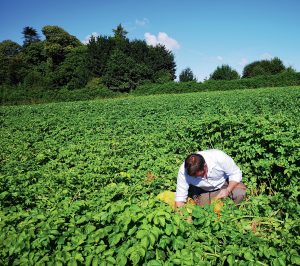

Enhanced efficiency fertilizers for sustainable agriculture

Conventional fertilizers can be transformed into enhanced efficiency fertilizers (EEFs) using coating agents and inhibitors. Greater use of EEFs, by preventing nutrient losses and avoiding excess nutrient supply, can help global agriculture become more sustainable, as Urvi Mathur of Neelam Aqua explains.