The merchant market for sulphuric acid

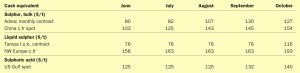

Short term supply constraints are dominating acid markets at present, but increasing smelter production across Asia may lead to oversupply in the longer term.

Short term supply constraints are dominating acid markets at present, but increasing smelter production across Asia may lead to oversupply in the longer term.

Marcus Weber of Fluor discusses degassing units for large scale sulphur recovery units, evaluating the pros and cons of various available commercial technologies with the emphasis on mega size sulphur recovery units and focussing on how technology can lower degassing capex via economy of scale for new facilities or existing facilities undergoing expansion.

Metso has appointed Sami Takaluoma the company’s new president and CEO, effective from November 1, 2024. Metso’s outgoing president and CEO, Pekka Vauramo , will continue with the company as per his contract until the end of 2024, to ensure a smooth transition of responsibilities. Sami Takaluoma has been with Metso since 1997 and has led Metso’s Services business area since 2021. He has been a member of Met-so’s Leadership Team since 2017.

Global sulphur prices underwent increases in some key benchmark markets during October, but spot activity nevertheless remained muted, with demand subdued and availability tight. Market participants continue to closely track geopolitical developments.

The development and implementation of modern process instruments and control systems in sulphur recovery units has increased significantly over the last decade. In this article, the impact of BTEX on sulphur plant operations and how the BTEX concentrations can be measured are discussed.

NextChem has been awarded two contracts to upgrade and expand the capacity of the Heydar Aliyev Oil Refinery (HAOR) industrial complex in Baku by state oil company SOCAR. As part of the contract, NextChem will conduct a technological assessment and deliver a process design package to upgrade the existing sulphur recovery unit (SRU) with oxygen enriched air, a cost-effective and flexible solution for expanding its current sulphur production capacity. Additionally, NextChem will provide the licensing and the process design package based on its proprietary NX SulphuRec TM technology for a new SRU. NX SulphuRec TM is a portfolio of proprietary sulphur recovery technologies, based on the integration of modified Claus and tail gas treatment processes, aimed at reducing the environmental impact of acid and sour gases produced during the refining process.

India’s phosphate production is using increasing volumes of sulphuric acid, but new domestic smelter and sulphur burning acid capacity may mean reduced imports in future.