Sulphur 422 Jan-Feb 2026

29 January 2026

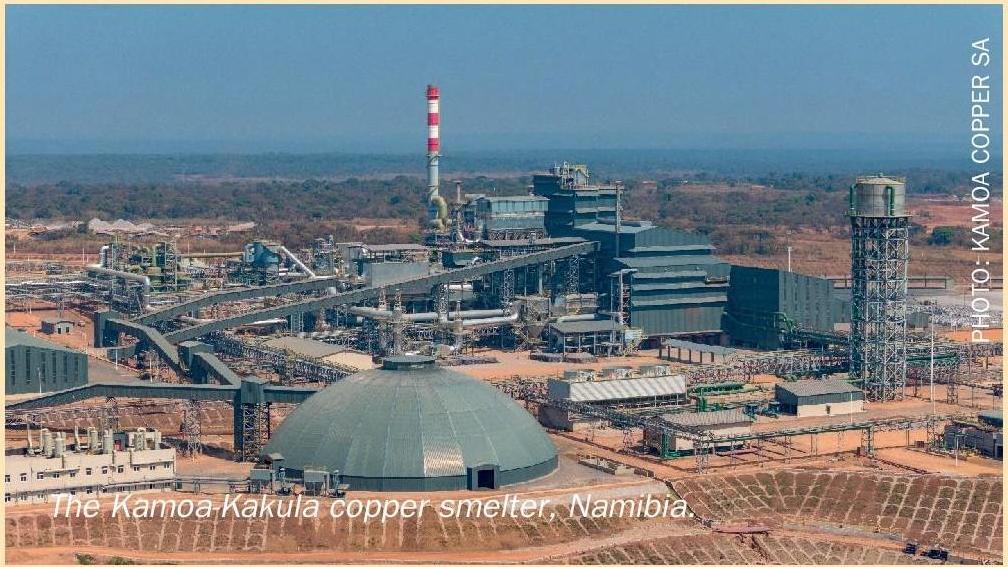

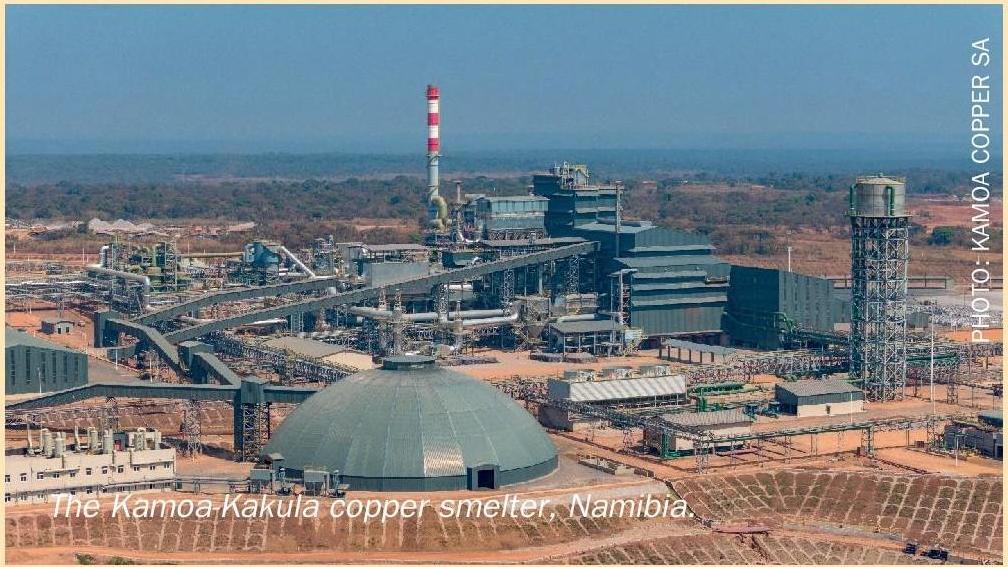

First production from Kamoa-Kakula smelter

Ivanhoe Mines says that the first copper anodes were produced by Kamoa-Kakula’s 500,000 t/a direct-to-blister copper smelter on December 29, 2025, approximately five weeks after the commencement of the smelter’s heat-up and one week after the first feed of concentrate.

Ivanhoe Mines’ Founder and Executive Co-Chairman Robert Friedland commented: “The first production of copper anodes from our world-class smelter is a defining moment for Kamoa-Kakula… This achievement is the culmination of a $1.1 billion investment, 18 million man-hours of disciplined execution, and an outstanding health and safety record that reflects the professionalism and commitment of everyone involved. This facility will proudly deliver the highest-quality Congolese copper anodes to the international markets, setting a new global benchmark for scale, efficiency, and sustainability. I want to extend my sincere thanks to the extraordinary Kamoa Copper team, as well as our contractors and partners from across the world whose expertise, innovation, and teamwork made the design and delivery of this state-of-the-art facility possible. Together, we have built something exceptional that will serve global consumers for generations to come.”

Smelter ramp-up is under way to achieve a steady-state rate of 500,000 t/a of 99.7%-pure copper anode, making it the largest copper smelter in Africa, and will continue throughout 2026, with completion expected towards year-end. Kamoa-Kakula’s copper production is estimated at between 380-420,000 t/a of copper in 2026, with the mid-point of 400,000 t/a of copper representing approximately 80% of the smelter’s total capacity. Kamoa-Kakula’s operating margins are set to expand due to reduced logistics costs from the smelter, as well as sales of by-product sulphuric acid. The smelter is expected to produce up to 700,000 t/a of high-strength sulphuric acid at steady-state operations, which will be sold locally. Sulphuric acid is in high demand by other mining operations across the Central African copper belt, especially following the export ban of acid by Zambia in September 2025. Spot acid prices have reached as high as $700/t in Kolwezi in recent months. The first sale of acid by Kamoa-Kakula has already taken place, with the first delivery expected in the coming weeks.