Sulphur + Sulphuric Acid 2023

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.

Ballestra, Nitricity, Solex Thermal Science and Stamicarbon showcase their state-ofthe-art equipment and technologies.

The recovery of waste heat from Aurubis’ copper smelting operation in Hamburg is already helping to reduce global carbon emissions and has the potential to provide heat for up to 20,000 homes through the district heating network in Hamburg’s HafenCity. The energy for the network comes from waste heat that Aurubis recovers from their sulphuric acid plant, using unique Alfa Laval plate heat exchanger technology.

The sulphuric acid process is virtually carbon free and, as such, it is important to consider the energy requirements of the associated industrial complex before deciding upon what form the energy should be exported from the acid plant. In this article, Stefan Braeuner, Stefan Mohsler and Anne Mohsler of Metso Outotec use case studies to exemplify the need to fully analyse the local conditions at site before a decision is taken on a specific flowsheet.

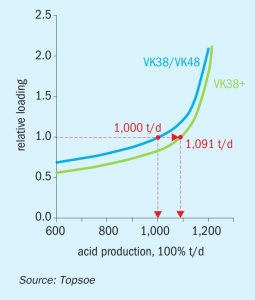

With energy prices skyrocketing, sulphuric acid plant operators face a heightened challenge to improve plant efficiency. Martin Alvarez from Topsoe discusses how the company’s new high-activity catalyst, VK38+, can help acid plants maximise energy efficiency to secure important economic benefits while simultaneously reducing their carbon footprint.

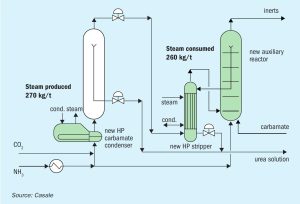

Casale reviews urea plant revamping process schemes and successful case studies for energy savings and TOYO discusses its latest revamping technologies including application of the new generation low-pressure, energy-saving ACES21-LP™ process.

Heat recovery systems at sulphuric acid plants have been providing carbon-free energy for decades now and continue to improve. There is also potential to combine the clean power generated at acid plants with hydrogen production from water electrolysis. This could provide the basis for green fertilizer production.

As all industries come under pressure to decarbonise, are there ways to reduce the carbon footprint of sulphur recovery operations?

Saipem, Stamicarbon, Toyo Engineering Corporation and KBR showcase recent projects and latest technology for urea and nitric acid plants.

A sulphuric acid plant forms critical material and energy interfaces with other plants in several different types of chemical and metallurgical complexes. Shailesh Sampat of SNC-Lavalin discusses how the acid plant design is customised to match the product mix and the energy requirements of the complex to provide the optimum solution for energy and material requirements.