Global gas markets after Ukraine

With Europe facing a long-term shortage of natural gas, and Russia looking east for new customers, how will changing global gas markets affect production of key syngas-based chemicals?

With Europe facing a long-term shortage of natural gas, and Russia looking east for new customers, how will changing global gas markets affect production of key syngas-based chemicals?

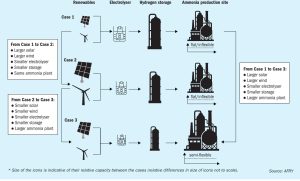

Due to the inherent nature of the renewable power, sizing eSyngas plants powered with renewable energy brings complexity normally not faced by natural gas-based facilities. In this article, Dr Raimon Marin and Dr Solomos Georgiou of AFRY discuss the application of AFRY’s state-of-the-art modelling tool to optimise the size and production of a green hydrogen system and a green ammonia plant based on given renewable power profiles and their associated variability (e.g., hourly, daily, seasonally, and annually).

Air Liquide presents the results of an internal study to identify preferred natural gas-based plant configurations at a methanol capacity of 250 t/d. Delivering small capacity plants requires a focus on the total cost of ownership (TCO) for the economics to be successful, in addition to the CO 2 footprint of the operation. As found by this study, SMR concepts are naturally power balanced for standalone greenfield operations and show no particular advantage for power import in a brownfield setting. POX and ATR cases are greatly improved and even advantaged in a brownfield setting compared to SMR when shifting from power balance to power import cases.

Advanced Methanol Amsterdam (AMA) is a production facility, that will be realised in the Port of Amsterdam's Biopark, which is destined to produce advanced methanol that meets the European renewable energy directive (RED) requirements. Once completed, AMA will be the flagship production site for GIDynamics and GIDARA Energy and for its High Temperature Winkler (HTW ® ) gasification technology. AMA will also be the first of its kind green methanol unit designed by Casale.

Casale has developed a range of methanol-ammonia coproduction processes to match different requirements according to product capacity.

The curtailment of ammonia production in Europe and reduction in export supply from Russia has led to an unprecedented year for the merchant ammonia market.

The latest improvements to melamine process technology now make it even easier to integrate a melamine plant with an ammonia and urea fertilizer complex. Guido Canti of Eurotecnica and Marc Wieschalla of thyssenkrupp Uhde discuss the benefits of plant integration.

Industry focus on technologies to reduce the carbon intensity of ammonia and methanol production has been intensifying. In this article thyssenkrupp Uhde, Proton Ventures, Toyo Engineering Corporation, Stamicarbon, BD Energy Systems and KBR report on some of their latest technology developments towards decarbonisation.

Refractories are heat resistant materials used in high temperature processes to protect industrial equipment such as utility boilers, heaters, and ammonia primary and secondary reformers against heat and chemical attack. In this article Hasan Akbari of Kermanshah petrochemical Industrial company (KPIC) reports on experiences of different stages of refractory casting in the secondary reformer of an ammonia plant, located in Kermanshah province of Iran (KPIC – Phase II). The pouring operation was carried out in three stages and each section was cast nonstop for a period of three days in total.

Fischer-Tropsch technology has long offered alternative production routes to synthetic fuels, but has struggled to make a use case outside of some niche applications. Could the greening of the chemical industry offer another way forward for the technology?