2025 AIChE Ammonia Safety Symposium

Venkat Pattabathula reports on the American Institute of Chemical Engineers’ (AIChE) Safety in Ammonia Plants and Related Facilities Symposium, held from September 7–11th 2025, in Atlanta, Georgia, USA.

Venkat Pattabathula reports on the American Institute of Chemical Engineers’ (AIChE) Safety in Ammonia Plants and Related Facilities Symposium, held from September 7–11th 2025, in Atlanta, Georgia, USA.

MHI has successfully completed the Ghorasal Polash Urea Fertilizer Project in Bangladesh - the country’s largest fertilizer complex. Key features of the project include: the KM CDR Process™ that captures CO2 , cuts emissions and boosts urea output; an energyefficient granulation unit using a bulk flow cooler to reduce power demand; and reinforced digital safety management.

Advances in cooling technology are providing fertilizer facilities with new options when it comes to upgrading outdated equipment and improving environmental sustainability of their existing operations. Igor Makarenko of Solex Thermal Science explores cooling strategies to improve operational efficiencies while also reducing their energy consumption, greenhouse gas emissions and overall carbon footprint.

Globally, operational renewable ammonia projects have exceeded one gigawatt (GW) of installed electrolyser capacity for the first time. Kevin Rouwenhorst of the Ammonia Energy Association (AEA) provides an overview of well-advanced projects and the associated technology options for ammonia synthesis.

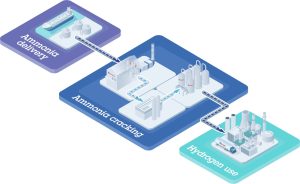

Air Liquide is developing a new ammonia cracking technology based on its proven steam methane reforming (including SMRX™ ) technology, which introduces a heat exchange concept to cut energy use, lower environmental impact, and potentially eliminate steam export. Leveraging extensive SMR design expertise, a robust R&D programme, and an industrialscale NH3 cracking pilot plant, it aims to rapidly mature all technology blocks and deliver safe, reliable, and customisable lowcarbon hydrogen solutions to meet growing demand.

Ammonia is poised to grow beyond fertilizers into energy transition roles, with lowcarbon pathways via blue ammonia and green ammonia, supported by existing logistics and market structures. To support this transition, Stamicarbon is expanding its NX STAMI™ ammonia technologies – with a mediumpressure design for large, CCUSintegrated plants and a highpressure design for small/ medium renewable projects – demonstrating efficiency, reliability, and cost advantages.

Artificial intelligence is beginning to extend into all facets of modern life, and the chemical process industry is no exception. This article looks at where and how AI is being applied in the ammonia and downstream industries, what data and infrastructure are required, and the potential risks.

Already a large urea supplier to the region, Indonesia has plans for several new plants to monetise its natural gas resources.

Blue ammonia – ammonia produced from fossil hydrogen with carbon capture and storage (CCS) – offers a cheaper alternative than green ammonia for low carbon supply in the short term, and is more suited to retrofits.

Venkat Pattabathula of SVP Chemical Plant Services, Taylor Archer of Clariant and Seshu Dharmavaram of Air Products, all AIChE Ammonia Safety Committee members, look back at some of the key lessons learned from the Symposium’s 70 year history.