Fertilizer Industry News Roundup

Yara International has approved a project to partly convert its Pilbara plant near Karratha in Western Australia to green ammonia production.

Yara International has approved a project to partly convert its Pilbara plant near Karratha in Western Australia to green ammonia production.

CRU has appointed Mark Jeavons as the head of its CRU Sustainability division. He will be based out of London with a global remit.

Market Insight courtesy of Argus Media

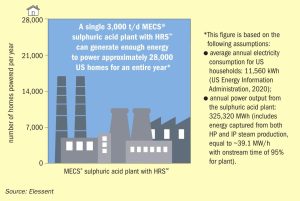

By recovering waste heat as process steam or electrical energy, technologies are available that can help sulphuric acid plants meet their energy goals. Colin Shore of Elessent Clean Technologies discusses how MECS® HRS™ technology can offer a sustainable solution to enhance sulphuric acid plant performance, while lowering its carbon emissions.

After two years of virtual events, the CRU Sulphur + Sulphuric Acid 2022 Conference & Exhibition will return to an in-person event at the World Forum, The Hague, 24-26 October 2022. CRU will be welcoming the global sulphur and sulphuric acid community to this premier annual event for networking and essential updates on the markets and technical developments that are influencing the industry.

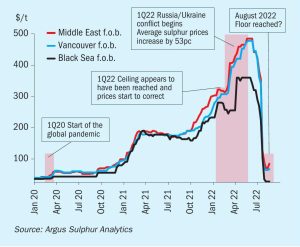

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

The US refining sector continues to face operating pressures with 1.3 million bbl/d of closures in the past three years, while sour gas sulphur production has recovered somewhat. Meanwhile, demand from copper and lithium leaching projects will increase use of sulphuric acid over the next few years.

Reduced appetite for sulphur from processed phosphates producers in China will continue to place downwards pressure on pricing in the near term. l Phosphates-based demand is likely to remain low in the second half of 2022 as issues surrounding affordability persist, slowing import requirements.

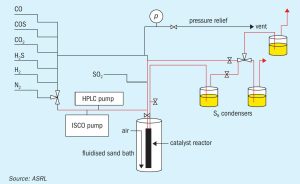

Temperature dependent rate constants for the hydrolysis of CS2 and COS across Claus Al2 O3 and TiO2 catalysts are valuable tools for the design and optimisation of new, as well as existing, sulphur recovery units. In this context, Alberta Sulphur Research Ltd (ASRL) has measured CS2 and COS hydrolysis rates over a range of temperatures for both Al2 O3 and TiO2 catalysts under start-of-run and, more recently, end-of-run first converter conditions. In this article Christopher Lavery, Dao Li, Ruohong Sui, and Robert A. Marriott of ASRL report on their methodology and the utility of the kinetics calculated from their data and draw comparisons between the start-of-run and end-of-run results.

The purpose of this article is to emphasise the lessons learned by ADNOC Sour Gas in the material upgrading of the Shah sulphur granulation plant due to severe corrosion of the aluminium components. The sulphur granulation plant was commissioned in 2015 and consists of a total of 12 granulating systems used for solidifying and granulating the liquid sulphur. The study focused on the corroded areas, namely the GX plenum chambers, the lower section of the granulator exhaust stack, the scrubber inlet and the discharge ducting.