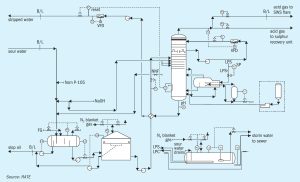

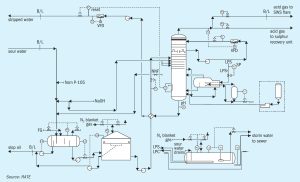

Sour water stripping gas processing options

M. Rameshni and S. Santo of RATE discuss different sour water stripping gas processing options, depending on contaminants in the sour water streams and site-specific requirements.

M. Rameshni and S. Santo of RATE discuss different sour water stripping gas processing options, depending on contaminants in the sour water streams and site-specific requirements.

Johnson Matthey’s latest methanol synthesis catalyst, KATALCO™ 51-102, was introduced in 2018 to offer improved catalyst stability and therefore higher end-of-life activity and extended lifetimes than conventional methanol synthesis catalysts. Since launch, KATALCO 51-102 has been successfully installed in two methanol plants and a third is planned for later in the year. In this article Johnson Matthey provides an update on the proven performance of KATALCO 51-102 during lab and pilot scale testing as well as in customer plants. The application of catalysts made using the KATALCO 51-102 technology for methanol synthesis via new ‘green’ routes, such as using captured and purified CO2 in conjunction with ‘green’ hydrogen, is also discussed.

MegaZonE™ is a newly introduced layered loading technology for boiling water-cooled reactors used for methanol synthesis. This new concept is one of the latest results of the long-standing collaboration between Air Liquide Engineering & Construction and Clariant Catalysts to improve the methanol process flowsheet and optimise catalyst performance in the complete reactor system.

A holistic understanding of the phosphate milling process is necessary, says Ian Hancock of Bradley Pulverizer. This ensures maximum plant uptime, the highest process efficiencies, and ultimately guarantees profitability.

To comply with stricter stack emission obligations, industries are required to recover more heat from flue gas and to clean it before it can be discharged into the atmosphere. J. Kitzhofer of APEX Group discusses the challenges and limitations of the majority of current heat recovery systems and reports on a new family of acid resistant tubular and plate-type heat exchangers developed by APEX Group that overcomes these problems. The new heat exchangers are resistant to dew point corrosion. The heat transfer elements are constructed from an acid resistant polymer composite with high thermal conductivity, allowing the design of new trouble-free heat recovery systems and the upgrade of existing systems to meet heat recovery and stack emission targets.

M. Østberg and M. Rautenbach of Haldor Topsoe describe ReShift ™ technology, a new high temperature CO 2 reforming process, where preheated CO 2 is added directly downstream of a main reformer and then equilibrated in an adiabatic reactor. This new technology makes use of the high temperature of the reformer effluent to circumvent carbon formation, while at the same time maintaining an overall minimum steam to hydrocarbon carbon ratio, depending on process specific conditions. An increase in the amount of CO 2 added to the process will result in an increased fraction of CO in the produced synthesis gas. Synthesis gas with H 2 /CO ratios in the range 0.5-3 can be produced. These CO-rich gases are typically utilised in the production of functional chemicals and synthetic fuels.

The continuing spread of alkylation technology and the preference for the sulphuric acid route are leading to increased demand for acid in refineries.

Vacuum filtration is a key process step in phosphoric acid production. We highlight the main equipment options and recent project installations.

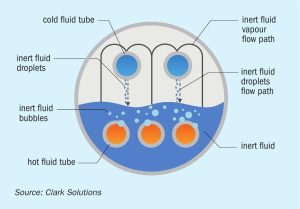

N. Clark, B. Avancini and V. Sturm of Clark Solutions discuss a novel technology, SAFEHX® , providing a new approach to the cooling of strong sulphuric acid. Prototype results are shown and indicate a safe and stable cost-effective technology. SAFEHX® can be extended to every heat exchanger system where corrosion, mixture risks, fouling, process liquid loss (or contamination) and temperature control are key concerns.

With declining ore grade feed to a metallurgical smelting process comes an increase in impurity load in the gas cleaning/acid process chain. K. Hasselwander, L. Skilling and C. Bartlett of Metso Outotec discuss a range of process solutions and how to maintain high productivity while keeping costs in check.