Nitrogen+Syngas

30 September 2018

Problem No. 50: Low vacuum pressure in the second-stage evaporator

Most urea plants operate a two-stage evaporator section. Both stages operate under vacuum pressure conditions and both pressures and temperatures are critical to achieve the right urea product quality. It is not always easy to determine the exact cause of non-optimum values for certain process parameters like, for example, low vacuum pressure in the second stage evaporator. Many factors can influence this vacuum pressure as discussed below.

Mohit Bayer of CFCL Kota in India starts the discussion: In our plant we are experiencing a problem with the vacuum pressure in the final concentrator which is very low (it is now 105 mm Hg, whereas before it was 60 mm Hg). We have done all types of flushing. We have checked that air is not being sucked in through the flange connections. We have insured that the condensate outlet lines of surface condensers are not choked. The instrumentation is also okay. The urea sample moisture content is 0.56 wt-% which is not very high compared to before. The plant is TEC ACES technology running on two trains with a common prilling tower. The problem is in one train only.

- Are there any other parameters that can show that the vacuum pressure is really low?

- To what extent will this very low vacuum pressure affect the product quality?

- How can we insure that the final concentrator heat exchanger tubes are not leaking?

- What will happen to the steam consumption of the heater of the final concentrator when the vacuum pressure is low: will it increase or decrease?

The actual cause is still unknown. We have performed a lot of flushing and tried to clear the path of vapour. We have also performed a lot of polymer washing, and insured that the vacuum is not broken anywhere.

Kashif Naseem asks for some further clarifications and provides some valuable suggestions: What are the evaporator parameters? Check that the flushing valves are fully closed. Purge your surface condensers. Flush the bottom bottles of the surface condensers and check the ejectors (maybe the downstream line is choked).

Mohit replies: We have checked all of the things you suggest and all are clear. The evaporator parameters are as follows: shell side steam pressure 2.8-3 kg/cm2g; tube-side inlet urea solution temperature 131°C; tube-side outlet urea solution temperature 136°C; tube-side pressure 50 mm Hg; flow of urea solution 60-65 m3/h; temperature of urea outlet solution is controlled by steam pressure; urea inlet to this evaporator comes from the first evaporator that is operating on 150 mm Hg vacuum, its vacuum is taken by an ejector that is in the vapour outlet of a surface condenser (say No. 3), uncondensed vapour of this condenser No.3 goes to surface condenser No. 1 (condenser for first stage evaporator) whose vacuum is taken by an ejector in its downstream line; surface condenser No. 1 operates at 150 mm Hg and No. 3 at 50 mm Hg, these two ejectors are in series; the vacuum of the first evaporator is okay.

Majid Mohammadian of OCI Nitrogen in the Netherlands shares his experiences: Vacuum in concentrators is mostly the result of cooling in the condensers, performance of the ejectors and the concentration and temperature of the urea solution. Sometimes partial crystallisation in the condensers may occur leading to a bad vacuum pressure. If the urea solution concentration is correct my suggestions are as follows: First raise the condenser temperature in the cooling water return line to about 45 to 50°C for a short time and check that there is no partial crystallisation in the condenser. Secondly check the ejector internal and its performance.

Mohit replies: We have already done what you suggest many times, we call it condenser hot flushing, but it has not helped.

Muhammad Farooq of SABIC/SAFCO in Saudi Arabia offer his suggestions: As the moisture content is quite high, it looks to me like the final concentrator may be overloaded. I would suggest checking the following: urea solution concentration in the urea solution tank downstream of the low pressure decomposer/ flash tank compare it with the design value in the mass balance (percentages of ammonia and water are important); urea solution concentration after the first evaporator/concentrator (percentage of ammonia in wt-ppm); condition of the final ejector line-up to the condenser polymer deposition will hamper the vapour path to the surface condenser.

Does the vacuum pressure change when you carry out flushing of the final ejector line up to the condenser for 1-2 hours with hot media? Finally check physically/internally the nozzle of the final ejector of the final concentrator.

Mohit replies: The vacuum pressure in the first concentrator is within the normal range, so there is no chance of more ammonia and water in the low pressure decomposer outlet. The conditions in the back end are also the same as before. We have also done polymer flushing and because it may choke the vapour path it is done with the help of molten urea, but it makes no difference. As far as the ejector is concerned, there is no provision for flushing the ejector of the final concentrator.

Siddharth from Tata Chemicals in India shares his experience: I would like to share an improvement we made to our urea plant before shutdown of the plant during the annual turnaround of 2012. Before the turnaround, we were faced with the problem of huge deposition of polymer in the first and second stage separators of the vacuum sections. In view of this problem we started dome flushing of both separators with urea melt on a daily basis for 15 days before doing the shutdown. Even after shutdown of the plant we continued this flushing for more than 8 hours, recirculating the melt through the recovery pump. The result was splendid as much less deposition of polymer was observed in the separators and we have saved a lot of water and reduced the amount of disposal of polymer and manual work, which had been necessary earlier. In my opinion the circulation of urea melt for separator dome flushing is an important and useful activity.

Sam QR from India joins the discussion: Do you have a demister in the vapour outlet of the second stage evaporator and if so where is the pressure measurement taken, upstream or downstream? Have a routine for boiling out the second stage evaporator with 72 wt-% urea solution (once every two months). Be careful not to contaminate the evaporator condensate with urea solution, which will affect the hydrolyser. Based on the volume of the second stage evaporator/inlet solution flow rate, determine the time required to fill the second evaporator and fill the evaporator with urea solution. This will greatly help in removing poly-urea.

Evgeniy Shishkin of Koch Industries in the United States asks for further information: We are experiencing similar issues. Do you have any more information on what you mean by poly-urea and the procedure for flushing it out with urea solution?

Mark Brouwer of UreaKnowHow.com replies: Poly-urea refers to polymers of urea like biuret, triuret etc. These are formed quite easily in the second stage evaporator and dissolve easily in urea melt. Nowadays, many urea plants apply a flush system with urea melt (from discharge urea melt pump) on the second stage separator. It is of course important that these small flush lines can be flushed out when they are not in use.

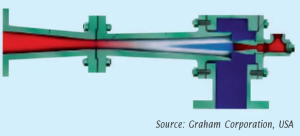

Aslam Muhammad of Fauji Fertilizer Company Limited in Pakistan provides another suggestion: Please check the ejector downstream nozzles for choking or dislodgement.

Zeeshan Shoaib of Fauji Fertilizer Company Limited in Pakistan shares his experience: I will add just two more suggestions as per our own experience as we have faced similar problems. Map the temperature of the ejector and condensers from outside and observe any change. It will help to rule out the health of the ejector and condenser. Measure the cooling water flow to the vacuum section and the condensers. Back flush the condensers from the cooling water side online after by-passing the feed of vacuum section at reduced plant load. We have implemented these ideas and the poor vacuum pressure problem diminished.

Prem Baboo of National Fertilizers Ltd in India joins the discussion: The problem of second stage vacuum pressure might be due to a leakage in the vacuum system i.e. flanges of heat exchangers, condenser sight glasses, all equipment flanges. Flushing of the condensers is a temporary phenomenon, after flushing it can be improved further. There is relationship between the vacuum pressure and the separator outlet temperature. Various parameters are related to vacuum. For example if vacuum pressure is pulled out then the temperature will come down and the steam requirement increases. The moisture content in the urea product is also affected by weather conditions. The steam pressure can be increased to improve the vacuum ejectors. If there is sufficient margin in the first stage vacuum then it can be improved subject to the outlet temperature of urea and according to the concentration and temperature graph. If the outlet temperature of the first vacuum is more than 120°C then it can be increased to 225-240 mm Hg so that the load on the second vacuum is shifted to the first vacuum. The detection of leakages in the vacuum system can be checked. The procedure is tricky: two or three persons are required to check for leaks, break the vacuum pressure and all ejectors steam valve should be closed, slowly closing the condenser cooling water outlet valve. In so doing, the system pressure will increase to more than 750 mm Hg and any vapours will leak out. Observe and note down the leakage points and open the cooling water valve immediately.