A new generation of methanol catalysts

Haldor Topsoe has launched a new methanol synthesis catalyst, MK-181 PRIME, based on new technology developed via close study of copper-zinc interactions on the catalyst surface.

Haldor Topsoe has launched a new methanol synthesis catalyst, MK-181 PRIME, based on new technology developed via close study of copper-zinc interactions on the catalyst surface.

CRU has announced the appointment of William Etchell as Chief Financial Officer, based in the company’s London headquarters. Etchell joins CRU from GUS Holdings, a global higher education provider. Previously, he was CFO at EPG, an education services provider, and prior to that he was Group Finance Director at BPP Professional Education Group. He has over 25 years’ experience working in finance across a variety of sectors, having qualified with Arthur Andersen in the 1990s. Since then he has worked in a number of organisations including British Airways, Time Warner and Interpublic Group, as well as running his own nursery school business.

Tecnimont SpA has signed an EPC contract worth approximately e200 million with Gemlik Gübre Sanayii Anonim Sirketi for the construction of a new urea and urea ammonium nitrate (UAN) solutions plant at Gemlik, 125 km south of Istanbul. The plant will have a capacity of 1,640 t/d of granular urea and 500 t/d of UAN, and will be based on Stamicarbon urea technology, a fully owned subsidiary of the Maire Tecnimont group. The scope of work includes engineering, supply of all equipment and materials and construction and erection works. Project completion is planned within about three years of the contract beginning.

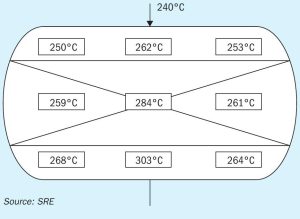

What are the limits for future single stream sulphuric acid plant capacities? H. Storch, C. Bartlett, and S. Mohsler of Outotec discuss design considerations for large capacity sulphuric acid plants with reference to the world’s largest acid plants built to date.

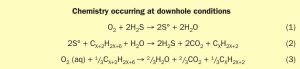

With the ongoing changes in gas field and refinery feedstock compositions, many sulphur recovery units around the world are facing turndown scenarios to such an extent that it is difficult to meet stringent environmental regulations. Equipment and instrumentation behave differently under turndown conditions, and not always in ways that are desirable. Start-ups and shutdowns can place demands on the equipment that are more severe than years of normal operation. In this article, Optimized Gas Treating, Sulfur Recovery Engineering and Comprimo share some of their learnings and experiences of these scenarios.

Siroj Loikov has been appointed First Deputy CEO of PhosAgro. Loikov, who was previously Deputy CEO in charge of international projects and personnel policy, will coordinate the work of the company’s headquarters in Moscow, its management company in Cherepovets and the company’s production sites. He will also oversee the implementation of the PhosAgro’s priority development projects and will be responsible for the appointment, development and assessment of the work of the company’s top management.

When producing from shale reservoirs, technologies such as horizontal drilling and hydraulic fracturing have been used successfully to access hydrocarbons that otherwise could not be. A less publicised issue in producing from certain hot shale gas reservoirs (T > 100°C) is the presence of H2 S and organo-sulphur compounds in the production fluids. In trying to understand the non-biogenic sources of H2 S, Alberta Sulphur Research Ltd has been involved in studying the decomposition of chemicals used in hydraulic fracturing when exposed to high temperature and high pressure.R.A. Marriott, J.J. Marrugo-Hernandez and R. Prinsloo of ASRL discuss the findings of the study.

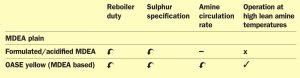

BASF has developed a new generation of promoter system compatible with MDEA solutions named OASE® yellow. The new promoter system increases the selectivity and capacity of the amine solvent, resulting in improved performance of tail gas treating units and allowing the processing of more sour crudes. A. Kern and G. Vorberg of BASF discuss two case studies demonstrating the benefits of OASE yellow.

Shell Global Solutions International BV (Shell) has awarded Worley two contracts for PT Pertamina EP Cepu’s (PEPC) new sulphuric acid plant in Indonesia. This plant is part of the Jambaran-Tiung Biru utilised gas field project for PEPC, which is a subsidiary of PT Pertamina-Indonesia’s state-owned energy company. Under the contracts, Worley will supply be supplying Chemetics’ cooled oxidation reactor (CORE) technology. This is the first time that CORE will be paired with Shell’s Cansolv SO2 capture technology. Worley gained the Chemetics technology as part of its Jacobs Energy, Chemicals and Resources acquisition last year. Cansolv controls the emissions and captures additional by-product value from the sulphur dioxide emitted from various refinery flue gas streams (such as cracking units, process heaters and boilers), sulphur plants and spent acid regeneration units. Sulphur dioxide can be recycled to the sulphur recovery unit to be produced as marketable sulphur or converted to sulphuric acid.

The Indonesian government’s decision to enforce the processing of more copper and nickel ores domestically rather than export them to China has led to the rapid development of domestic smelter capacity as well as nickel acid leaching projects.