Enhancing sulphuric acid production

In this case study, CS Combustion Solutions presents a comprehensive strategy for the capacity enhancement and optimisation of a sulphuric acid plant that was facing several operational challenges.

In this case study, CS Combustion Solutions presents a comprehensive strategy for the capacity enhancement and optimisation of a sulphuric acid plant that was facing several operational challenges.

This troubleshooting case study describes an incident at one of the sulphur recovery units at BPCL Kochi Refinery, India. Following a maintenance turnaround of the unit in 2022, unusually high H2 S and SO2 were observed at the outlet of the Claus section. This created an additional load on the tail gas reactor, which led to frequent plugging in the quench column and frequent outages in the tail gas unit, creating environmental and reliability issues in the unit. The activities to identify the root cause of the incident are described and the measures to solve the problem are shared.

Veolia says that its subsidiary Veolia North America has signed an agreement for the divestment of Veolia North America Regeneration Services, which includes its sulphuric acid and hydrofluoric acid regeneration activities for refineries, to private equity firm American Industrial Partners for $620 million. These activities represented revenues of around $350 million in 2023. The financial closure of the transaction is expected soon. Veolia’s Sulphuric Acid Regeneration Business includes its sulphuric acid and potassium hydroxide regeneration, as well as sulphur gas recovery, and sulphur-based products production businesses.

Optical gas imaging technology, enhanced by artificial intelligence, offers a groundbreaking approach to monitoring SO2 emissions in real time. Andrés Russu of SENSIA introduces SENSIA’s RedLook solution which offers fully autonomous, 24/7 continuous monitoring of SO2 leaks, providing industries with the tools they need to maintain environmental integrity and operational safety.

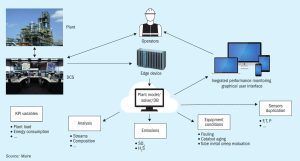

The pursuit of operational excellence requires continuous process monitoring, together with qualified analysis of the collected data. The Digital Process Monitor (DPM) provides a process digital twin which consists of an accurate process plant model that incorporates the licensor’s knowledge and expertise in sulphur recovery technology, thereby providing continuous insights into plant performance. This article provides an overview of the DPM features focusing on the related benefits in terms of overall operational improvements and plant efficiency for the sulphur recovery unit.

Representatives from across the global sulphur and sour gas community convened in Abu Dhabi from 20 to 23 May to discuss and debate the key strategic themes that are driving the industry. The Middle East Sulphur Conference (MEScon) is a premier event that brings together representatives from the entire sour gas and sulphur value chain to promote technology and innovation, lessons learned, best practices, knowledge transfer and R&D.

The refining industry continues to pivot towards Asia, with knock-on effects for sulphur output.

Liquid sulphur presents unique challenges in its handling and transport compared to solid sulphur.

As Comprimo celebrates its 100th anniversary, we explore the group’s history from its earliest days in the Netherlands in the 1920s to its current status as a global leader in gas treatment and sulphur recovery technology.

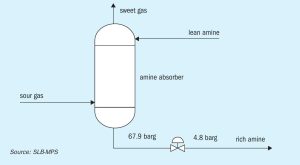

Aparna Saiju and Nishevitha U G of SLB-MPS explore the concept of energy optimisation using power recovery turbine (PRT) technology in amine sweetening units, focusing on its potential benefits, implementation strategies, and environmental implications.