Comprehensive coverage of the global fertilizer industry

Sulphur

Extensive and independent coverage of the global sulphur and sulphuric acid industries

Nitrogen+Syngas

Unrivalled technical and market coverage of syngas and its derivatives

Advertising

Advertise your company and products on our website or print editions

Latest from BCInsight

The shift in food and agriculture

Cover story! CASALE’s Giovanna Roviello and Francesco Baratto provide an update on the Villeta ‘green’ fertilizer project in Paraguay.

FertiCoat – the ultimate fertilizer coating?

FertiCoat is a specialised fertilizer coating developed by Omnia Specialities Australia. Its unique formulation helps prevent soil fixation and leaching losses.

How best to use enhanced efficiency fertilizers

Ronald Clemens, ICL’s Global Portfolio Manager, explains how new fertilizer technologies are boosting yields, cutting losses and supporting sustainability.

How to decarbonise coffee? Look at fertilizers!

If decarbonising coffee starts with fertilizer, why don’t they feature more in conversations about sustainable coffee? In this article, Erna Maciulis of Proba outlines practical interventions that address fertilizer emissions from coffee growing. These can unlock significant progress towards Scope 3 emissions reductions – and be easily adopted without disrupting existing farm practices.

Advanced sulphur nutrition for soybean-maize systems in Brazil

Mark Howell , Head of Agronomy & Product Development at Sulvaris, provides new insights on sulphur nutrition in soybean-maize systems.

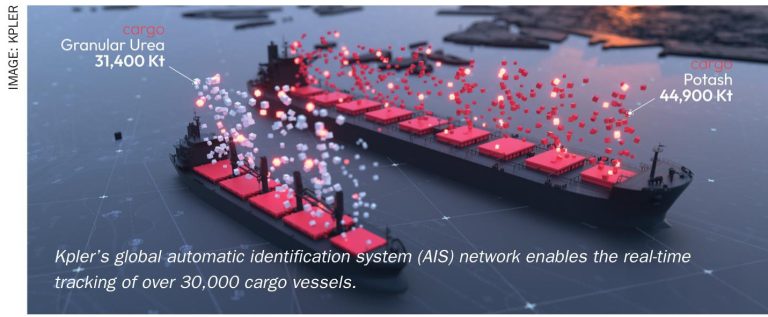

Kpler – tracking global fertilizer markets in real time

Kpler’s intelligence on fertilizer shipping and supply chains can be used to optimise operations, mitigate risks, and capitalise on emerging opportunities.

Dry bulk market to weaken in 2026?

Filipe Gouveia , BIMCO’s shipping analysis manager, looks ahead at the dry bulk market and freight rate prospects for 2026.

Wire-based additive manufacturing for HP equipment

Christof Group SBN is actively integrating advanced manufacturing solutions such as wire arc additive manufacturing (WAAM) into its portfolio for the manufacture of high-pressure equipment in urea and ammonia plants.