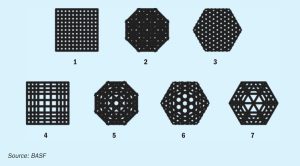

A new era in catalyst geometric shape selection

BASF is challenging traditional catalyst shapes and performance relationships using 3D-printing technology and is using sulphuric acid catalysts as the pilot to pioneer new ground.

BASF is challenging traditional catalyst shapes and performance relationships using 3D-printing technology and is using sulphuric acid catalysts as the pilot to pioneer new ground.

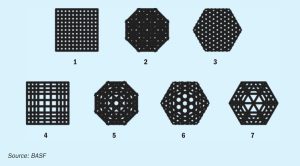

Sulfur Recovery Engineering shares the lessons learned from an emergency shutdown of an MCRC sulphur recovery unit in the middle of a cold Canadian winter.

Liquid fuels will be with us for decades to come, but refiners will be pushed to decarbonise their activities, via greater use of biofuels, and green/blue hydrogen use.

Blended and compound NPK fertilizers are a mainstay of many markets globally. We review the main production technology options.

Potash production improvements are being made in areas such as ore extraction, cooling and froth flotation. We review technological developments from Sandvik, Eriez, Nouryon and Solex Thermal Science.

Lithium sulphur batteries have many advantages over conventional lithium ion batteries in terms of energy density, and they also avoid the use of costly cobalt, but they deteriorate rapidly and cannot be recharged as frequently. However, recent advances in Li-S batteries could overcome this problem and lead to widespread adoption.

SulGas, South Asia’s sulphur recovery and gas treating conference, returned to a live event in 2023, providing participants with a platform to interact with experts in the field, share best practices and troubleshooting tips with fellow refiners and discuss advanced technologies and operating procedures with technology providers, vendors and licensors.

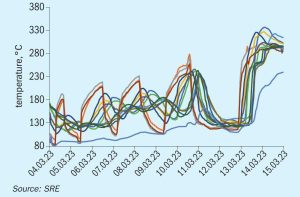

SO2 breakthroughs remain an ever present threat to the successful operation of reductive, quenchamine-based tail gas clean-up units (TGUs). Optimized Gas Treating presents a case study which demonstrates how SulphurPro's detailed reaction kinetics and mass transfer rate model can be used to analyse integration techniques and mitigation methods.

Sulphurnet discusses the importance of a whole life cycle cost analysis at the conceptual design phase when making investment decisions about new sulphur processing facilities.

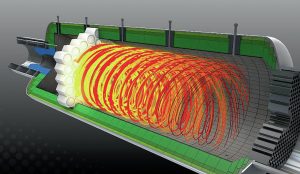

Blasch Precision Ceramics reports on the deployment of VectorWalls™ to improve the performance of the SRU thermal incinerator and provide benefits such as lower fuel gas consumption and lower CO2 emissions.