Nitrogen+Syngas

7 August 2025

Problem No. 37: Faulty reactor pressure transmitter

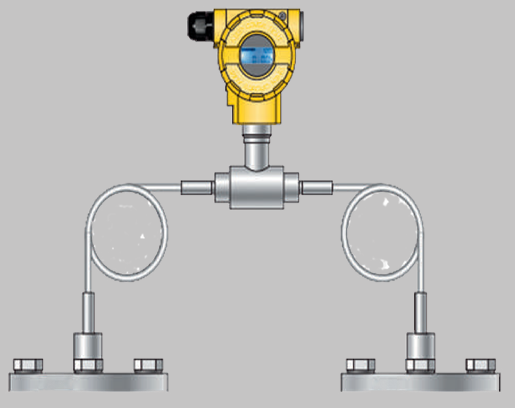

Pressure transmitters have become essential parts of virtually all urea plants. Pressure measurement undoubtedly forms an important measurement in industrial process measurement and control. Pressure transmitters convert an applied pressure into an electrical signal, which is then transmitted to a device such as a computer, programmable logic controller, recorder, or digital meter to analyse the electrical signal and utilise it to display, record, or modify the device’s pressure. A schematic of a pressure transmitter is shown in the picture below.

Mr Ab Samad Noraini from Petronas Fertilizer, Malaysia initiates a discussion of a familiar problem in urea plants: Our plant uses Saipem technology and we have experienced frequent faults with our reactor pressure transmitter. Because of this we often need to by-pass the protection of the trip logic of urea reactor.

Currently we are using a capillary type pressure transmitter. Does anyone else have similar problems and experiences that they can share and advise on modifications to solve the issue?

Mr Waheed Ahmad from FFC, Pakistan is first to respond: Different options are available to eliminate this problem. Please specify the position of the transmitter. How many times have you experienced tripping or failures?

Mr Girish Prakash from Tata chemicals Ltd, India joins the discussion: Reactor pressure transmitters are prone to failures but with certain precautions you can ensure a longer life. One of the easiest methods is to ensure proper working of tracings. In no case should they be in an isolated condition once start-up is under progress or the reactor is under draining.

Mr SK Gupta of IFFCO, India shares his experience: The reactor pressure transmitter installed in the CO2 line, just after the control valve in the CO2 line near the reactor, is always giving us problems. You can install the transmitters in a horizontal position by rotating the spool piece between the control valve and the reactor. This will reduce the frequency of failure.

Mr Mark Brouwer of UreaKnowHow.com, The Netherlands provides some more suggestions:

Other options to improve the reliability are:

- measure the reactor pressure in the ammonia line

- when measuring in a carbamate line, use tantalum as membrane material

Mr Gopala Krishna of Safco, Saudi Arabia, provides more information: You mentioned you are a using a capillary type transmitter but the most reliable transmitter is the pad type. Also when the transmitter is faulty its sensor element should show the minimum value; this measure can be taken by instrument people. Secondly, the high pressure reactor reflects the high pressure of the compressor, hence the reactor high pressure trip can be bypassed or reactor pressure influences more or less MV-01 (separator pressure) so the reactor high pressure trip can be shifted to the separator pressure trip.

Recently an accurate and reliable pad type pressure measurement has been developed, which is successfully in operation since September 2011 and is able to measure the pressure even in high pressure carbamate gas lines.

MrJavant Panvelkar of Zuari industries limited, India shares his experiences: We have the impulse tubing type pressure transmitter on the ammonia feed line and it is working fine. The only time it has gone wrong is during shutdowns when the reactor is in a boxed up condition, due to carbamate entering the impulse lines. This is easily cleared by flushing the lines. As previously mentioned, new technologies are available, but I feel the problem with the pad type is that if it fails it is not possible to to replace it online. Two pads probably will have to be used? We flush the transmitter lines once a month.

Mark provides more information: In stripping plants it is an advantage to measure the synthesis pressure as close as possible to the safety valves, i.e. in the carbamate gas line.

This new development makes that possible without risks of crystallisation and corrosion.

These special pad type pressure measurements are in operation since Sept 2011 without any problem.

Mr Kashif Naseem of SABIC, Saudi Arabia gives his suggestions: The most suitable place for this pressure transmitter is the ammonia feed line to the reactor. You can use a double pressure transmitter diaphragm type and make both at different pressure frequency. So make the trip point when both will appear.

Mr Ismail Ahmad of Ruwais Fertilizer, United Arab Emirates shares his experiences: We are using Stamicarbon technology and face a similar problem. However, we are going to replace the existing unit with a remote seal (extended diaphragm) type. It will be installed directly to the pipe, and the sensing diaphragm will be at same level as the piping surface, thus preventing the crystallization problem. Based on feedback from other plants using similar technology, the problem is resolved by using this transmitter. We will be installing the new transmitter this coming September.

Mark provides more information: Badotherm has successfully developed a safe and reliable membrane type of pressure and level measurement suitable for all urea process technologies. On stream times of already nearly two years have been achieved without any issues. This means significant costs can be avoided and additional profits can be gained with the innovative Badotherm diaphragm seals mounted to transmitters.

The Badotherm extended type diaphragm seal with all wetted parts in zirconium.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |