Nitrogen+Syngas 361 Sept-Oct 2019

7 August 2025

Problem No. 56: Oil fouling from ammonia plant

One of the most important control parameters in urea plant operation is the synthesis pressure and a sharp increase of this pressure is very dangerous for the urea plant. One cause for an increase of the synthesis pressure is oil contamination in the urea process which causes many abnormal variations in many sections of the plant. This problem can be recognised by taking a sample from the ammonia feed and observing the colour change of the urea product. These samples and observations can prevent much confusion in determining the cause of the problem.

Ahmad Hussain of Engro Fertilizers in Pakistan starts this round table discussion: Since last month, the ammonia we receive at battery limits has had a high oil content due to a leaking low pressure stage oil seal of the refrigeration compressor in the ammonia plant. Our machinery team is dealing with this problem. Meanwhile can anyone suggest any filters that can be used in the urea plant to remove the oil from the ammonia that is received at battery limits?

Tajinderpal Singh Bajwa of Canadian Fertilizers Industries in Canada faces a similar situation: We are currently facing the same problem, which is limiting us on total throughput and resulting in operating the plant below the nameplate capacity.

We know that the oil contamination in the ammonia feedstock is coming from an ammonia plant compressor seal leak. Is there a better oil sealing technology for the centrifugal compressor? Are any mechanical separation systems available upstream of the ammonia surge drum before the ammonia passes through the booster pumps and into the suction of the HP ammonia pumps?

Bhupen Mehta of IFFCO Kalol in India joins the discussion: Oil ingress in the ammonia product is mainly from the low pressure case oil seal leakage of the ammonia refrigeration compressor. It is better to have a dry gas seal for the ammonia refrigeration compressor. However, for oil seals: 1) the buffer gas pressure of the low pressure case should be

monitored (>0.07 to 0.2 kg/cm2g higher than suction pressure) and 2) the gravity drain from the trap may be limiting due to low suction side temperature, a level control valve in place of the trap can be checked to avoid oil hold-up in the trap due to malfunctioning.

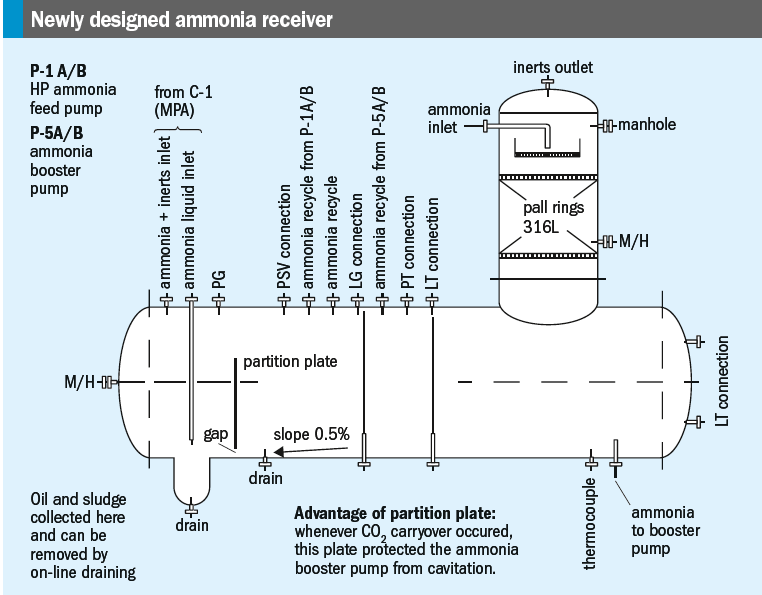

Mark Brouwer of UreaKnowHow.com in the Netherlands replies to two questions from Taj: An upgrade to dry gas seals will definitely solve this issue. On the other hand these are more sensitive during operation, especially for water ingress. The dry gas seals skid should be carefully designed for start-up conditions. The temperature of the seal gas should be kept above the dew point. Oil separation takes place in the ammonia receiver, and intermediate suction drums.

Any respectable licensor (since 1960s) equips the suction drums and ammonia receiver with a permanent drain via the orifice to divert the ammonia contaminated with oil to the last drum and further to storage. Also, any low point of piping from the compressor discharge lines should be equipped with spring loaded valves so that operators are able to drain the ammonia during normal operation.

Prem Baboo of Dangote Fertilizers in Nigeria shares his valuable insights: The oil can be separated in the ammonia receiver (see diagram). In a newly built plant a partition plate was provided to protect the carry-over CO2/carbamate from the MP absorber. A pot was also provided at the end of the receiver bottom for collecting the oil /sludge which can be drained while the plant is running. This modification can also be made to an old ammonia receiver.

Amir Hosein Tafazol of Shiraz Petrochemical Complex in Iran shares his experience: For several years we have been using a PALL coreless filter for the ammonia line in the urea plant, upstream of the ammonia HP pumps to prevent oil and catalyst powder from entering the urea plant. Previously we had a problem of clogging of the liquid dividers in the HP stripper. After installing this device we haven’t had any problems.