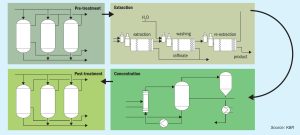

KBR’s proprietary phosphoric acid purification technology

KBR designs and builds customised phosphoric acid purification plants tailored to the individual demands of clients. Christopher Heikkilä, KBR’s Business Development Manager, outlines the process design requirements and the challenges associated with impurities removal.