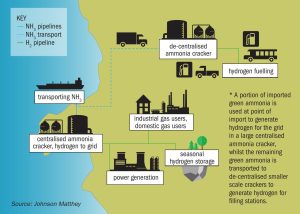

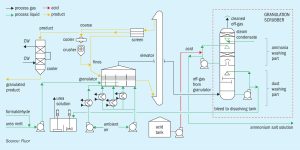

Towards an emerging hydrogen economy

New blue production schemes are available to meet the need to significantly reduce the overall carbon intensity of high-volume hydrogen and ammonia production for a large-scale emerging market. KBR, Air Liquide, Mitsubishi Heavy Industries, Casale and Johnson Matthey report on their latest technologies.