Fertilizer International 528 Sep-Oct 2025

13 September 2025

Alternatives to flotation in potash processing

POTASH MINING & TECHNOLOGY TRENDS

Alternatives to flotation in potash processing

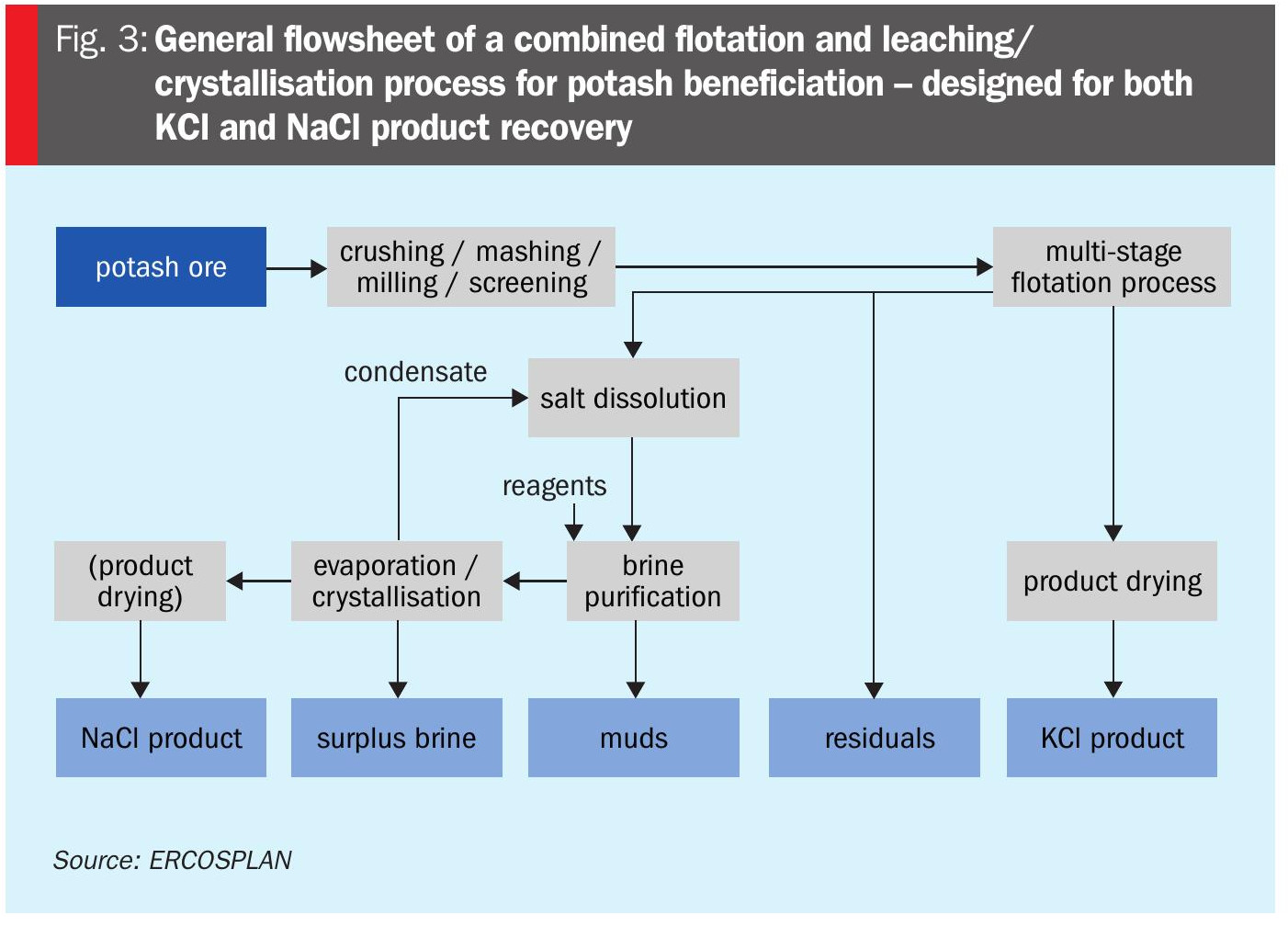

Globally, froth flotation is the most popular potash beneficiation process used in the production of saleable potassium chloride. Leaching /crystallisation is, however, better suited to complex and hard-to-liberate potash ores, according to ERCOSPLAN’s Dr Eike Kaps. Flotation can also be combined with leaching/crystallisation to optimise potash resource use and manufacture commercial potassium chloride and sodium chloride products.

Potash, as one of the main components of multi-nutrient fertilizers, is essential for plant growth. With an annual production capacity of 80 million tonnes, it is one of three major crop nutrients – alongside phosphorus and nitrogen – that help secure the food supply of billions of people.

Muriate of potash (MOP) occurs naturally as the mineral sylvite (potassium chloride, KCl) in mineral salt deposits in combination with other minerals such as:

• Halite (NaCl)

• Anhydrite (CaSO4)

• Kieserite(MgSO4 x H2O)

•Polyhalite (K2SO4 x MgSO4 x 2CaSO4 x 2H2O).

Potash therefore needs to be separated out from these mineral mixtures before it can be turned into a primary product for fertilizer production.

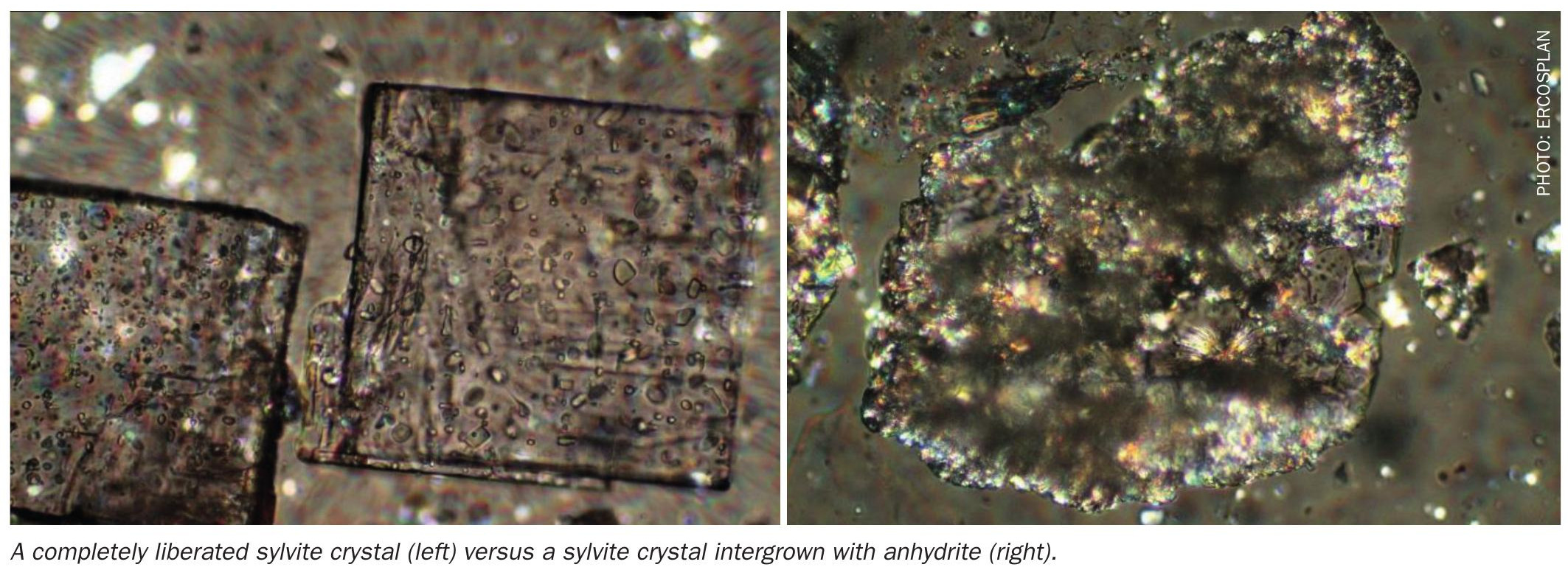

Globally, froth flotation is the most widely used beneficiation process for separating sylvite from accessory minerals to generate a useable and saleable potassium chloride product (Figure 1). It is commonly practiced in several major potash production centres worldwide.

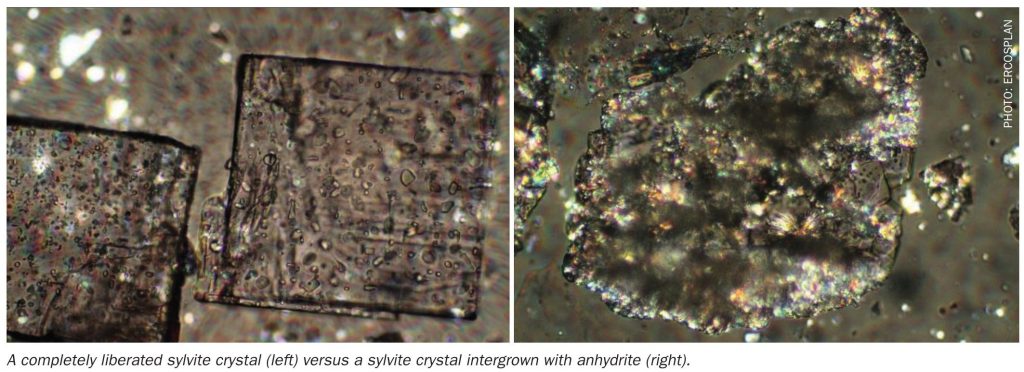

Flotation is generally suitable for potash beneficiation when the KCl occurs in a relatively simple mineral mixtures and is also liberated from the secondary components present – i.e., the crystals of the individual minerals are not intergrown.

However, flotation is not suitable for ore types where the sylvite crystals are not liberated from gangue minerals. If the Sylvite is intergrown with anhydrite (main photo, right) and halite crystals, for example, it is generally not possible to separate the sylvite from these via a mechanical separation method – such as flotation – and obtain a potassium chloride product.

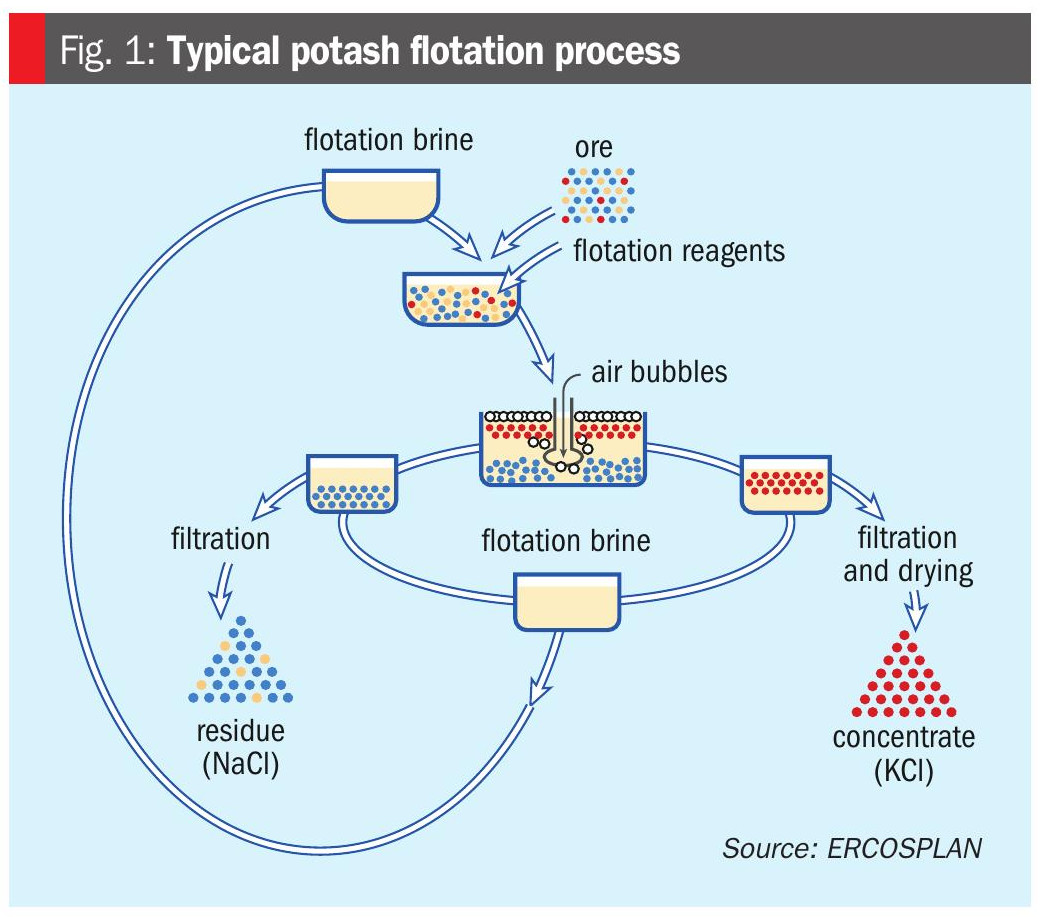

In such cases, more complex chemical separation methods, like leaching and crystallisation, are necessary to separate the sylvite from the secondary components. Leaching and crystallisation work by exploiting the different solubility behaviour of individual minerals.

In potash processing, the ore is typically leached with a hot brine saturated with NaCl (sodium chloride) but undersaturated with KCl. While the KCl in the ore dissolves in the hot brine, both NaCl and the CaSO4 remain undissolved as solids. After leaching, hot brine saturated with KCl and NaCl is firstly separated from the coarse solids and then clarified to remove the fine solids.

Pure KCl is then crystallised out in a subsequent vacuum cooling crystallisation stage. This selective crystallisation occurs because the solubility of KCl declines with decreasing temperature, whereas the solubility of NaCl changes little during cooling and therefore remains in solution. A typical potash leaching/crystallisation process is shown in Figure 2.

As well as intergrowth of different minerals, the complexity of the mineral salt mixtures can also pose challenges for flotation-based potash beneficiation. The ‘floatability’ of the potash ore is generally limited if many different minerals are present – for example, when sylvite, halite, kieserite and polyhalite are all intermixed together. For such ore types, there is no flotation flowsheet available that can separate out all these minerals. Instead, pure and saleable KCl products can only be obtained by using a leaching and crystallisation process.

Improving sustainability and resource use

It is not just the ease of beneficiation that is important. Sustainability should also always be kept in mind during process selection and design.

Sustainability can generally be improved by increasing the overall yield of the process – as this reduces environmental impacts by lowering the requirement for utilities (water, gas, steam, chemicals etc.) and even the physical footprint of the plant itself. Many successful sustainability improvements have been made through process adaptions in recent decades.

The recovery of by-products such as sodium chloride, to reduce waste and increase utilisation of the whole ore, is another approach that improves resource use and sustainability. It is conceivable that the demand for NaCl will increase rapidly in the years ahead – due to the development of new types of rechargeable batteries based on sodium ions and not on lithium.

To meet the expected rise in demand, new beneficiation schemes will need to be designed that enable existing potash plants to be adapted to recover NaCl as a saleable product as well as KCl. This could be achieved via a leaching/crystallisation process only, for example, or by combining flotation with leaching/crystallisation, as shown in Figure 3.

In conclusion, the combination of mechanical separation processes, such as froth flotation, with chemical separation processes, like leaching/crystallisation, can optimise the utilisation of potash deposits and improve margins by manufacturing different salt products such as potassium chloride and sodium chloride.

Acknowledgement

This article is based on a presentation given by Dr Eike Kaps at this year’s CRU Phosphates+Potash Expoconference, Orlando, Florida, in April. The call for papers for next year’s event in Paris, 13-15 April 2026, is now open: events.crugroup. com/phosphates/call-for-papers