Comprehensive coverage of the global fertilizer industry

Sulphur

Extensive and independent coverage of the global sulphur and sulphuric acid industries

Nitrogen+Syngas

Unrivalled technical and market coverage of syngas and its derivatives

Advertising

Advertise your company and products on our website or print editions

Latest from BCInsight

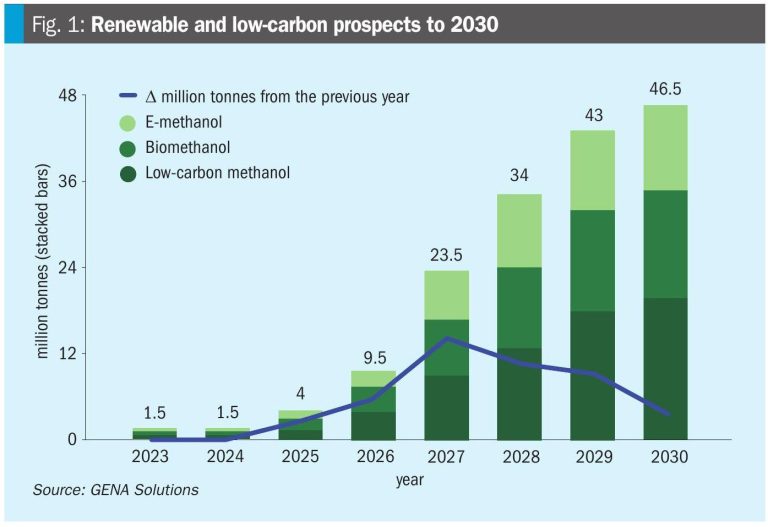

Membrane uses in methanol production

Global demand for methanol is set to increase fivefold by 2050, driven by decarbonisation in shipping and other hard-to-abate sectors. Geir Arne Johansen and Hallgeir Angel of Air Products Membrane Solutions discuss how membrane technology offers a proven, scalable solution to improve efficiency, reduce emissions, and enable compliance across both traditional and low-carbon methanol pathways.

Wire-based additive manufacturing for HP equipment

Christof Group SBN is actively integrating advanced manufacturing solutions such as wire arc additive manufacturing (WAAM) into its portfolio for the manufacture of high-pressure equipment in urea and ammonia plants. WAAM technology is especially suitable for niche materials customised for high corrosion resistance to carbamate solution and addresses the need for fast and tailored manufacturing of spare parts explain Aleksandra Gavrilovic-Wohlmuther and Serhiy Budnyk of Christof Group SBN.

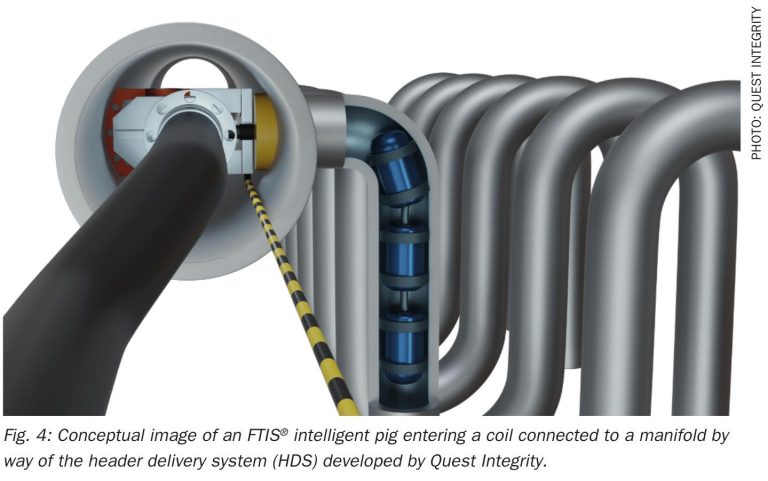

Life management of reformer convection section tubing

The convection section of a syngas reformer is vulnerable to creep, corrosion, erosion, fretting and fouling which can cause deformation, local metal loss and failures that risk plant shutdown. Inspection access is limited, but solutions are available. Olivia Chung, Tim Haugen, and Charles Thomas of Quest Integrity discuss life management of the reformer convection section to reduce unplanned outages.

EU tackles rising fertilizer costs under CBAM through targeted tariff relief

Recent developments show the Carbon Border Adjustment Mechanism (CBAM) remains active for fertilizers, but the European Commission proposes tariff reductions to offset import costs. Tariff suspension details The Commission will temporarily suspend remaining Most-Favoured-Nation (MFN) tariffs on ammonia, urea, and certain other fertilizers. Import tariffs from most-favoured nations stand at 6.5%, excluding higher staged tariffs […]

US intervention spotlights Venezuela fertilizer assets

Venezuela’s nitrogen industry faces uncertainty from US military intervention, as outlined in a recent CRU analysis. Strategic facilities State-owned Pequiven manages three northern coastal plants with 2.4 Mt annual ammonia capacity and 3.0 Mt urea capacity. These sites link directly to PDVSA pipelines and nearby natural gas operations. Historical disruptions and 2023 rebound US sanctions […]

DTC / IPOS conference

You have been granted access to the recent editions of Sulphur and Nitrogen+Syngas magazines NovDec issues. Please download here for Sulphur and here for Nitrogen+Syngas. For 30 days access take out a Free Trial.

Press Release: NEXTCHEM (MAIRE) announces two awards in China based on its proprietary NX STAMI Nitrates and NX STAMI Urea technologies, advancing the fertilizer industry

NEXTCHEM (MAIRE) to provide the license and PDP for a new nitric acid plant in China and technical assistance services for the revamping of a nitrogen fertilizer complex

Press Release: Metso signs landmark order for a major copper smelter delivery in Asia

Metso wins major order for delivery of engineering and key process equipment for new primary copper smelter investment in Asia