces investment costs and contributes to the key factors mentioned. M. Pieper and P. Kamermann of thyssenkrupp Industrial Solutions discuss how, by using the right design, safety in ammonium nitrate plants can be easily achieved, while maintaining outstanding product quality.

Gasification technology offers the promise of being able to convert the increasing volumes of municipal waste generated by society into useful chemical products. In spite of a patchy commercial record, interest in the process remains high.

By using a Rectisol™ demonstration unit at one of Air Liquide’s industrial production sites, Air Liquide Engineering & Construction has gained unique know-how in Rectisol™ column design with structured packings. S. Schmidt, R. Szabo, M. Linicus and S. Corbet report on how the application of commercially available structured packings in the absorber columns of a Rectisol™ unit results in significant capex and opex savings.

Gas availability and pricing continues to affect ammonia and methanol output from Trinidad, while Venezuela struggles with sanctions and political instability.

Although the urea market has weathered the pandemic relatively well, a significant amount of new capacity is due to come on-stream in the next year or so, and could keep prices depressed unless more Chinese capacity closes.

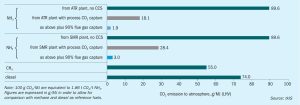

Reducing the carbon footprint in the synthesis of chemicals is a new global challenge as the world works towards providing sustainable products designed to minimise their environmental impacts throughout their whole lifecycle. This article looks at the role of blue technologies as part of a roadmap towards the decarbonisation of fuels and chemicals.

Shutdowns in technical ammonia capacity due to the pandemic have contributed to make 2020 a turbulent year for ammonia markets, but plant shutdowns, strong fertilizer demand and a shortage of new merchant ammonia capacity are contributing to finally removing the burden of overcapacity.

Ammonia synthesis catalysts have long lives and catalyst replacement is an infrequent activity. Many people will go through their careers in the ammonia industry without ever having to replace a synthesis catalyst and the infrequent nature of catalyst replacement means that many plants may not have direct experience of this activity. Ammonia synthesis catalyst can present a range of hazards throughout the replacement process, from transport through loading, reduction, start-up, shutdown and discharge, but the good practice illustrated in this article, and collaboration between catalyst suppliers and end users can ensure safe and successful catalyst changeouts.

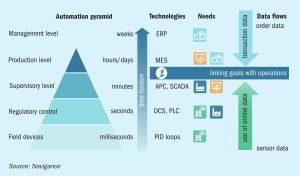

As industry trends add pressure to optimise processes, new digital technologies for roundthe-clock, data-driven decision-making can help plants boost production efficiency without time-consuming manual analysis or large-scale investment. Here, Dr S. Werner of Navigance explores their potential and shares the difference they are already making.