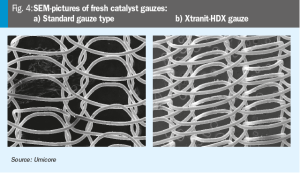

Increased efficiency through advanced gauze geometries

Umicore’s latest research and development has resulted in a novel catalyst for the Ostwald process, aiming to enhance efficiency and sustainability in high-pressure nitric acid production.

Umicore’s latest research and development has resulted in a novel catalyst for the Ostwald process, aiming to enhance efficiency and sustainability in high-pressure nitric acid production.

Dr Karl Wyant, Nutrien’s Director of Agronomy, looks at past innovations and what the future holds for phosphorus in farming.

IFA has announced the finalists of its first-ever competition to find the next generation of innovative companies.

FertigHy was founded in 2023 with the aim of developing, building and operating large-scale low-carbon fertilizer plants across Europe.

Stamicarbon is pioneering future-proof solutions for low-carbon production with two ammonia process designs.

Sulvaris is aiming to transform low-value by-products into high-performance, field-ready premium nutrient products.

MEScon 2025 took place in Abu Dhabi from 19-22 May 2025, providing delegates with renewed energy, new connections, and fresh ideas to apply across the sulphur value chain.

Granulation offers a scalable and reliable way of recovering crop nutrients from waste, says Nick Reckinger of FEECO International.

Fertiberia, OCP Nutricrops, GoudenKorrel and Omnia provide an update on the latest offerings in their product portfolios.

Dr David Marks of Levity Crop Science talks to Fertilizer International about Indra, the company's new stress alleviation product.