How to revamp a urea plant

Revamps are performed to deliver production improvements at existing urea plants.

Revamps are performed to deliver production improvements at existing urea plants.

Rheinhütte Pumpen has further developed its GVRN sulphuric acid pump so it can also be used in high-temperature applications such as in heat recovery systems.

The Self-Cleaning Liquid Sulphur Candle Filter (LSCF) is setting a new benchmark in liquid sulphur filtration. With its innovative candle arrangement and advanced back-flushing technology, it enhances filtration rates significantly and minimises downtime for cake discharge. Jan Hermans of Sulphurnet explores the LSCF design, process parameters, and operational advantages.

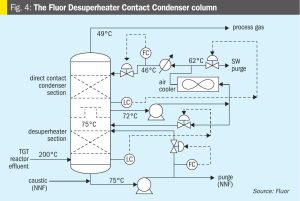

Fluor discusses the main causes, detection techniques, management methods and prevention procedures of SO2 breakthrough in the quench water system of a TGTU, with some unique design features for Fluor’s Desuperheater Contact Condenser.

M.J. Cousins of Johnson Matthey and K. Nölker of thyssenkrupp Uhde discuss the integration of LCHTM technology and the uhde® ammonia process in providing low carbon ammonia at scale, efficiently, reliably and safely today.

Risk analysis tools such as hazard identification (HAZID), is often a first step in broader risk management and is especially valuable for green ammonia, where new technologies and processes introduce novel risks. This article explores various aspects of HAZID, from the basics of hazard identification to unique considerations specific to green ammonia facilities.

A European ammonia plant, has successfully restarted following a revamp of the process gas cooling section, executed by Casale. Casale replaced the outdated boilers located downstream of the secondary reformer with three new double-tube type boilers supplied by Arvos. The new boilers were installed in the same location as the previous ones, minimising investment costs and plant modifications. The more robust and reliable design of the Casale-Arvos boilers has resulted in enhanced overall performance and reliability of the ammonia plant.

Paralloy has developed Omega technology, an advanced reformer tube design that enhances heat transfer, gas turbulence, and process efficiency. Dr Dominique Flahaut of Paralloy explores the real-world implications of Omega reformer tubes.

Maire Group says that its nitrogen fertilizer technology licensor Stamicarbon has been awarded new contracts related to its NX STAMI UreaTM technology in Canada. The first award is a process design package and the licensing of an integrated urea and diesel exhaust fluid (DEF) production plant currently being developed by Genesis Fertilizers, a farmer-owned consortium, at Belle Plaine, Saskatchewan. The plant will have a urea melt capacity of 2,500 t/d, with operations expected to begin by 2029. Also thanks to a carbon capture and sequestration unit, it will be the first proposed low-carbon nitrogen fertilizer plant in Canada. Stamicarbon will apply its proprietary flash urea melt technology to enhance operational efficiency and reliability while minimising process steam consumption. The plant will also include a DEF facility with a production capacity of 1,500 t/d.

In part 5 of this series on stripper efficiency issues we conclude the discussion with a focus on fouling inside stripper tubes.