Fertilizer International 529 Nov-Dec 2025

21 November 2025

Smarter fertilizer handling

SHIP UNLOADING

Smarter fertilizer handling

Fertilizers are tough on equipment – dusty, corrosive, and hard to manage. Siwertell’s enclosed systems handle them cleanly and efficiently, with minimal waste or emissions. From ship to storage, the company aims to ensure safe, reliable, high-capacity fertilizer transfers.

A large volume global market

The bulk fertilizer market is largely driven by population growth, with demand strongly tied to the adjacent grain, food and farming sectors. The same is true for fertilizer raw materials, which are subject to the same market forces as the finished product.

Siwertell – which first introduced its screw-type unloaders to the dry bulk handling market more than 40 years ago – is ready to meet this growth with safe, sustainable, high-volume fertilizer handling systems.

The most common dry bulk fertilizers traded and shipped globally include urea, monoammonium and diammonium phosphate (MAP/DAP), muriate of potash (MOP) and NPKs.

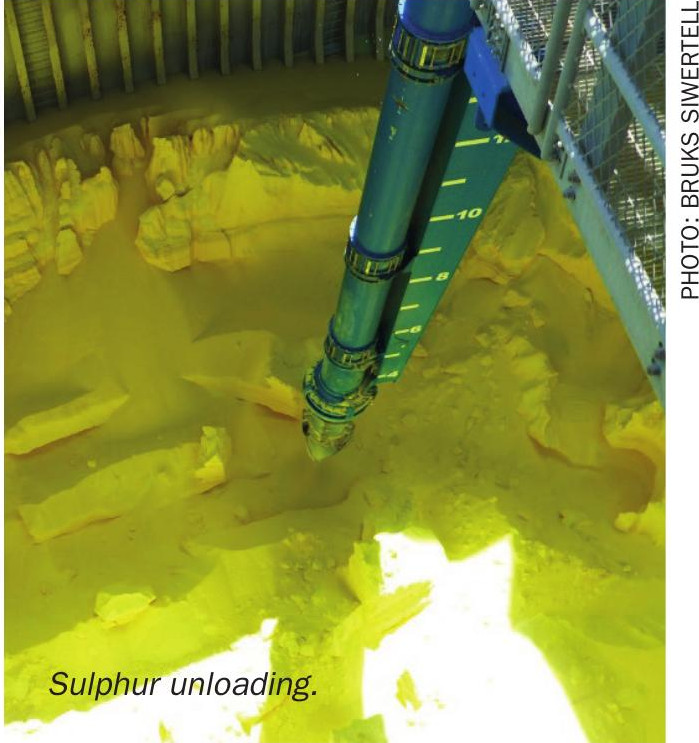

These finished fertilizers, together with fertilizer raw materials such as sulphur and phosphate rock, are generally dusty to handle. Many are also hydroscopic with this leading to clumping and crusting in the hold during shipping, if exposed to moisture.

This affects their free-flowing characteristics and, consequently, port fertilizer handling systems need to be able to cope with compaction when discharging bulk fertilizers from the hold, as well as the harsh properties of the various fertilizer product types. Bruks Siwertell screw-type ship unloaders are robust and designed to meet these needs – enabling them to efficiently discharge even the most heavily compacted and corrosive cargoes.

It’s a difficut balancing act, as Bertil Andersson, Bruks Siwertell’s sales manager, has explained previously (Fertilizer International 475, p44):

“Handling dry fertilizers and fertilizer raw materials in bulk poses some challenges. The three key aspects to handling fertilizers successfully are minimising cargo degradation, limiting environmental impacts and maintaining high safety standards.

“However, to provide the greatest commercial benefits, fertilizer handling technology also needs to provide the high capacity and efficient through-ship performance that operators expect. Totally enclosed systems with high performance screw-type unloaders are leading the way, as they have the advantage of being able to satisfy all these demands.

“Many operators and sectors have adopted and embraced this new technology!”

Sustainable handling in changing times

Strict environmental regulations governing bulk fertilizers are generally in force at ports and terminals.

In response to these requirements, Siwertell’s fertilizer handling systems offer totally enclosed conveying lines from the ship to the shore – ensuring that material spills are eliminated and dust creation and emissions are kept to an absolute minimum.

The company’s range of ship unloaders, loaders, conveyors, and storage and reclaiming systems are making significant inroads into the worldwide trade in bulk fertilizers, an industry that has traditionally relied on grab cranes and bucket systems at its discharge ports.

Behind the switch by industry operators is the desire for increased efficiency, improved safety standards and a much cleaner operating environment. Indeed, the adoption of Siwertell equipment is often driven by increasingly stringent environmental protection regulations and the corresponding need to ensure sustainable fertilizer handling.

A vital bulk commodity with handling issues

Agriculture relies on bulk fertilizers, which are primarily made from nitrogen, phosphorus and potassium compounds along with sulphur. Dry bulk fertilizer handling systems need to have wide-ranging capabilities as they:

• Must minimise cargo degradation and environmental impacts

• Yet keep the risk of fire and explosion as low as possible

• While dealing with these hazards in a way that presents no risk to personnel, ships and terminal infrastructure.

The dusty nature of bulk fertilizers and fertilizer raw materials can create serious localised environmental problems when discharged using grab cranes or bucket systems. Siwertell, in contrast, offers extremely clean bulk fertilizer ship unloading, loading and conveying systems designed to eliminate spillage and keep dust emissions to an absolute minimum.

The company, thanks to its long track record and knowledge of bulk handling, combined with some unique capabilities, has become a leading global supplier of safe, totally enclosed unloading systems for fertilizers and associated raw materials.

In sulphur unloading and transfers, for example, the proprietary Siwertell Sulphur Safety System (4S) detects and extinguishes fires early – safely containing them by shutting down the system to stop their spread. Fire detectors are installed along the length of the conveying line. These automatically trigger the fire-extinguishing system and stop the conveyors to prevent any fire from spreading to storage areas. Furthermore, the system’s extra-thick steel casings can withstand an explosion, while venting valves relieve the resulting pressure. The incorporation of robust stainless-steel components also minimises corrosion.

Serving India’s fast-growing dry bulk markets

In many countries, the environmental performance of Bruks Siwertell’s systems has delivered its industry customers an operational lifeline when handling bulk fertilizers. The company is involved in almost all of India’s dry bulk markets, for example, with particular prominence in the bulk fertilizer industry (Fertilizer International 475, p44).

Major equipment deliveries to the fertilizer sector include four Siwertell ship unloaders for handling phosphate rock and sulphur imports, important ingredients in domestic fertilizer manufacture.

Working hard to secure these imports, for example, is Paradeep Phosphates Limited (PPL), a leading fertilizer industry company operating in the state of Odisha, India. Bhubaneswar-headquartered PPL is a major phosphate fertilizer manufacturer, being one of Asia’s largest producers of diammonium phosphate (DAP).

Since 2006, a rail-mounted Siwertell 640 D-type ship unloader has been serving the company. This machine has been a critical part of the port’s environmental transformation, supporting a switch from open-air handling of sulphur with a bucket-type unloader to safe, fully enclosed, dust-free operations.

The installation has now been in operation for more than 15 years and has been successful at speeding up vessel turnarounds for PPL, and thereby reducing freight costs and demurrage, achieving a return on investment in a short space of time.

Building on this success, in 2021, Bruks Siwertell won a contract to deliver a second Siwertell 640 D-type ship unloader to PPL, enabling the company to keep pace with its expansion plans and increased volume demand (see box).

Helping india expand fertilizer raw material imports

Doubling capacity for Paradeep Phosphates Limited

PPL’s new rail-mounted ST 640-D unit installed in 2021 has the capacity to discharge sulphur from vessels of up to 60,000 dwt in size at a rated capacity of 1,500 t/h. Alternately, it handles sulphur and phosphate rock cargoes at a rate of 1,200 t/h and muriate of potash (MOP) at 1,050 t/h. It has a similar set up as the existing unit, but also features updated, modern components and Industrial Internet of Things (IIoT) capabilities.

Both units, like all Siwertell ship unloaders that handle sulphur, are fitted with the Siwertell Sulphur Safety System (4S), which was first developed more than 30 years ago to minimise the risk of explosions when handling this extremely volatile and corrosive dry bulk material in a contained environment. Siwertell technology is the only ship unloading system able to offer safe and totally enclosed sulphur handling.

PPL’s new unloader works on the same jetty as Siwertell’s previous delivery and doubles its material handling capacity, delivering a very efficient terminal with outstanding environmental credentials. The high efficiency of both Siwertell machines means that vessel unloading times are kept to an absolute minimum, reducing demurrage while maximising the utilisation rate of the jetty.

Long-serving machines for IFFCO

Since 2011, Paradeep Port has also been served by a high-capacity, rail-mounted Siwertell ST 790-D unloader delivered to the Indian Farmers Fertiliser Cooperative Limited (IFFCO). IFFCO is another leading player in India’s fertilizer industry and runs one of the world’s largest DAP plants with a production capacity of around two million tonnes annually.

The plant needs raw materials, particularly phosphate rock and sulphur. This is where the Siwertell ship unloader delivers. This unit can unload sulphur from vessels up to 75,000 dwt at 1,800 t/h. Dust emissions have been prevented by replacing the previous grab crane a fully enclosed conveying system, further improving the environmental conditions at the port.

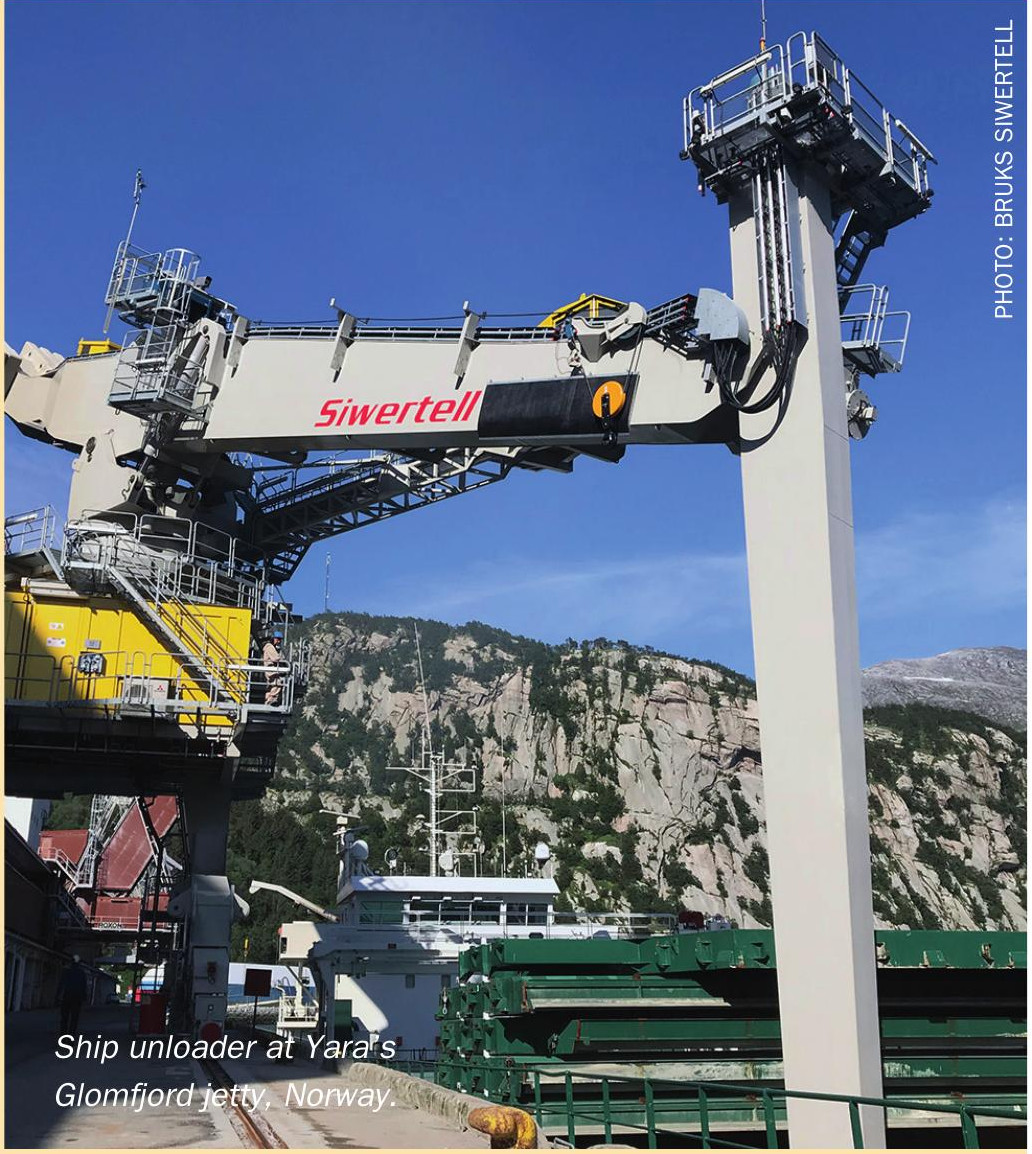

Long term partnership with Yara

Norway’s leading mineral fertilizer producer, Yara International, operates the Glomfjord fertilizer plant within the Arctic Circle. When greater capacity was required, the company ordered a new replacement ship unloader from Bruks Siwertell, its original supplier. The new machine needed to handle demanding fertilizer raw materials, meet strict environmental criteria, manage high prevailing winds, and operate successfully at extremely low temperatures.

Yara now operates a rail-mounted Siwertell ST 490-M ship unloader at Glomfjord. The unloader is equipped with a dust-suppression system and an advanced electrical control unit, including Siwertell’s SiMon monitoring system (see box).

Efficient, safe unloading in the Arctic Circle

For more than 30 years, Yara’s Glomfjord fertilizer plant within the Arctic Circle has employed a well-maintained, high-performance Siwertell ship unloader. When greater capacity was required in 2018, the company looked to Bruks Siwertell to meet its needs (Fertilizer International 504, p38).

The challenge

Glomfjord is the world’s most northerly fertilizer plant. Served by its own harbour, operator Yara needed to increase capacity and was looking to retire its long-serving Siwertell unit, delivered in the early 1980s.

The new unloader had to be able to handle demanding dry bulk materials such as phosphate rock and potash. It also needed to meet strict environmental criteria, manage high prevailing winds and operate successfully in the extremely low temperatures of the Arctic Circle.

Compounding the challenge was limited jetty space. Any new machine would have to fit into the existing footprint of the older model, while providing higher capacity. It would also have to be lifted into place using a heavy-lift vessel.

The solution

To ensure that any new unloader would fit the site and meet the installation requirements over the whole travelling length, Bruks Siwertell conducted a 3D scan of the Glomfjord jetty. After confirming that it would be suitable, Yara ordered a rail-mounted Siwertell ST 490-M ship unloader.

To ensure that Yara’s production schedules were not interrupted, the unloader needed to be installed, tested, commissioned and fully operational within a pre-planned maintenance stop of just one week.

Able to serve vessels of up to 20,000 dwt, the new unloader is equipped with a dust-suppression system and an advanced electrical control unit, including the Siwertell monitoring system, known as SiMon. With a PC-based interface, this offers quick troubleshooting, easy unloader start-up, an analysis tool for problem-solving, a preventive maintenance guide and remote access by Siwertell engineers.

The results

Just 18 months from the order being placed, Yara was very satisfied to have the new machine up and running and meeting the required stringent environmental standards – all without a single day of delay.

The new unloader maintains a continuous rated discharge of 600t/h, with a peak capacity of 700t/h, depending on the material being handled. Yara plans to upgrade its belt conveyor system to match the capabilities of its new unloader.

The delivery continues a long-standing partnership with the company and includes follow-up service visits and a comprehensive set of spare parts. With capacity to spare, Yara expects to get another three decades of service from its new Siwertell system.

Efficiency and reliability for all fertilizer applications

Bruks Siwertell’s tailor-made ship unloaders, ship loaders and conveying systems provide the perfect bulk handling arrangements for all sizes of fertilizer operations. Reliability, efficiency and excellent through-ship performance deliver significant commercial benefits.

The company’s machines offer an integrated, uncompromising and economic option for fertilizer handling, according to sales director and industry veteran Bertil Andersson (Fertilizer International 475, p44):

“With the exception of the standardised conveyor system, Siwertell unloaders are typically tailor-made to suit the individual requirements of operators. Our unloaders have a small physical footprint and are lightweight when considered alongside other technologies with comparable through-ship rates.

“This lowers the investment needed in jetty construction, adding to their overall competitiveness. With effective maintenance, timely replacement of worn parts and periodic upgrades, our systems can be expected to give excellent performance over many decades.

“In addition to delivering stand-alone systems, Bruks Siwertell can provide fully-compatible downstream and upstream conveying solutions, ideally matched to the unloader or loader.

“We also offer design, construction and installation services. This is valuable for customers planning complex import/ export terminals with high capacity loaders, unloaders, conveying systems and flexible storage arrangements.

“Our market-leading totally enclosed unloading and conveying systems minimise dust emissions and eliminate spillage. This means there is no wastage and the operator receives all of the shipped cargo.

“Finally, clean-up costs are also minimal or non-existent as the ship, terminal and surrounding areas remain unpolluted. The working conditions for crew and port personnel are greatly improved too.”