Sulphur content of crude feeds

US refiners have upgraded to take advantage of generally cheaper, sourer crude feeds. However, a ban on oil imports from Russia may make that harder to come by.

US refiners have upgraded to take advantage of generally cheaper, sourer crude feeds. However, a ban on oil imports from Russia may make that harder to come by.

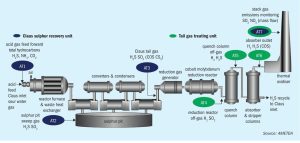

Jochen Geiger of AMETEK Process Instruments reviews SRU process analyser standards, how to choose the right instruments, what to watch out for when selecting the point of installation, responsibilities for the analysers after installation, and how to make best use of the information provided by these analysers. Potential upset conditions and how analysers can help us to understand and mitigate them are also discussed.

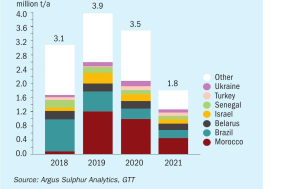

The ongoing conflict in Russia-Ukraine remains a key focus for the market in the months ahead. It is unclear whether buyers that are currently doing so will permanently choose non-Russian sulphur sources, but trade flow changes are expected to persist through the rest of 2022.

The Sulphur Community is set to reconvene in Abu Dhabi. CRU and UniverSUL Consulting, with the support of ADNOC, are hosting a new live event, Middle East Sulphur Conference (MEScon), which will take place at the Rosewood Abu Dhabi from 24-26 May 2022.

Sulphur prices keep on climbing. A quick check as I was writing this showed some indicators above $600/t, around four times what they were last year. As the title of this editorial suggests, what goes up must of course eventually come back down, but of course as always the question is: when?

The trend for multicomponent analysis of emissions from sulphur recovery units is becoming more widespread. David Inward of Sick reports on a recent field trial to test the suitability of a hot extractive infra-red analyser for this application. In addition to reliably measuring and reporting emissions to air, the analyser is also capable of contributing to reducing overall tail gas emissions by supporting enhanced optimisation of the thermal oxidiser.

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

German slurry handling specialist Vogelsang has just launched a new acidification technology which it claims will reduce ammonia emissions from agriculture, reducing up to 70% of ammonia to nutrient rich ammonium. Its new SyreN technology is an onboard sulphuric acid dosing system for tractors that treats slurry or digestate as it is applied to the land. It uses a front-linkage mounted unit to carry the acid, which also improves tractor weight distribution. The acid is dosed when the organic fertiliser is fed to the applicator, with a pH regulator automatically controlling and adjusting the flow. Nitrogen uptake of organic fertilizer is also increased by up to 1/3 as the ammonium is more easily metabolised by the soil. Results from a study in Germany showed that the acidifying slurry increased crop yield by up to 20%. The sulphur contained in the acid also becomes available to the plants as sulphate after spreading, eliminating the need for an additional pass over the field to administer a supplementary sulphur fertiliser, such as ammonium sulphate nitrate. At approximately 30 kg/ha, the amount of sulphur introduced into the crop with the SyreN system corresponds to the average amount of sulphur that is already applied to crops in the course of a growing season.

The extensive sweep of financial sanctions against Russia in the wake of the invasion of Ukraine, coupled with Russia’s position as the leading exporter of numerous commodities means that the impact of the 2022 price shock may be worse than 2008.

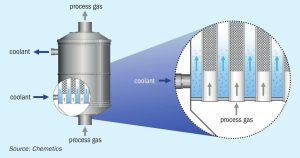

With climate change looming there is an increased focus on reducing the environmental footprint of the production of fertilizers. The use of renewable energy/green hydrogen is one way to make the fertilizer industry more environmentally sustainable. In this article, Rene Dijkstra of Chemetics introduces the Green Fertilizer Complex. This practical solution integrates an oxygen-based sulphuric acid plant using the Chemetics’ patented CORE-SO2™ process with a green hydrogen and ammonia facility to deliver low cost, low emission, and carbon-free phosphate (MAP/DAP) and/or sulphate (AMS) based ammonia fertilizers.