Comprehensive coverage of the global fertilizer industry

Sulphur

Extensive and independent coverage of the global sulphur and sulphuric acid industries

Nitrogen+Syngas

Unrivalled technical and market coverage of syngas and its derivatives

Advertising

Advertise your company and products on our website or print editions

Latest from BCInsight

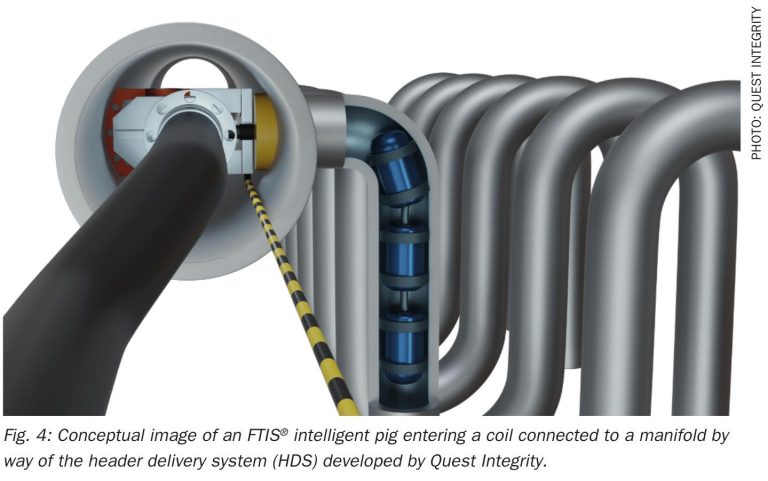

Life management of reformer convection section tubing

The convection section of a syngas reformer is vulnerable to creep, corrosion, erosion, fretting and fouling which can cause deformation, local metal loss and failures that risk plant shutdown. Inspection access is limited, but solutions are available. Quest Integrity discusses life management of the reformer convection section to reduce unplanned outages.

Voluntary carbon markets – trust and scalability

The voluntary carbon market (VCM) is maturing rapidly, and a succession of governance, standards and policy initiatives has been launched since 2020 to tackle weaknesses in integrity and scalability which have constrained uptake and undermined confidence.

Development funding for green ammonia plant

The African Development Bank has approved a $10 million loan to Hyphen Hydrogen Energy, a Namibian green hydrogen development company, to support a green ammonia project valued at more than $10 billion, and with the potential to position Namibia as a pioneer in the global green hydrogen economy. The loan, sourced from the Sustainable Energy Fund for Africa (SEFA), will support frontend engineering design (FEED) studies for solar and wind generation, battery energy storage systems, and electrolyser capacity and desalination infrastructure, aiming to de-risk the project and attract the financing required for its realisation.

Greene Tweed achieves hydrogen compression breakthrough

Greene Tweed, a leader in advanced materials and high-performance solutions, says it has achieved a significant advancement in hydrogen compression technology. The company’s newly engineered composite closed impeller set a record-breaking tip speed of 688 m/s in testing – nearly double that of traditional metallic impellers. The innovation highlights the potential of advanced composite materials to enhance performance, reduce costs, and improve efficiency in critical hydrogen pipeline infrastructure, specifically the transportation, storage and utilisation market segments.

Proton Ventures joins Barents Clean Ammonia project

Barents Blue AS has announced Proton Ventures as a new partner in the Barents Clean Ammonia Project (project formerly known as the Barents Blue project). Barents Blue says that the Dutch engineering and project development company, a pioneer in the clean ammonia industry, “will bring significant resources and industry expertise to the project and the value chain for clean ammonia, important for the realisation of Europe’s largest clean ammonia production plant located in Finnmark, Northern Norway”.

Topsoe and Maersk to set new safety standards for Power-to-X

Topsoe is partnering with Maersk Training to establish safety standards that support the emerging Power-to-X industry. Topse says that Power-to-X and the production of e-fuels are critical enablers of the transition to low-emission fuels. However, no comprehensive safety standards currently exist that address the full range of risks at these sites. Together, the two companies will develop realistic simulations, competency-based training and a strong operational culture designed to strengthen safety practices across the entire value chain. As Power-to-X technologies scale to meet global climate ambitions, both companies emphasise the need for robust, realistic and forward-looking training frameworks. The collaboration builds on Maersk Training’s nearly 50 years of experience in high-risk environments.

MoU on new urea plant

Uralchem JSC and three Indian fertiliser companies; Rashtriya Chemicals and Fertilizers Ltd (RCF), National Fertilizers Ltd (NFL), and Indian Potash Ltd (IPL) have signed a memorandum of understanding to set up a joint venture to construct a urea plant in Russia. The signing ceremony was held in New Delhi in December during a state visit by Russian president Vladimir Putin to India.

MHI successfully produces hydrogen at ammonia cracking pilot plant

Mitsubishi Heavy Industries says that it has succeeded in producing 99% pure hydrogen by cracking ammonia using steam as the heating source. The production of hydrogen at pilot scale using the steam heating was conducted at the company’s pilot plant in the Nagasaki District Research & Innovation Centre, marking a world first. By contrast to technologies that use heat from burner combustion, MHI’s steam heating system operates at lower reaction temperatures, reducing operating costs. In addition, because a combustion furnace is not required, the system offers excellent features such as the potential for miniaturisation.