Nitrogen+Syngas

30 June 2017

Problem No. 42: Coated urea fertilizers

Coating urea prills (granules) with a water-insoluble, semi-permeable, or impermeable (with pores) material delays the release of nitrogen from the urea. Urea is highly soluble in water, but the solubility of coated urea is dependent on the coating material, its thickness, and the coverage and uniformity of the coating on the granule. As the urea is gradually released from the coated granule, it is exposed to the same chemical and biological processes as non-coated urea. Coated urea provides a safer and more efficient form of urea by:

- improving stability in fertilizer blends.

- safeguarding against nitrogen losses through volatilization and degradation;

- slowing down leaching due to its slow-release characteristics;

Amirhossein Hadian from Khorasan Petrochemical company, Iran starts the roundtable discussion: I am researching coated urea fertilizers – controlled release fertilizers consisting of urea prills, coated with less-soluble chemicals such as sulphur, polymers, etc. Does anyone have any suggestions for coating urea prills to slow down dissolution rates when used on farms?

Luis Nogue from Bunge, Argentina shares his information: There is a company called NAQ Global who specialise in anti-caking and anti-dusting agents. They are present in Asia, Middle East, North America you can see more info on their website.

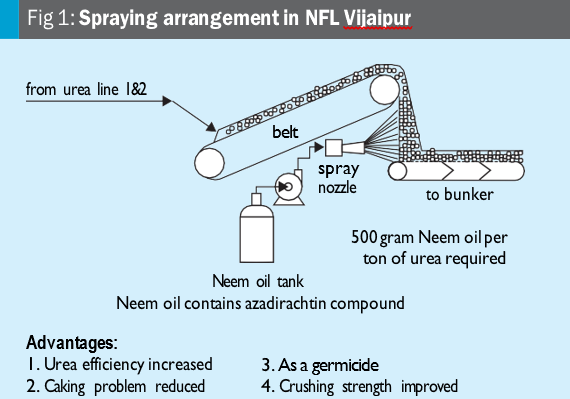

Prem Baboo from National Fertilizers Ltd, India provides more information: We are also producing neem (azadirachtin) coated urea. It is well known that neem has great potential for increasing the efficiency of urea. Indian agricultural scientists were the first in the world to establish neem as a nitrogen regulator. National Fertilzers Ltd., Vijaipur started using it in October 2004.

Neem-coated urea has the following advantages:

- Neem cake when applied along with urea retards the nitrification rate for about two weeks and thus more nitrogen remains available as ammonium for a long period.

- 350 ppm of neem oil content is being maintain at NFL Vijaipur as per the guidelines under section 20(a) FCO.

- Useful as a germicide to help crop decaying.

- Neem product namely neem oil, cake, neem bitters concentrate and neem oil were identified as good nitrification inhibitors.

Development of process for coating urea prills

NFL has carried out development work for the coating of urea in fertilizer plants, where plant conditions require a new approach to use neem cake or neem bitters for urea coating. The work was divided in two parts: (1) developing a suitable neem product which could easily be sprayed on urea prills in the final product stage and (2) development of a suitable arrangement for spraying neem product after leaving the prilling tower.

Amirhossein Hadian from Khorasan Petrochemical company, Iran asks for more information: We are interested in neem products. How much dust reduction can we expected by spraying neem oil? We currently spray Uresoft-150 after the urea fluidised bed, can we substitute it with neem oil?

Prem Baboo from National Fertilizers Ltd, India provides more information: Neem coating is being carried out in the final stage, immediately loaded in bags. When farmers apply urea on the farm, the rats and rabbits vacate the field. It is also a germicide. Neem coating definitely reduces dust generation. You can switch from Uresoft-150 to neem. Crushing strength is also improved by neem e.g. before coating 650 gm/prill and after neem coated 670 gm/ prill. You can apply neem after the urea fluidised bed.

We started using neem coating in 2004 as a trial run, nowadays there is increasing demand from farmers. At present, it represents about 40% of total production by National Fertilizers Ltd. Fertilizer companies, including Tata Chemicals & Fertilizers, Babrala and Indo Gulf Fertilisers, Jagdishpur also produce neem-coated urea.

Vinay Gandhi from GSFCL, India provides more information: GSFCL, Vadodara, Gujarat, India has also started production of neem coated urea prills. The response from farmers is overwhelming. George Van Bommel from Energy Consultancy UREA, The Netherlands shares new information: There are at least 10 suppliers of various urea agents, which all claim various improvements of properties. The question is: Which property do you want to improve, and how much do you want to pay for it per ton of prill or granule

Read chapter 16 of the Fertilizer Manual, than make your choice of the following products (suppliers) in no specific order (others may also be available):

- NovoFlow (Novochem) • Flotigam (Clariant)

- UreaSoft (Kao) • UltraCoat (SSCI)

- UreFlo (Filtra) • UreCoat (Neelam)

- Galoryl (Arrmaz) • Fertibon products

- AC Fert 100 (Kephas) • FA1665 (Forbon)

Amirhossein Hadian from Khorasan Petrochemical company, Iran raises new questions: When neem oil is sprayed onto urea prills, do the coated prills have a special odour and does it cause problems for storage and workers in bagging?

Prem Baboo replies: Neem coated urea does have a bitter smell but it is not pungent, and poses no problem for any workers, nor harm to health. In India about 11 plants are producing neem coated urea and there have been no problems with loading and handling. Mark Brouwer from UreaKnowHow.com, The Netherlands provides supplementary information: Neem also acts as an anti-caking agent.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |