Sulphur: the fourth crop nutrient

Sulphur is becoming an increasingly important crop nutrient – due to a combination of lower sulphur emissions, the increasing prevalence of high-analysis fertilizers and higher cropping intensity.

Sulphur is becoming an increasingly important crop nutrient – due to a combination of lower sulphur emissions, the increasing prevalence of high-analysis fertilizers and higher cropping intensity.

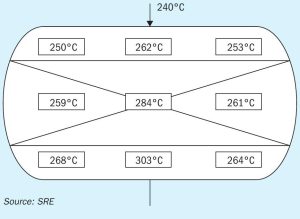

With the ongoing changes in gas field and refinery feedstock compositions, many sulphur recovery units around the world are facing turndown scenarios to such an extent that it is difficult to meet stringent environmental regulations. Equipment and instrumentation behave differently under turndown conditions, and not always in ways that are desirable. Start-ups and shutdowns can place demands on the equipment that are more severe than years of normal operation. In this article, Optimized Gas Treating, Sulfur Recovery Engineering and Comprimo share some of their learnings and experiences of these scenarios.

We highlight recent innovations in sulphuric acid plant design and construction. NORAM and CPPE are offering a new hybrid sulphuric acid process. KVT, meanwhile, has upgraded its wet sulphuric acid technology to reduce capex, opex and emissions. Improved methods of construction and new materials from Koch Knight are also helping to optimise acid tower design

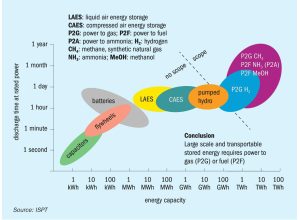

Imagine an industry that only uses carbon-free fuels and does not have any carbon footprint. Assume this is feasible within a decade. Now wouldn’t that be an ambition worth pursuing? Duiker believes this is achievable. A. Lanser provides Duiker’s view on how its SCO technology can act as an enhancer for reducing industrial carbon footprint.

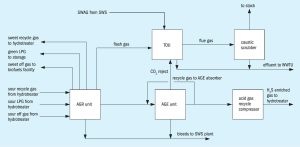

R. Kranenburg of Duiker discusses the latest applications of SCO units in refineries and petrochemical complexes. The SCO unit is typically integrated in the sulphur recovery unit and is intended for processing ammonia, while also treating the tail gases from the upstream SRU.

We look at state-of-the-art technology used in phosphate and potash mining, including equipment and systems for excavation, tailings thickening, transport, tunnelling and processing.

The refining industry, the source of half of the world’s elemental sulphur, continues to face major structural changes from changing feedstock and product slates and increasing regulatory burdens.

M. van Son and S. Sreejit of Comprimo present a case study involving the design and potential integration of the sour water and acid gas treatment units for a renewable diesel facility with an existing refinery sulphur complex. The case study evaluates the potential for operating cost reduction by integrating an enrichment loop in the acid gas treatment plant as well as for using the existing infrastructure of the refinery to limit emissions.

CRU events will convene the 2020 Phosphates International Conference & Exhibition in Paris at the Marriott Rive Gauche between 8-10 March.