Nitrogen+Syngas

30 April 2017

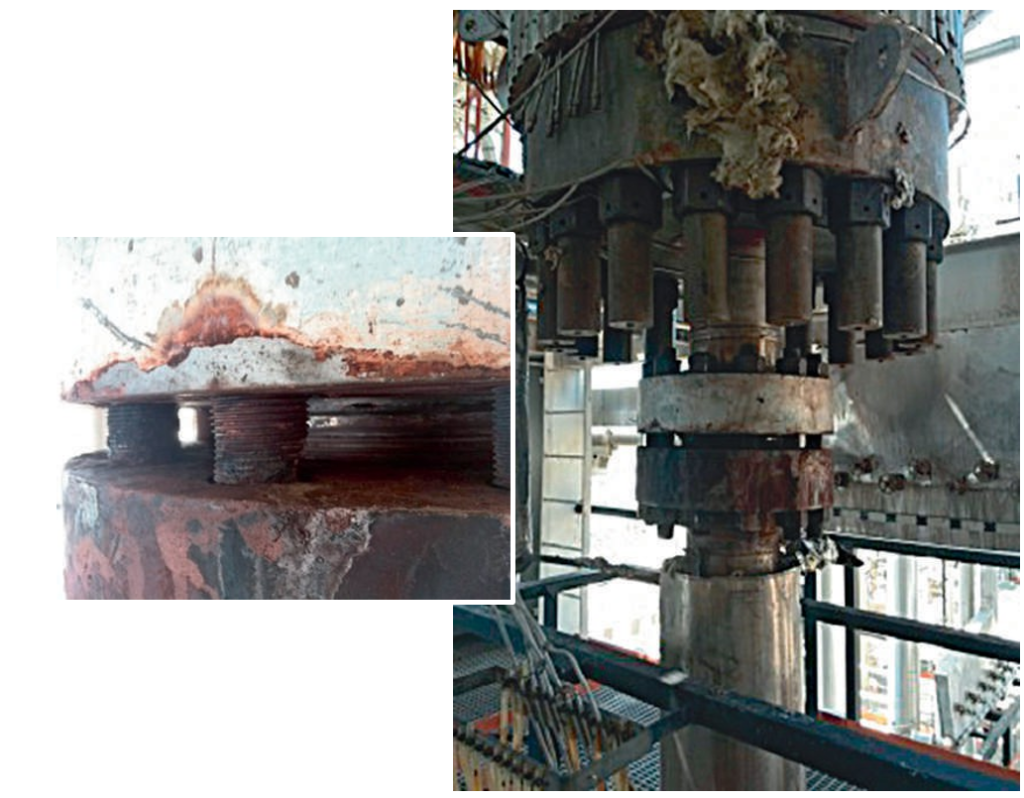

Problem No. 41: Leakage of a high pressure flange connection

Among the many problems that threaten the daily operation of a urea plant, fluid leakage is perhaps the most common, especially the leaking of high pressure flanges in the urea synthesis section. A high-velocity jet emerging from a flange due to a failed gasket, a pinhole in an elbow, corroded threads of a level transmitter, etc., are familiar scenes that the maintenance crew encounters and must rectify.

Mark Brouwer from UreaKnowHow.com, The Netherlands replies: There is only one course of action – stop the plant and replace the lens ring and bolts.

Prem Baboo from National Fertilizers Ltd, India offers his advice: It is not possible to replace the corroded bolts while the plant is running, it is very risky. It may be possible to stop the leak by clamping and applying a cold weld. Mechanical problems in early satellites have sometimes been attributed to cold welding. Our stripper bottom manhole cover flange has had leakages on many occasions and they were stopped by applying cold weld material. Furmanite is the worldwide innovator and leader in comprehensive on-site and on-line plant and pipeline maintenance. The Furmanite seal has been invaluable in keeping our unit up and running. please don’t take any risk.

Isa Norozi from Khorasan Petrochemical Company, Iran provides more information: For your information, the very small leakage happened inside the insulation sheet but there is no longer any leakage from the flange. As you see in the pictures, one of the bolts was severely corroded and the others were slightly corroded. Can we continue in this way or do we need to replace them with new ones?

Mark Brouwer from UreaKnowHow.com, The Netherlands shares more experience on this topic: The fact that the leak has stopped does not mean the problem has been solved! On the contrary, carbamate will be present in the crevices between the lens ring and flange and as oxygen will be depleted, active corrosion will start. Only time is needed to cause a potential deadly failure. Please note that active corrosion occurs in stainless steel materials at rates of > 50 mm/y. The application of cold clamps and/or Furmanite on carbamate leakages is very risky for the same reason. One can never ensure that there will be no crevices where carbamate can be present causing active corrosion to stainless steel parts. I repeat, there is only one course of action recommended: Stop the plant and repair the leak.

Yudhistira Perdana Putra from PT Pupuk Kaltim, Indonesia shares his advice: The leakage may have stopped due to solidification of the urea carbamate solution. It may seem to have stopped but corrosion may still be occurring at the flange face of the HPCC. It is much too risky to keep the plant running.

Isa Norozi from Khorasan Petrochemical Company, Iran provides more information: Now that the leakage has stopped we have seen small bubbles of gas escaping from two points of the flange, but not continuously. The insulation of the flange is open and the leakage is under visual check by operators and inspection groups and hasn’t shown any sign of change up to now.

Mauricio Medici from M&M-CT Company, Argentina also shares his experiences: I agree with Mark and other colleagues here, leakage of HP equipment or lines, are always under discussion. Nobody wants to shut down the plant, especially plant managers, but although the leak appears to have stopped, corrosion may continue, as you mention this gas leak indicates that crevice corrosion in the lens rings/flanges is occurring (oxygen depletion), on the other hand carbon steel bolts are in great danger, and it’s difficult to check the back side or the inner area of nuts.

The recommendation of performing a shut down soon is the best option, to avoid injuries and major loss. Try to keep the area clean of solid carbamate. Never replace bolts while the plant is running!

M Hassan from a fertilizer plant in Pakistan provides more advice: Keep the area clean on a daily basis. Apply steam at the location of the leakage so that build of carbamate does not occur and you are not blinded. Maybe try slightly tightening if the leakage rises may help.

Don’t replace the bolts while the plant is running. The condition of the bolts does not look too bad from the pictures (maybe close up it is a different story.

Never go for cold box up on this service and pressure. Whoever did it was very lucky to avoid a disaster.

Isa Norozi from Khorasan Petrochemical Company, Iran provides an update: Thank you for all your recommendations. We had a short shut down because of a gas compressor failure in the ammonia plant. During this time we have changed the bolts. Only one bolt was corroded on its outer face.

Syed Ali Salman Bokhari from Pak-American Fertilizers, Pakistan also shares his opinion: I must say “Nip it in the bud”. Although it may be a painful decision, it is better to stop the plant and take the corrective actions as per standard operating procedures. A little production loss is much better than huge man and equipment loss.

Khalid Khattak from FFC Goth Machhi, Pakistan also comments: Box up is to be avoided in HP equipment. Don’t do it.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |