Status of renewable ammonia projects and technology licensors

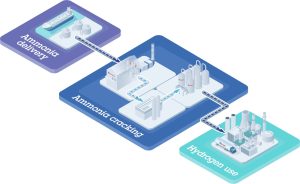

Globally, operational renewable ammonia projects have exceeded one gigawatt (GW) of installed electrolyser capacity for the first time. Kevin Rouwenhorst of the Ammonia Energy Association (AEA) provides an overview of well-advanced projects and the associated technology options for ammonia synthesis.