Reaping the rewards of recycling

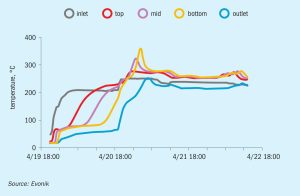

Evonik explores the development of catalyst reuse and how recycled hydroprocessing catalysts can be successfully applied in tail gas treating units to deliver cost and performance gains.

Evonik explores the development of catalyst reuse and how recycled hydroprocessing catalysts can be successfully applied in tail gas treating units to deliver cost and performance gains.

Sulphurnet discusses the importance of a whole life cycle cost analysis at the conceptual design phase when making investment decisions about new sulphur processing facilities.

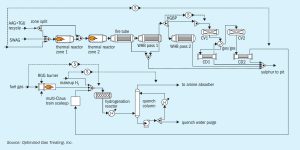

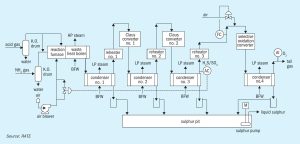

SO2 breakthroughs remain an ever present threat to the successful operation of reductive, quenchamine-based tail gas clean-up units (TGUs). Optimized Gas Treating presents a case study which demonstrates how SulphurPro's detailed reaction kinetics and mass transfer rate model can be used to analyse integration techniques and mitigation methods.

When candle filter mist eliminators installed in the absorption towers in sulphuric acid plants are not sufficiently wet, problems can occur such as free SO3 at the stack, NOx issues and emission non-compliance. Begg Cousland Envirotec discusses how these problems can be overcome by the installation of an annular wetting ring solution.

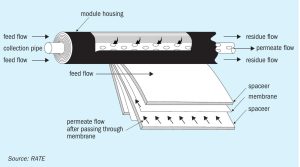

CO2 emission abatement strategies have become increasingly important as the world strives to combat global climate change. RATE discusses carbon capture options available for sulphur recovery units.

The refurbishment and modernisation of fertilizer plants offers the opportunity to reduce operating costs, raise production capacity, improve energy efficiency and cut emissions.

M. Rameshni and S. Santo of Rameshni & Associated Technology & Engineering (RATE USA) report on advanced catalysts for increasing the sulphur recovery efficiency of new and existing sulphur recovery units to meet stricter environmental regulations.

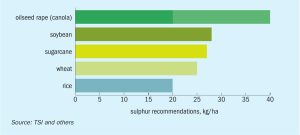

Sulphur is becoming an increasingly vital crop nutrient, due to a combination of lower sulphur deposition from the atmosphere, the increasing prevalence of high-analysis fertilizers and higher cropping intensity.

Saipem, Stamicarbon, Toyo Engineering Corporation and KBR showcase recent projects and latest technology for urea and nitric acid plants.

Stamicarbon offers advanced scrubbing technologies for fertilizer granulation plants and prilling towers. This article describes the technology and experience with the second operational MMV scrubber, which is installed at the Dakota Gasification Company’s (DGC) urea granulation plant, and highlights the successful pilot test with its JV scrubbing technology.