Fertilizer International 530 Jan-Feb 2026

23 January 2026

FertiCoat – the ultimate fertilizer coating?

VALUE-ADDED MARKET

FertiCoat – the ultimate fertilizer coating?

FertiCoat is a specialised fertilizer coating developed by Omnia Specialities Australia for granular, liquid, and soil applications. The coating’s unique biostimulant formulation, by helping to reduce soil fixation and leaching losses, makes key nutrients more available for plant uptake.

In today’s economic landscape, growers face constant pressure to optimise their inputs and maximise crop yields. Nutrient use efficiency in particular – by indicating how well inputs are delivered to the crop – plays a pivotal role in measuring and enhancing the performance of applied fertilizers.

To help address these farm productivity concerns, Omnia Specialities Australia has introduced FertiCoat, an effective biostimulant coating for fertilizers. Designed for ease of application, its primary goal is boosting crop yields, and therefore farm profits, by improving fertilizer efficiency.

The unique combination of biostimulants present in FertiCoat – including seaweed, humates, fulvates and amino acids – promotes plant growth and enhances crop resilience to both biotic and abiotic stresses. FertiCoat also acts to increase plant nutrient uptake through the root system.

FertiCoat serves as an excellent coating for granular fertilizers (NP, NPK and urea) and functions as an effective additive for liquid fertilizers like urea ammonium nitrate (UAN). Crucially, when added to urea, FertiCoat ensures that nitrogen stays in root zone, preventing wastage and nutrient loss through volatilisation and/or leaching.

Multiple benefits

FertiCoat offers a range of agronomic and physical benefits.

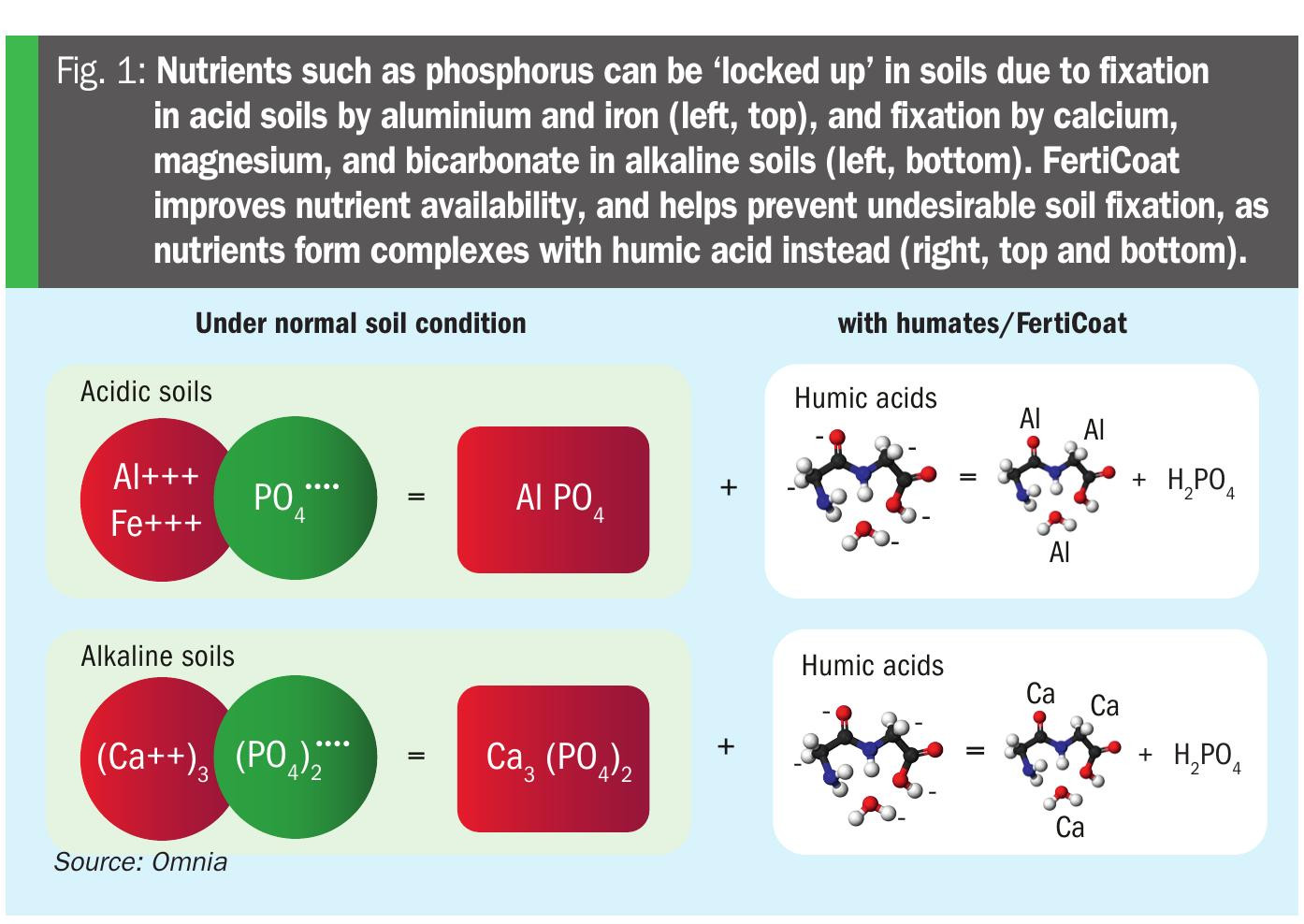

Agronomically, it acts to improve both nutrient retention and soil fixation. In sandy soils, the humic acid present in FertiCoat helps prevent the loss of water-soluble nutrients to leaching by providing a charged surface able to retain these. FertiCoat also complexes with nutrients, particularly phosphorous, to prevent these becoming fixed or ‘locked up’ in soils. In acidic (low pH) soils, for example, it acts to stop phosphorus fixation by aluminium and iron. Similarly, it helps avoid fixation by calcium, magnesium, and bicarbonate in alkaline (high pH) soils (Figure 1).

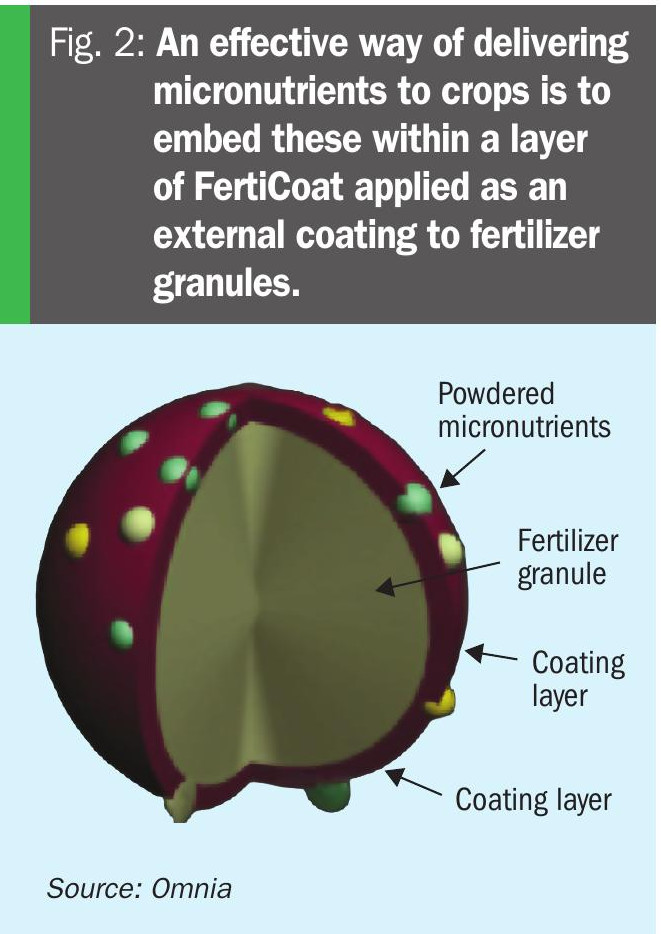

Physically, FertiCoat also improves fertilizer handling by reducing dust and caking, improving flowability, and enhancing granule hardness, while also providing an effective carrier for micronutrient additives (Figure 2).

Preventing crop burn

When integrated with UAN, FertiCoat brings tangible advantages for both soil applied and foliar applications. Moreover, its buffering effects on nitrogen content are conducive to microbial and mycorrhizal activity in soils.

For crops like wheat, UAN is commonly applied as a foliar solution. Under specific conditions, however, this may have a damaging effect on yield potential due to crop burn. Valuably, the addition of FertiCoat significantly reduces the likelihood of leaf burn or scorch by neutralising the harmful effects of biuret. The humic and fulvic contents of FertiCoat also promote foliar uptake and minimise nitrogen volatilisation.

Ease of application

FertiCoat can be applied to fertilizer granules using various equipment, such as granulation drums, coolers, coating drums, blenders, screw augers, or conveyors. Omnia also offers a dedicated FertiCoat applicator system with a controller, pump and double spray jets for good coating coverage (see photos).

Crop trial results

Worldwide crop trials have provided independent evidence of FertiCoat’s ability to increase yields and generate higher revenues.

FertiCoat’s efficacy was demonstrated in a series of crop trials on wheat and maize over three years (2008-2010) at 25 locations in South Africa. It was applied in conjunction with micronutrients as a coating to NP/NPK fertilizer granules. FertiCoat delivered a 4.1-6.2% and 4.1% yield improvement for wheat and maize, respectively, versus the untreated control, in trials located in South Africa’s Central and Cape regions.

“From the South African data, there is a 96% probability of getting a 300% or greater return on investment (ROI) from FertiCoat,” said Omnia.

In Australia, positive results were obtained using FertiCoat treated urea (coating applied at 5 litres/tonne) in a pasture trial in Victoria. FertiCoat treatment increased pasture dry matter by 4.1 kg/day, around 11% greater than the control, for a 100 kg/ha urea application rate.

In ballpark terms, this extra pasture yield could translate to an increase in annual farm income of more than AUD 472/ha when used for grazing by a dairy herd, based on the following calculation:

• 4.1 kg dry matter/day = 8.2 litres of extra milk/day

• 8.2 litres/day milk x 8 months = 1,968 litres/ha/year extra = 78.7 kg more milk solids (about 4%)

• 78.7kg milk solids = AUD 472.2/ha/annum (assuming 1 kg of milk solid = about AUD 6).

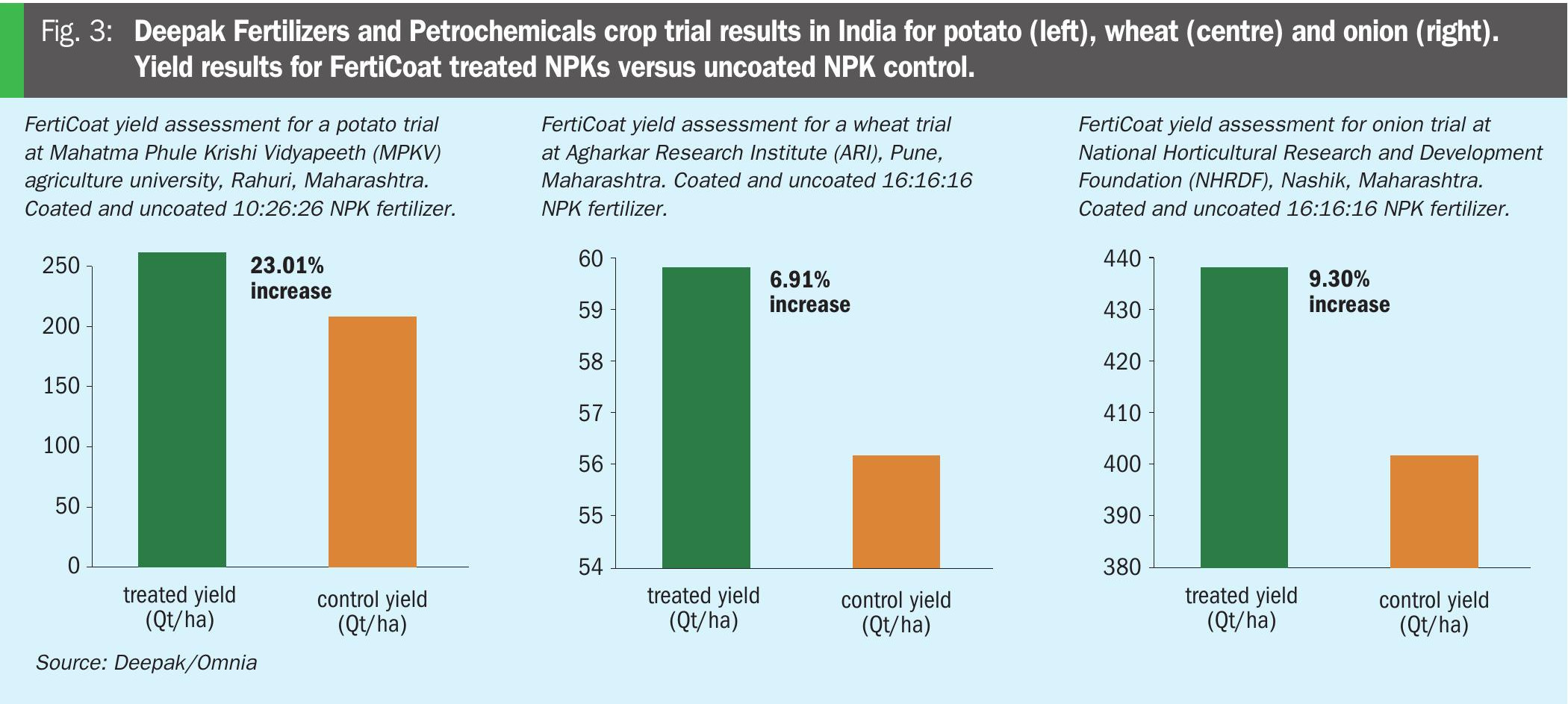

Elsewhere, leading Indian fertilizer manufacturer Deepak Fertilizers and Petrochemicals Corporation Limited (DFPCL) has been producing NPK fertilizers coated with FertiCoat, after extensive agronomic trials showed significantly higher yields across a range of crops. These included yield improvements for potato, wheat and onion of around 23%, 7% and 9%, respectively, with FertiCoat treated NPKs, relative to the untreated control (Figure 3, left to right).

At the forefront of biostimulants

Omnia Specialties Australia is a leading manufacturer of speciality fertilizers, biostimulants (humates, fulvates, kelp), micronutrients, and foliar fertilizers. Based in Morwell, Victoria, the company is Australia’s largest producer of humate and fulvate products and exports to more than 30 countries.

With a focus on soil health, Omnia utilises the best quality leonardite to produce highly concentrated humic acids. The company controls every step of the process, from mining leonardite in the Gippsland Basin – one of the richest sources of humic substances in the world – to developing and testing advanced biostimulant products to ensure these meet strict agronomic and environmental standards. Omnia’s team of agronomists and scientists also work closely with growers, offering tailored advice and technical support.

FertiCoat is well positioned within the fast growing biostimulants sector, with humic substances and seaweed extracts leading the market. This innovative coating also supports the shift to regenerative agriculture – helping growers get more from their fertilizer inputs by reducing losses, improving soil health and encouraging microbial diversity.

FERTICOAT: KEY BENEFITS AND FEATURES

A different kind of coating

FertiCoat isn’t just another fertilizer additive, according to its manufacturer Omnia:

“It’s a carefully engineered coating that brings together humic and fulvic acids from Australian leonardite, seaweed extracts, amino acids, and proprietary polymers. This blend is designed to help plants get the most out of every granule of fertilizer.”

The humic acids in FertiCoat hold onto nitrogen, keeping it in the root zone and reducing losses to the air and water. At the same time, phosphorus stays available for plant uptake, and the seaweed and amino acids boost root growth and soil life.

FertiCoat is also easy to use – with urea, NPK and UAN fertilizers – whether applied as granules or liquids. For liquid UAN, it can even help prevent leaf burn, a common headache for growers.

Agronomic and environmental benefits

• Improved nutrient use efficiency: Makes applied nutrients more available to plants.

• Reduced nutrient lockup: Prevents nutrients like phosphorous from becoming fixed in soils and unavailable to crops.

• Less leaching: Helps retain water-soluble nutrients in the root zone.

• Improved yields: Extensive trials consistently demonstrate significant increases in crop yields.

• Micronutrient application: an excellent agent for coating micronutrients directly onto fertilizer granules.

Physical/handling advantages

• Dust absorption: Absorbs up to 3% of dust, which translates to an additional 30 kg/t of fertilizer output.

• Improved flowability: Dust suppression leads to better product flow.

• Reduced caking: Stacking tests show no hard lumps or caking in storage.

• Excellent storability: Treated granules (standard 6 litres/tonne coating rate) show less than 1% breakdown after 10 heat cycles.

• Rapid drying: Coating dries quickly after application.

• Granule hardness: The coating either improves or maintains the hardness of fertilizer granules.

• Reduced machinery buildup: Significantly reduces sticking and buildup in blending and coating machinery, leading to less downtime for maintenance.

Liquid application with UAN

When mixed with urea ammonium nitrate (UAN) for foliar application, FertiCoat offers:

• Reduced leaf scorch risk: Significantly mitigates the risk of leaf burn commonly associated with foliar UAN applications, allowing for potentially higher application rates.

• Improved nitrogen uptake: The addition of humic acids has been proven to increase nitrogen uptake by the plant.

• Increases yield potential: Improved nutrient uptake plus lower crop stress contribute to higher yields.