One size does not fit all

K. Hanlon Kinsberg and J. Lewis of Comprimo review the main approaches for mercaptan removal in gas processing plants, based on past project experience and generally accepted industry practice.

K. Hanlon Kinsberg and J. Lewis of Comprimo review the main approaches for mercaptan removal in gas processing plants, based on past project experience and generally accepted industry practice.

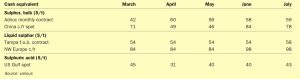

The risk of a second Covid-19 wave over the winter period continues to fuel the trend of forward trading of sulphur cargoes. Downward pressure in some sectors for demand is likely as the macro economic forecast remains challenging.

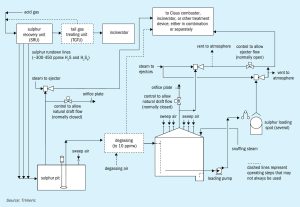

Undegassed molten sulphur can contain several hundred ppmw H2 S. If the headspace in the storage tank is stagnant, the H2 S can accumulate in the vapour space above undegassed liquid sulphur to dangerous levels. Sweeping and blanketing systems are commonly applied to manage the explosion risk in the headspace of molten sulphur storage tanks. D. J. Sachde , C. M. Beitler , K. E. McIntush , and K. S. Fisher of Trimeric Corporation review these approaches, outlining the benefits and limitations, design considerations, and industry experience/guidance for each approach. Calculation methods for natural draft flow of sweep air are also presented.

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Chris Heaton has joined Baker Engineering and Risk Consultants, Inc. as Chief Executive Officer. Chris replaces Quentin Baker as part of BakerRisk’s ownership and management succession plan. Baker will remain with BakerRisk, serving as chairman of the board, and will continue to support clients with incident investigations, engineering studies and research programs. Heaton has executive experience with risk engineering and consulting, fire protection engineering, life safety and incident investigation companies, and holds degrees in civil engineering and architecture.

In a few short years Abu Dhabi has grown to become the world’s largest sulphur producer and exporter, and new sour gas projects will lead to additional sulphur recovery capacity, provided they can overcome economic challenges.

For the protection of nozzles in sulphur forming plants it is important to prevent larger particles from entering the forming machinery and possibly blocking the nozzles. In normal operation, pipeline strainers are used. Sulphurnet has designed a new system which is suitable for continuous or batch operations and has lower maintenance costs. J. Hermans of Sulphurnet introduces the self-cleaning sulphur strainer.

Reg Adams of pigments and titanium dioxide consultancy Artikol reviews the demand for sulphuric acid in the manufacture of TiO2 , and the prospects for consumption over the next few years.

Haldor Topsoe and Comprimo® have announced a global strategic alliance to jointly license the TopClaus sulphur removal and recovery technology. TopClaus combines Topsoe’s energy efficient wet sulphuric acid (WSA) process with the industry-standard Claus process, enabling plant operators to handle acid gases and achieve sulphur removal efficiencies of above 99.9%. The Claus part of the unit recovers elemental sulphur from acid gases, and the tail gases from the Claus unit are then treated in the WSA unit, where the remaining sulphur compounds are converted into sulphuric acid.