Fertilizer International 528 Sep-Oct 2025

11 September 2025

What next for phosphorus innovation?

PHOSPHATES AND THE FUTURE OF FARMING

What next for phosphorus innovation?

Phosphorus supports robust crop yields and plays a direct role in food security. However, while we have made considerable progress in how we produce and apply phosphorus-rich fertilizers, there is plenty of scope to develop new products in the future. Dr Karl Wyant, Nutrien’s Director of Agronomy, looks at past innovations and what the future holds for phosphorus in farming.

Phosphate mining at one of Nutrien’s North American operations.

Introduction

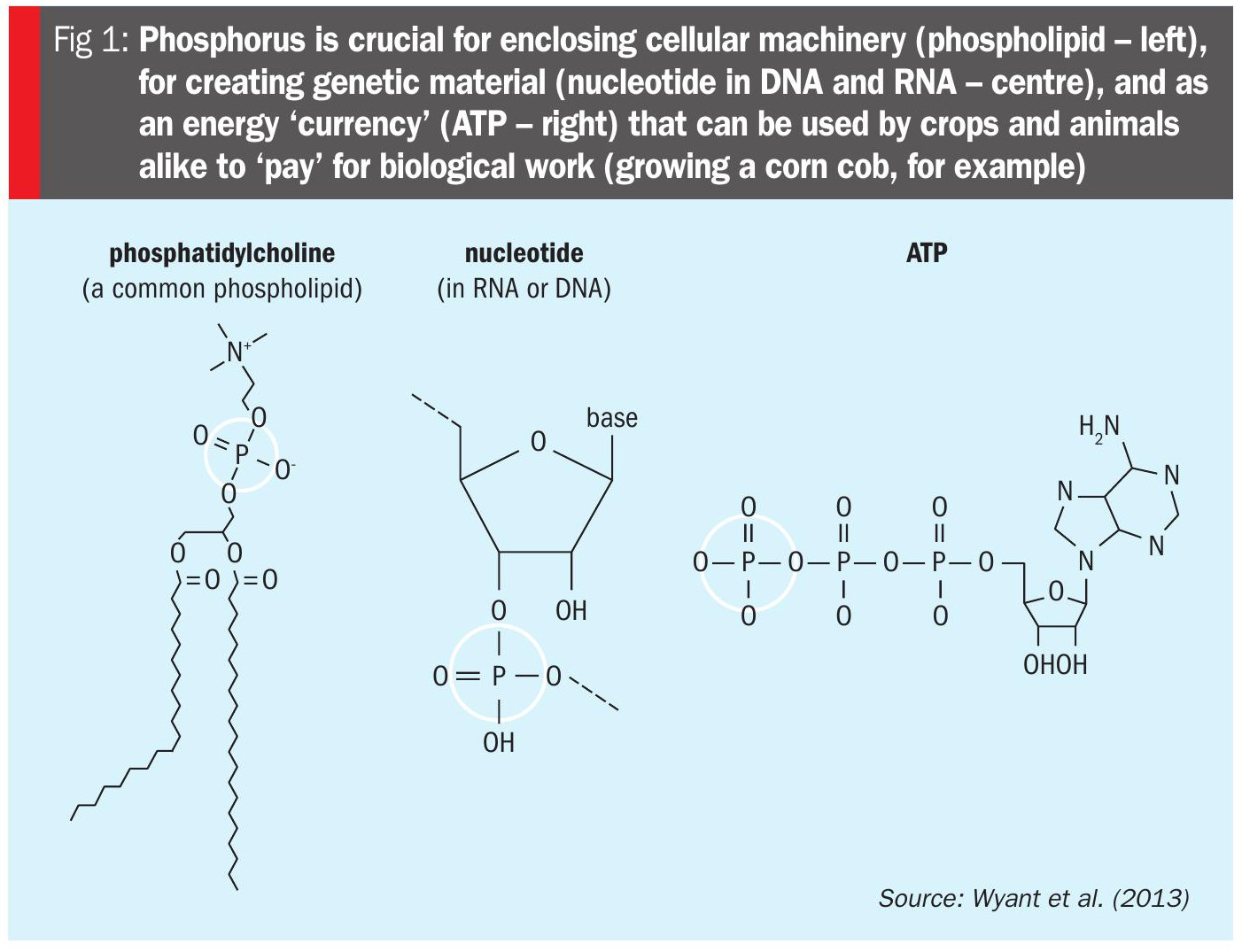

Phosphorus (P) is onethe three primary macronutrients, along with nitrogen (N) and potassium (K), that are essential for plant growth. Among its many roles, this vital element assists energy transfer within plant cells, being part of adenosine triphosphate (ATP). This can be thought of as the ‘currency’ that crops can ‘spend’ to perform biological work – such as allowing them to grow!

Phosphorus is also embedded within our genetic structure (DNA and RNA) and via membrane formation helps to enclose cellular machinery (Figure 1). At a more directly observable level, phosphorus contributes to root development and establishment, ensuring crops can access water and other nutrients efficiently. Adequate phosphorus also supports flowering and fruiting, thereby improving both the yield and quality of the crop.

We often see the impact of phosphorus scarcity when crops cannot get enough supply to meet their demands. When soils are deficient in phosphorus, plants exhibit stunted growth, delayed maturity, and poor seed or fruit production. This deficiency typically results in lower yield.

Farmers will apply phosphorus-rich fertilizers (usually in phosphate form) to meet demand from their current crop, and to replenish soil stocks when phosphorus is removed from the field in the harvested crop. Balancing phosphorus inputs with removal helps maintain soil health, optimise crop performance, and safeguards ecosystems by avoiding losses to the environment.

A global nutrient

Phosphorus – as a vital nutrient for plant growth – helps drive improved yield outcomes across global agricultural. As world food demand rises and diets change, so does the need for phosphorus-based fertilizers, particularly in regions with phosphorus-deficient soils. However, while phosphorus is a commonly applied nutrient on the farm, it can only be sourced profitably in its raw form in just a few places worldwide. Phosphorus is mined from phosphorus-rich rock, with major reserves concentrated in countries such as Morocco, China, and the US. This uneven distribution raises concerns about long-term availability, the resilience of supply chains, and exposure to geopolitical risks.

To meet future agricultural needs for phosphorus, and do so sustainably, vital innovations are needed for improving the use efficiency of P by crops – with more phosphorus being used by the crop to generate yield relative to the amount of phosphate fertilizer applied. A step change in use efficiency is a critical necessity for numerous reasons. These include better resource stewardship, greater environmental protection and last – but definitely not least! – more profitable farm economics. Sustainable intensification (getting more crops using fewer inputs from the same land area) will also be key. In that context, this article sets out the history of phosphorus fertilizers, using this as a springboard to explore avenues for future innovation.

History of phosphorus fertilizers

The emergence and development of phosphorus fertilizers is full of stories of innovation. Farmers down the ages have applied manures and composts to fields to support higher crop yields and long-term soil fertility. Throughout history, fields that were not receiving these inputs often showed yield declines and sometimes were abandoned just a few years after first planting due to poor productivity. While farmers were not exactly sure what was in the manure, in terms of understanding its chemistry, the notable phosphorus concentration in the materials they were applying was playing a vital role in keeping their fields productive.

The next major innovation came with understanding how to concentrate sources of phosphorus into a form that could apply more nutrients per tonne of applied product. In the late 18th and early 19th centuries, this led farmers to use animal bones – rich in calcium phosphate – as a soil amendment. There was a realisation that the phosphorus-rich bones and teeth could be ground up and used as a concentrated fertilizer input – bone meal. Consequently, by the 1840s, bone meal was being sold commercially across Europe and North America. However, as one might imagine, its availability as a source was not sustainable relative to the demand from farmers. After all, there are only so many bones to go around! In fact, so strong was the demand for bone meal that graveyards and catacombs ended up being pillaged to meet the demand for phosphorus.

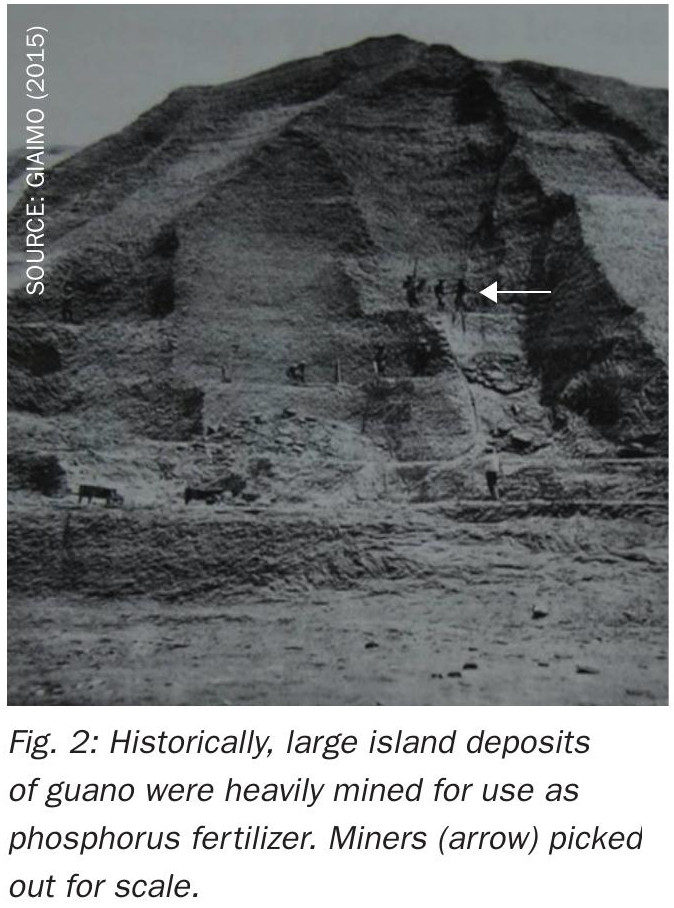

Another innovation in phosphorus fertilizer came when suppliers globally began mining and exporting guano (seabird manure deposits) from islands in warm, dry parts of the world. Such islands, over time, had accumulated many metres worth of dried, phosphorus-rich guano. These deposits were extracted, packed on ships, and sent to farmers around the world as a miracle plant food (Figure 2).

Modern phosphorus fertilizers

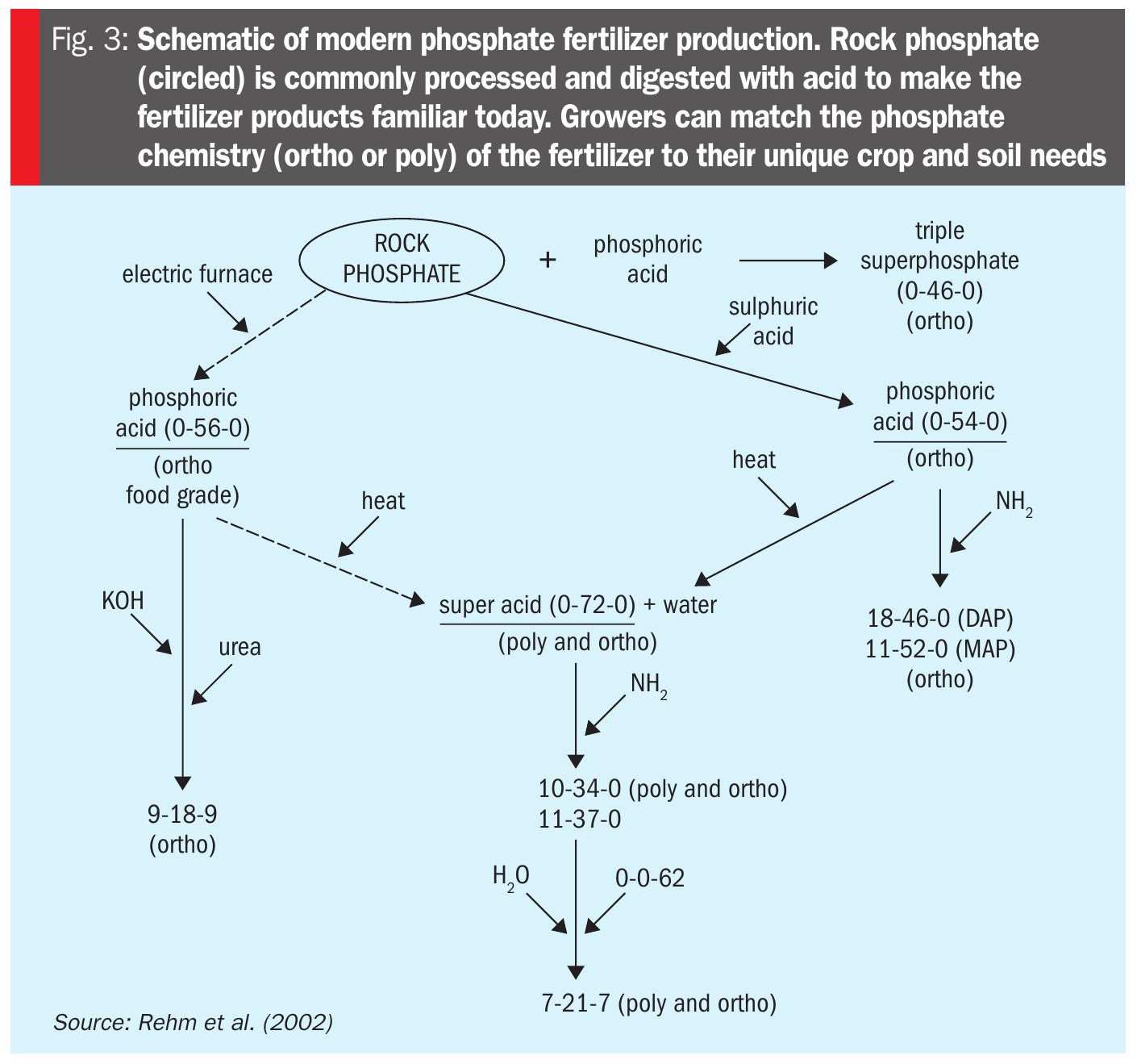

Modern phosphorus fertilizers eventually arrived in the 20th century with the mining and processing of highly concentrated phosphate rock.

The big breakthrough that enabled this came earlier, when it was discovered that reacting bones and fossils (coprolites) with sulphuric acid concentrated the phosphorus present into a much more soluble and plant available form. This made phosphorus fertilizer applications more efficient in terms of crop uptake. Shortly afterwards, in 1849, John Bennet Lawes and Joseph Henry Gilbert in England patented a process for producing ‘superphosphate’ from phosphate rock on an industrial scale. This innovation dramatically boosted phosphorus availability to plants and helped launch the modern fertilizer industry.

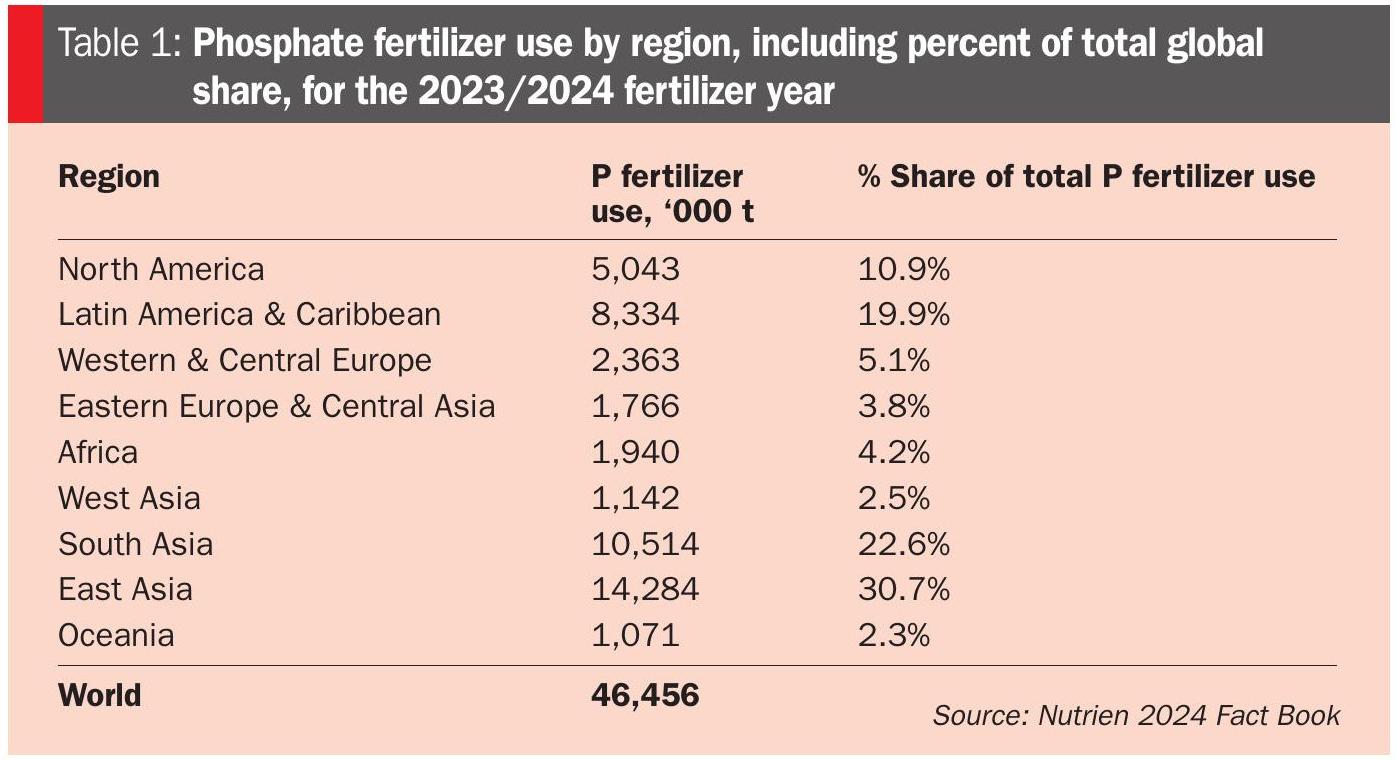

Fast forward into the 1940s, and the modern phosphate industry, as we know it today, begins with the introduction of granular monoammonium and diammonium phosphate (MAP and DAP) along with liquid fertilizers (phosphoric acid and ammonium polyphosphate), among others. Today, phosphate fertilizers are produced at large scale as widely traded commodities used by growers around the world (Table 1). We have come a long way from the old days of robbed bones and guano islands in just a short amount of time.

Why phosphorus fertilizer innovation matters

As already stated, phosphorus ranks among the essential macronutrients driving plant development, underpinning critical processes like photosynthesis, energy transfer, and root formation. Phosphorus fertilizers support robust crop yields and play a direct role in food security. However, while we have made considerable progress in how we produce and apply phosphorus-rich fertilizers, we also have the runway to develop new innovations in the future.

The fertilizer industry, by developing alternative phosphorus sources and new formulations, can reduce its exposure to supply chain shocks and safeguard agricultural resilience worldwide (Figure 4). Moreover, advances in fertilizer formulations and technology can also boost phosphorus use efficiency on farms, helping farmers grow more with fewer inputs, as was seen with previous phosphorus fertilizer innovations.

Below is a list of some opportunities across the supply chain that are likely to push innovation in the phosphorus fertilizer industry (Figure 5).

Opportunities for phosphate fertilizer suppliers

Modern phosphate mining and production technologies now enable the production of the same high quality finished products from lower quality phosphate rock (e.g., using mined ore containing less phosphorus content per mined tonne). Such innovations can reduce the need for mine expansion by extending the mine life of existing properties. The option to turn phosphogypsum (PG) waste into a calcium-rich soil amendment is another opportunity for phosphate producers. While this would avoid the costly storage of PG in managed stacks, in the near term, such a shift would depend on regulatory review and approval in jurisdictions such as the US. Finally, some new market entrants and incumbents are starting to produce fertilizers by recycling secondary nutrient sources, including concentrated food industry waste and liquids, as well as solids from wastewater treatment plants.

Opportunities for agricultural input retailers

One promising retail-level innovation is the custom blending of fertilizer components to address the unique nutrient management challenges of both soils and crops. Common components can now be blended at scale – including phosphorus-rich fertilizers – to best match the soil deficiencies of a particular field and address the nutrient uptake patterns of individual crops. Additionally, agricultural input retailers are in a unique position to add new functional components to blends. This involves adding novel compounds (humic acids, micronutrient coatings, etc.) that bring with them extra properties that differ from the foundational nutrient properties of fertilizers. Overall, this is an area of innovation that is teeming with activity at global scale, as retailers work to match soil and crop data to traditional fertilizers modified with help from the ‘new ingredient’ partners that have emerged in recent decades.

Opportunities for growers

Growers as the end buyer have a key role to play in the innovation pipeline. After all, they are ultimately the people who recognise and create the demand for inventions, based on their individual field needs, market conditions, or regulatory pressures. Growers, for example, have an opportunity to use soil and satellite data on farms to create prescription fertilizer application maps (e.g., variable rate) and generate custom blends for each field (mixes of urea, monoammonium phosphate, and muriate of potash, for example) as dictated by the unique characteristics of the field. Capturing innovative technologies and datasets allows growers to spend more judiciously on fertilizer inputs while optimising yield outcomes. Additionally, growers should benefit in future from an increasing ability to directly manage their fertilizer rates, the timing of the application, blend composition, and fertilizer placement (4Rs nutrient management) – changes which will also benefit phosphorus use efficiency and reduce off-farm nutrient losses.

Shaping tomorrow’s supply chains

Humanity has long used phosphorus-rich materials to bolster crop yields and soil fertility. Yet modern phosphate fertilizer technology has undergone an exciting journey of rapid transformation in a relatively short period of time. It was not that long ago that we were mining guano islands as an agricultural source of phosphorus, and here we are now taking phosphate rock ore and turning it into high analysis phosphate fertilizers that are traded and used across the globe as valued commodities. One thing is certain, there will be many innovation story lines emerging in the phosphorus supply chain over the next few years that will be exciting to watch. Because of that, the industry should expect that a new frontier for this nutrient is just around the corner.

References