Sulphur index 2024

A complete listing of all articles and news items that appeared in Sulphur magazine during 2024.

A complete listing of all articles and news items that appeared in Sulphur magazine during 2024.

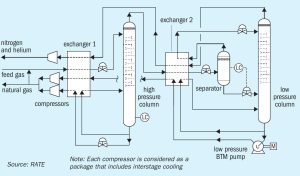

As the oil and gas industry focus on new requirements for CO2 recovery, cryogenic processes come under the spotlight. Mahin Rameshni and Stephen Santo of RATE USA discuss the importance of cryogenic processes in acid gas sweetening. Liquefied H2 S and CO2 reinjection is proposed as a cost effective alternative to large sulphur plants.

This year will be the 40th Sulphur – now Sulphur + Sulphuric Acid – Conference to be held. From its beginnings in Canada to this year’s meeting at the Hyatt Regency hotel in Barcelona, much has changed, but its mission – to be an essential annual forum for the global sulphur and acid community – remains the same.

China’s acid production continues to grow as new smelters come on-stream. But high domestic demand from phosphate production as export restrictions are lifted and a shortage of copper concentrate may limit the potential for acid exports.

Refinery sour water strippers are an often overlooked resource of low GWP ammonia. Martin A. Taylor and Charles L. Kimtantas of Bechtel Energy Technologies and Solutions, Inc. (BETS) show the results of a study on reusing an existing SWS as one of the major systems in a SWSPlus unit for the recovery of ammonia for sale. Relative cost factors will compare a complete SWSPlus unit versus reusing an existing SWS.

Representatives from across the global sulphur and sour gas community convened in Abu Dhabi from 20 to 23 May to discuss and debate the key strategic themes that are driving the industry. The Middle East Sulphur Conference (MEScon) is a premier event that brings together representatives from the entire sour gas and sulphur value chain to promote technology and innovation, lessons learned, best practices, knowledge transfer and R&D.

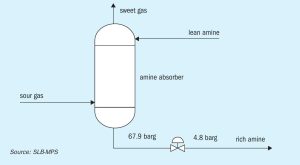

Aparna Saiju and Nishevitha U G of SLB-MPS explore the concept of energy optimisation using power recovery turbine (PRT) technology in amine sweetening units, focusing on its potential benefits, implementation strategies, and environmental implications.

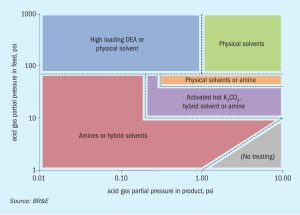

Ganank Srivastava of Bryan Research & Engineering examines ways to reduce carbon footprint in sour gas facilities.

Though production, particularly from sour gas in Alberta, has declined, Canada remains the world’s second largest exporter of sulphur.

Falling volumes of sulphur from refining and sour gas could turn Europe into a sulphur importer.