Acid demand for battery production

The switch towards battery technologies like lithium iron phosphate (LFP) is leading to major growth in demand for sulphur and sulphuric acid.

The switch towards battery technologies like lithium iron phosphate (LFP) is leading to major growth in demand for sulphur and sulphuric acid.

Madhya Bharat Agro Products has announced board approval for a major capacity expansion at its Dhule manufacturing facility. The expansion represents a comprehensive enhancement of the company's fertilizer production capabilities, including 330,000 t/a of diammonium phosphate and NPK fertilizer, a 66,000 t/a phosphoric acid plant, and a 396,000 t/a sulphuric acid plant. The expansion plan is part of a strategy of vertical integration in fertilizer production. The addition of phosphoric acid and sulphuric acid production capabilities will support the primary DAP/NPK manufacturing operations, creating operational synergies and potentially reducing input costs, according to the company.

PT QMB New Energy Materials, a major Chinese-owned nickel smelter in Indonesia, is temporarily cutting production due to mounting waste management challenges, according to a 24 November report from local news source Sina, a move expected to temporarily impact regional sulphur demand. The facility, located in the Morowali Industrial Park, will reduce output for at least two weeks as its tailings ponds are nearing capacity while it awaits approval for a new facility. The shutdown may have implications for the sulphur market, as QMB is a major consumer.

Süd-Chemie discusses the importance of pressure drop in a sulphuric acid plant and the many benefits that can be gained from using a guard bed, typically in the first bed of the converter to safeguard the catalyst bed and increase campaign life.

Thiomaterials reports on the key features and successful performance of Thiotrack sulphur concrete sleepers, offering high fatigue endurance with a truly reversible circular binder.

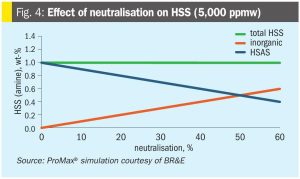

Bryan Research & Engineering (BR&E) and INEOS GAS/SPEC continue their review of neutralisation of heat stable salts. Part 2 focuses on how caustic (NaOH) affects amine chemistry and corrosion and the effects of adding too much NaOH.

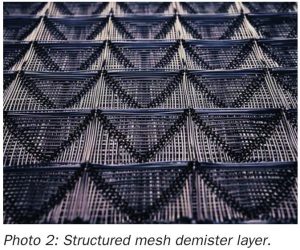

Begg Cousland Envirotec reviews different mist eliminator types and some of the operational problems encountered which can be managed by correct installation, targeted cleaning or replacement, and selecting appropriate corrosion-resistant materials.

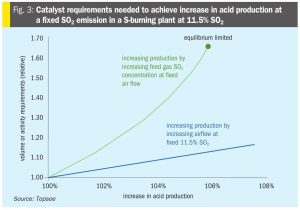

In this real world case study, Topsoe demonstrates how cost effective catalyst changes can result in significant production increase without any equipment changes or revamps, all while maintaining compliance with emission limits.

Recalibrate™ has developed a next generation sulphur burning plant to produce sulphuric acid with ultra-low sulphur dioxide and zero NOx emissions, designed to derisk the permitting process and increase speed to market for new sulphuric acid plants.

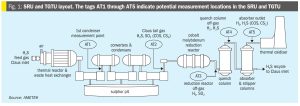

Maximising sulphur recovery in a modified Claus SRU/TGTU requires controlling and monitoring COS and CS2. Leveraging decades of monitoring experience, AMETEK Process Instruments discusses the formation, impact and monitoring of COS and CS2.