Enhancing granulation technologies

TOYO has a long history in urea granulation technologies and has recently added two new technologies to its product line-up.

TOYO has a long history in urea granulation technologies and has recently added two new technologies to its product line-up.

With the current focus on decarbonising ammonia production, Johnson Matthey explains the important role of high activity ammonia synthesis catalyst in the production of green ammonia.

Merchant markets for ammonia have faced considerable disruption in recent years due to the covid pandemic and the war in Ukraine.

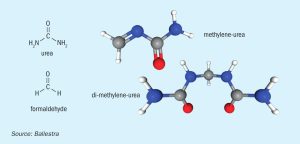

Ballestra is taking a new approach to improving nutrient use efficiency by moving methylene-urea production to the fertilizer industry. Massimo Gori and Svet Valkov of Ballestra discuss the technology and benefits of having a slow-release fertilizer that uses a product from within the fertilizer industry.

Distributed and carbon-free ammonia production with Stami Green Ammonia technology offers a highly competitive alternative to conventional grey processes, paving the way for scaling up and sustaining local communities with renewable energy sources.

Hindustan Platinum describes two recent start-up issues with catalyst gauze packs at a nitric acid plant, and their remediation to allow production to continue.

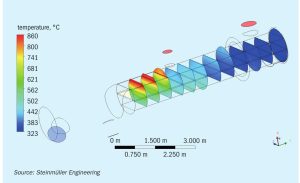

Steinmüller Engineering shares its experiences of applying CFD to re-design the waste heat boiler downstream of the secondary reformer to successfully achieve the desired uniform cross flow across the tube bundle.

With low carbon ammonia and methanol being considered not just for their chemical and fertilizer uses, but as fuels, can we make enough of them to fill our energy needs?

Low carbon production is attracting considerable attention to using syngas derivatives as fuels, but there are considerable logistical and commercial barriers to overcome.

The CO2 emissions in a hydrocarbon fed hydrogen plant occur largely during the energy intensive syngas production step. Hydrogen production is therefore a major factor in the CO2 emission balance of an ammonia plant. BASF’s OASE® technologies for CO2 capture are capable of achieving cost-effective 99.99% carbon capture at scale. In this article Elena Petriaeva and Bernhard Geis of BASF investigate different grey and blue hydrogen production technologies.