Nitrogen+Syngas 2025 Expoconference

The 38th Nitrogen+Syngas Expoconference will take place in Barcelona, Spain, from 10-12 February 2025. Join us at this industry leading event featuring the most comprehensive agenda to date.

The 38th Nitrogen+Syngas Expoconference will take place in Barcelona, Spain, from 10-12 February 2025. Join us at this industry leading event featuring the most comprehensive agenda to date.

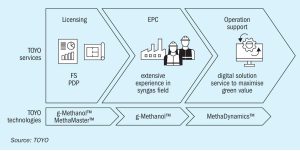

Toyo Engineering Corporation has developed two new digital solutions, MethaMaster™ and MethaDynamics™ , which enhance the operational efficiency of e-methanol production from variable renewable energy.

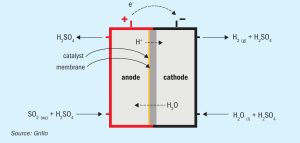

New concepts focused on the transfer and combination of existing sulphur and sulphuric acid technologies to support decarbonisation of the sulphuric acid industry are being investigated. In this article three research projects are discussed: sulphur dioxide depolarised electrolysis for green regeneration of spent acid, use of renewable heat and catalyst to the splitting process from sulphuric acid to SO2 for reduction of fossil fuel consumption, and sulphur as an energy vector.

This study introduces a new platinum-promoted honeycomb catalyst for sulphur dioxide oxidation, designed to enhance energy efficiency and reduce emissions in sulphuric acid production. Compared to conventional vanadium oxide based catalysts, the platinum-based catalyst demonstrates higher catalytic activity, lower ignition temperature, and significantly reduced toxicity.

CRU’s 38th Nitrogen+Syngas Expoconference will be held on 10-12 February 2025 in Barcelona. The most respected technical event for the global nitrogen and syngas community offers an ideal platform for industry professionals to connect, do business and learn about the latest innovations in operations, technology, process and equipment. The annual meeting attracts a global audience of producers, licensors and materials and equipment providers representing an unparalleled opportunity for business networking and peer-to-peer knowledge sharing.

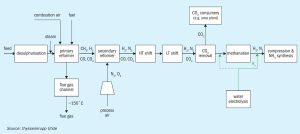

One challenge of a green revamp by stepwise injection of green hydrogen into existing ammonia/urea complexes is to cover the nitrogen demand for the ammonia synthesis while stepwise reducing the front-end load, usually by applying a cost-intensive air separation unit (ASU). thyssenkrupp Uhde GmbH has developed an advantageous concept whereby, instead of an ASU, the nitrogen gap is closed by the introduction of pretreated reformer flue gas back into the ammonia process, with the side effect to also enhance CO2 production.

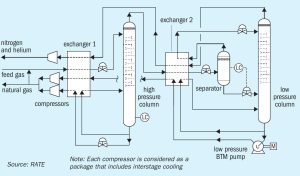

As the oil and gas industry focus on new requirements for CO2 recovery, cryogenic processes come under the spotlight. Mahin Rameshni and Stephen Santo of RATE USA discuss the importance of cryogenic processes in acid gas sweetening. Liquefied H2 S and CO2 reinjection is proposed as a cost effective alternative to large sulphur plants.

Revamping aging urea plants with the latest urea technology brings many benefits. Not only can greenhouse gas emissions be reduced, but the overall performance and sustainability of these facilities can also be optimised. Hiroo Kunii of Toyo Engineering Corporation discusses TOYO’s approach to urea plant revamping.

For six decades, Chemetics has been a pioneering force in the sulphuric acid design and equipment industry, consistently introducing groundbreaking technologies that have revolutionised the field by optimising the methodology in which chemicals are produced. This year, Chemetics celebrates its 60-year anniversary as one of the leading designers, direct equipment suppliers and fabricators that has modernised the sulphuric acid industry of today. This article dives into Chemetics’ rich history and key innovations that have shaped and moulded the industry.

QatarEnergy has announced the construction of a new world-scale ammonia-urea production complex at Mesaieed Industrial City in Qatar.