Sulphur 420 Sep-Oct 2025

15 September 2025

A small component with a big impact

SULPHURIC ACID EQUIPMENT

A small component with a big impact

CS Combustion Solutions introduces the SR-P sulphur atomiser nozzle to the sulphuric acid process, combining the high-quality atomisation of ultrasonic systems with the affordability and simplicity of pressure atomisers.

Sulphuric acid remains one of the most important chemicals worldwide, essential for the production of fertilizers, chemicals, and numerous industrial applications. The efficiency and reliability of sulphur combustion are essential for economics and sustainability of acid production plants. Among the various components in this complex process, one element often appears deceptively small yet has a disproportionate impact on overall plant performance: the sulphur atomiser nozzle. A clean and precise atomisation of molten sulphur is crucial for complete combustion, reliable operation and the protection of refractory linings. In short, nozzle performance defines plant performance.

CS Combustion Solutions is challenging itself to continuously develop and introduce new technologies. The latest in a line of nozzles for the sulphur industry is the introduction of its SR-P nozzle, a breakthrough technology that combines the atomisation quality of ultrasonic systems with the cost efficiency of pressure atomisers. Designed to minimise operating and maintenance requirements while ensuring superior combustion performance, the SR-P is set to redefine sulphur burning in modern acid plants.

The challenge of sulphur atomisation

Atomising molten sulphur for combustion presents multiple challenges. The droplet size must be small enough to ensure rapid conversion from sulphur to SO2, yet large droplets often survive too long in the furnace, hitting refractory surfaces and causing hot spots or damage. An uneven spray pattern may result in localised overheating, inefficient combustion, and premature wear of expensive lining materials.

Traditional technologies have their respective strengths and weaknesses. Rotary-cup atomisers, while capable of producing fine droplets, involve rotating components in high-temperature environments, which makes them maintenance-intensive and energy-demanding. Pressure atomisers, by contrast, are simple and relatively cost-efficient, but they tend to produce coarser droplets, are prone to clogging, and require frequent replacement of nozzles and tips. Ultrasonic atomisers offer excellent spray quality, but they come at higher investment costs and can be perceived as less economical in smaller-scale or budget-sensitive operations.

Operators are therefore confronted with a trade-off: high efficiency but high cost, or cost-efficiency with compromises in spray quality.

The new solution: SR-P nozzle

The SR-P nozzle was developed to close this gap. It represents a new generation of atomisation technology, combining the high-quality atomisation of ultrasonic systems with the affordability and simplicity of pressure atomisers. This hybrid approach ensures operators no longer need to choose between efficiency and cost.

The SR-P achieves a droplet size of approximately 150 μm, which is fine enough to ensure complete sulphur combustion. This reduces the thermal stress on the furnace refractory linings and improves lifetime. The nozzle supports a broad operating range from 20% to 110% load, offering unmatched flexibility for plants that must adapt to variable production demands. Additionally, the spray pattern is adjustable, allowing operators to optimise the flame geometry for different furnace designs or process conditions.

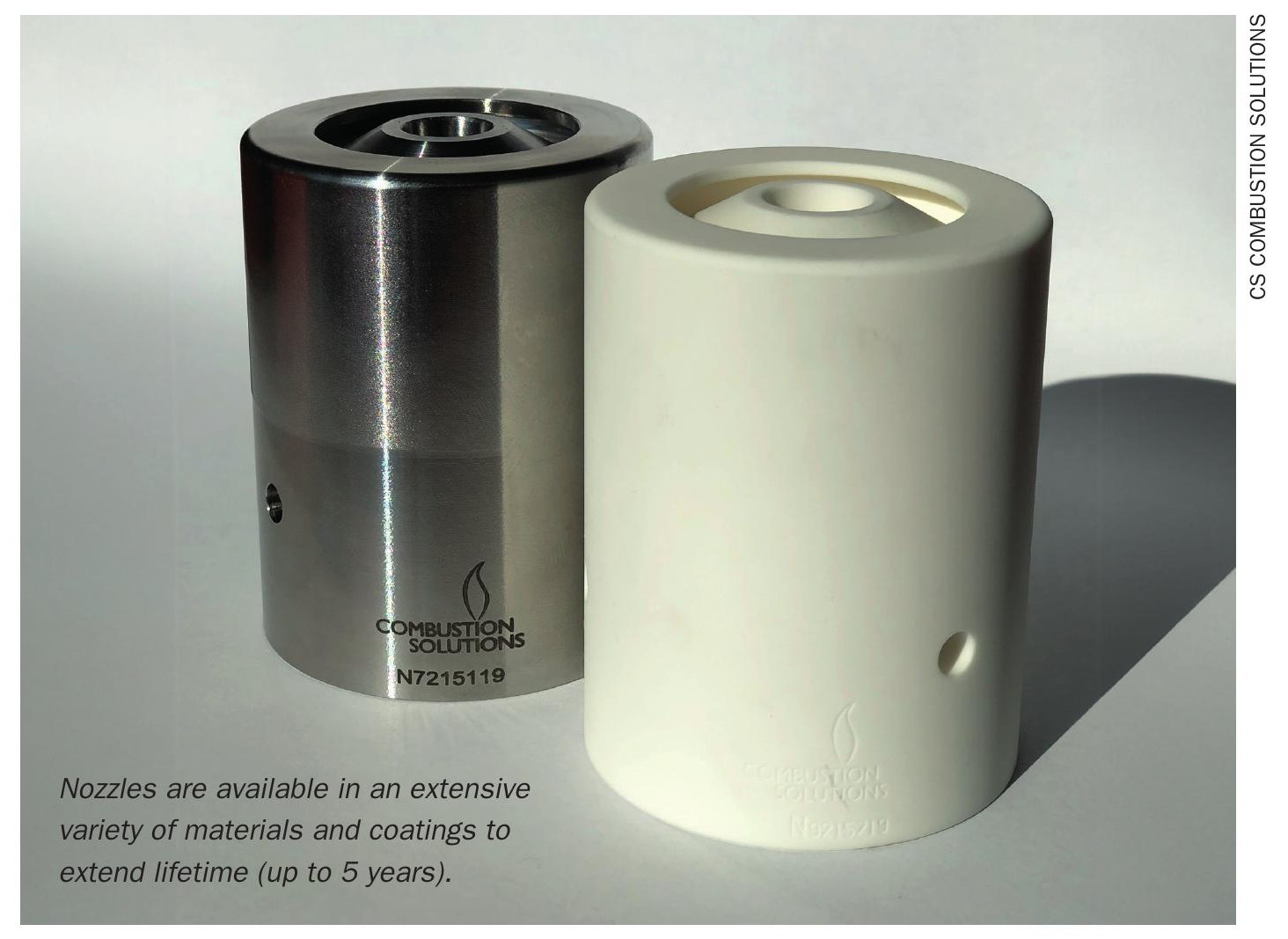

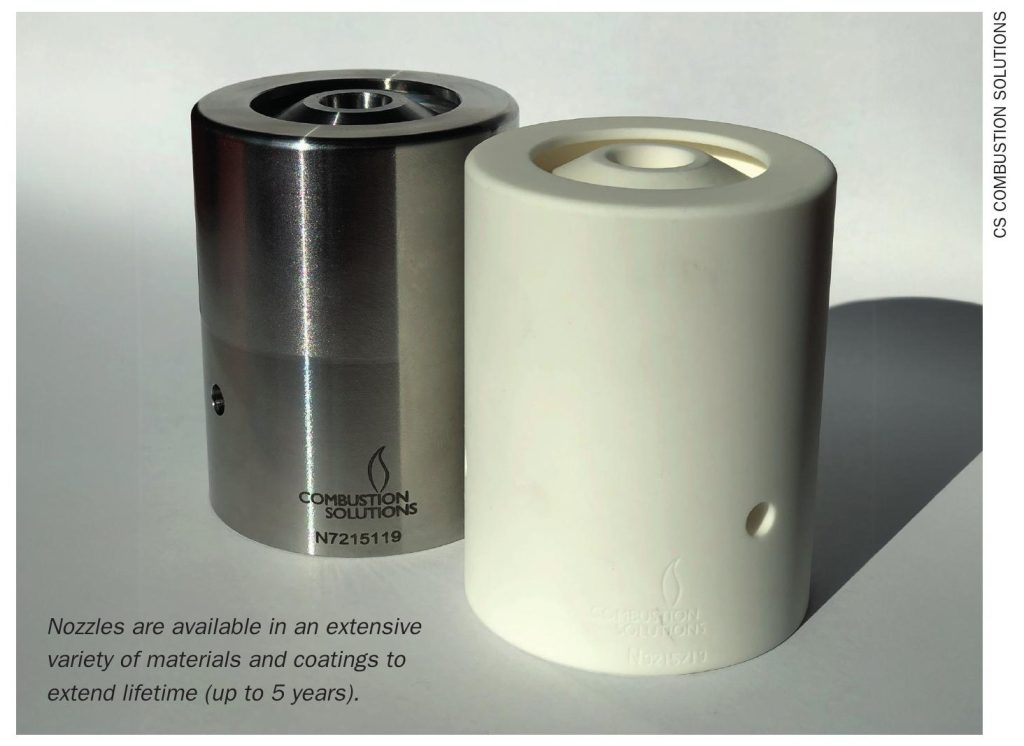

To further enhance operational reliability, the SR-P is available in a wide range of materials, including stainless steel, high-performance alloys, ceramics, and even tantalum-coated designs for particularly aggressive operating environments. This material flexibility ensures durability and compatibility across different process conditions and plant designs.

Technical and economic advantages

One of the defining advantages of the SR-Pnozzle is its minimal maintenance requirement. Without moving parts or highly sensitive geometries, the risk of clogging and wear is significantly reduced. Operators benefit from longer service intervals and lower spare part consumption, directly reducing operating costs.

Because of the fine and uniform atomisation, the thermal load on the refractory is minimised. Fewer hot spots mean less damage and longer service life of expensive lining materials, further reducing lifecycle costs. At the same time, the rapid sulphur-to-SO2 conversion enabled by the SR-P allows plants to increase capacity without requiring modifications to the furnace. This is a decisive advantage for operators looking to expand production without the need for costly and time-consuming revamps.

Energy demand is also optimised. With no need for rotating motors, as in rotary-cup systems, the SR-P keeps auxiliary power consumption low, aligning with current efforts to improve energy efficiency in sulphuric acid production.

Taken together, these benefits mean that the SR-P nozzle delivers a compelling return on investment: low acquisition cost, minimal maintenance, reduced downtime, extended refractory lifetime, and increased production capacity.

Application areas

The SR-P nozzle is designed for versatility. Its primary application is in sulphuric acid production, where the reliability and efficiency of sulphur combustion directly determine plant performance. But its benefits extend to other critical areas of chemical and environmental engineering.

In spent acid applications, where the combustion of sulphur-bearing residuals presents particular challenges, the SR-P ensures stable atomisation and reliable performance under varying feed conditions. Its robust materials and clog-resistant design make it ideal for this demanding environment.

The SR-P is also suitable for wastewater treatment processes, where clean atomisation of large amounts of contaminated water is a challenge. Here, too, its ability to combine fine atomisation with low maintenance offers plant operators peace of mind and operational reliability.

What It means for operators

For operators of sulphuric acid plants and related facilities, the SR-P nozzle represents more than just an incremental improvement. It is a transformational upgrade that addresses the key concerns of modern production: reliability, cost control, flexibility, and capacity expansion. Operators will benefit from:

• Lower operating costs thanks to reduced spare part consumption and minimal maintenance.

• Extended refractory life, reducing both planned and unplanned shutdowns.

• Higher flexibility, with a turndown range of 20–110% to match varying load requirements.

• Increased capacity without major furnace modifications, thanks to rapid sulphur-to-SO2 conversion.

• Improved sustainability, with lower energy consumption and reduced material wear per ton of acid produced.

Ultimately, the SR-P nozzle allows operators to achieve higher productivity with lower risk and lower cost.

Outlook

The future of sulphur combustion is increasingly shaped by the twin goals of sustainability and cost optimisation. As the fertilizer, chemical, and metallurgical industries face growing pressure to reduce emissions, cut energy use, and operate more efficiently, innovative technologies like the SR-P nozzle will play a decisive role.

By combining the strengths of ultrasonic and pressure atomisation technologies, CS Combustion Solutions has created a product that delivers high atomisation quality without compromising on economy. The SR-P demonstrates that even the smallest component of a complex process can deliver the largest impact when designed with precision and innovation.

For plant operators, adopting the SR-P nozzle is more than an equipment choice – it is a strategic decision to secure long-term competitiveness, sustainability, and reliability in sulphuric acid production.