Fuel uses for syngas derivatives

Low carbon production is attracting considerable attention to using syngas derivatives as fuels, but there are considerable logistical and commercial barriers to overcome.

Low carbon production is attracting considerable attention to using syngas derivatives as fuels, but there are considerable logistical and commercial barriers to overcome.

The CO2 emissions in a hydrocarbon fed hydrogen plant occur largely during the energy intensive syngas production step. Hydrogen production is therefore a major factor in the CO2 emission balance of an ammonia plant. BASF’s OASE® technologies for CO2 capture are capable of achieving cost-effective 99.99% carbon capture at scale. In this article Elena Petriaeva and Bernhard Geis of BASF investigate different grey and blue hydrogen production technologies.

Sustainable aviation fuel (SAF) is increasingly seen as a vital tool in the aviation sector’s transition to net zero. These drop-in fuels, which can be derived from bio and renewable-derived syngas, are used to dilute the fossil-derived components of fuel and are fully compatible with existing fuel infrastructure. This positions SAF as a convenient and rapid route towards decarbonisation. However, questions remain around its ultimate viability at scale and whether it really can be the ‘silver bullet’ aviation leaders are looking for. We spoke to Paul Ticehurst from Johnson Matthey (JM) to shed some light on SAF and the future role of syngas in aviation.

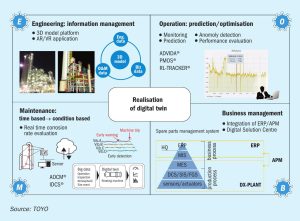

TOYO’s digital twin concept combines its unique digital twin at both the project execution stage and the commissioning stage, and when used in conjunction with its proprietary process simulator it can predict the whole plant lifecycle.

Plant digitalisation can contribute to increase the profitability of chemical plants by optimising performance of operation as well as maintenance. Available digital products range from visualisation of plant data for increased transparency to closed-loop AI controllers based on digital twins.

Venkat Pattabathula , a member of the AIChE Ammonia Safety Committee, reports on the American Institute of Chemical Engineers’ Safety in Ammonia Plants and Related Facilities Symposium, held in Munich, Germany, from 20-24 August 2023.

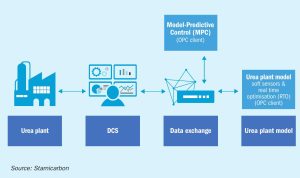

With the growing global demand for food and the rise in ecological challenges, there’s a pressing need for a more sustainable and environmentally-friendly approach to fertilizer production. Achieving a sustainable increase in plant load and operational margins through improved operations is a demanding task. Luc Dieltjens and Ali El Sibai of Stamicarbon discuss how a plant can effectively address these challenges with digital tools to optimise the process.

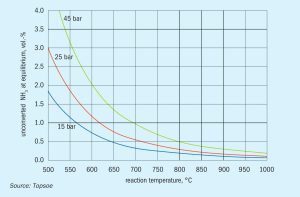

Large-scale ammonia cracking for conversion of ammonia to hydrogen is a proven technology with decades of industrial experience. Topsoe shares its experience within ammonia cracking and presents an improved and highly energy-efficient (96%) ammonia cracking technology, H2Retake™ , developed based on Topsoe’s proven technology and industrial experience.

Lithium ion battery production is driving major expansions in nickel and cobalt extraction, but lithium iron phosphate (LFP) battery use is growing rapidly.

With the aid of a rigorous kinetic model for TGU hydrogenation reactors, incorporating catalyst deactivation mechanisms, designers and operators can forecast the life expectancy of reactor catalyst beds.