Fertilizer International 528 Sep-Oct 2025

13 September 2025

Valorisation of fluorosilicic acid from phosphoric acid: a sustainable approach

AFA TECHNICAL CONFERENCE

Valorisation of fluorosilicic acid from phosphoric acid: a sustainable approach

In this article by Marc Sonveaux, Prayon’s innovative approach to fluorosilicic acid (FSA) valorisation is explored, with a focus on its transformation into dicalcium phosphate (DCP) through a hydrochloric acid based process that combines FSA with sodium chloride and sulphuric acid.

Introduction

The fluorine naturally present in phosphate rock is partially released during phosphoric acid production. These fluorine emissions need to be properly managed. In modern phosphoric acid plants, fluoride reacts with silicates to form fluorosilicic acid (FSA) which can be captured using dedicated scrubbing systems.

Traditionally, the resulting FSA is typically regarded as a waste stream that usually needs to be neutralised or discarded – a viewpoint that is, however, increasingly outdated. Instead, with a growing emphasis on sustainability and the circular economy, industries are reevaluating by-products like FSA as potential resources instead.

This paper explores Prayon’s innovative and circular approach to FSA valorisation, focusing on its transformation into dicalcium phosphate (DCP) through a process that combines FSA with sodium chloride and sulphuric acid.

FSA recovery in the phosphoric acid process

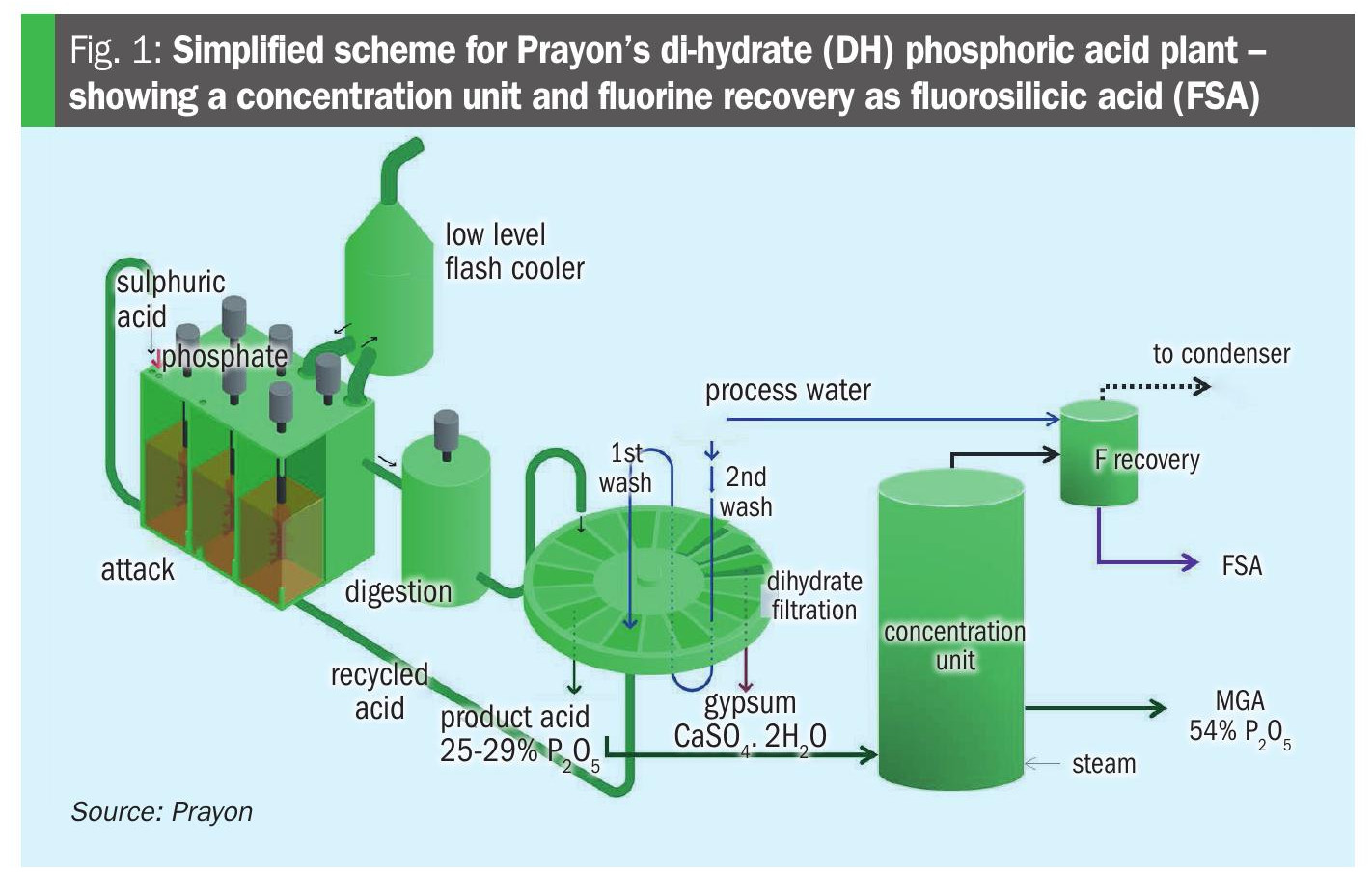

In the di-hydrate (DH) phosphoric acid process, the amounts of fluorine released during the initial reaction stage, which operates at low temperature and low acid concentration (26-28% P2O5), are too limited to be economically useful – and are therefore recovered in a gas scrubber to meet emissions regulations.

Instead, the majority of fluorine emissions occur during the concentration stage, being released primarily as silicon tetrafluoride (SiF4) and hydrogen fluoride (HF). These gases are absorbed in water within fluorine recovery units, such as those designed by Prayon Technologies, forming an aqueous solution of fluorosilicic acid (H2SiF6), typically at 18-22% concentration (Figure 1).

Quantitatively, for every tonne of P2O5 produced, approximately 0.1 tonnes of FSA solution are generated. In a typical phosphoric acid plant producing 250,000 tons of P2O5 annually, this equates to roughly 17,000 tonnes of 100% FSA.

Rethinking FSA: from waste to value

There are several ways to remove FSA to ensure it is treated responsibly and complies with regulations.

FSA can also be neutralised with limestone or other chemicals, forming calcium fluorosilicate, which is stacked with phosphogypsum. While safer, this method incurs operational costs and requires investment in water treatment infrastructure.

FSA is also used to produce specialty fluoride products like sodium fluoride or aluminium fluoride. It can also be converted to sodium, magnesium or potassium fluorosilicates. The viability of these products does, however, depend on market demand, purity requirements, and production capacity.

But, by staying within the phosphate industry, FSA can also provide a commercially useful source of protons (acid). Valuably, this acidity can be harnessed to produce phosphate products. For example, FSA can produce dilute phosphoric acid if reacted with phosphate rock. Then, if the resulting filtrate is neutralised, di-calcium phosphate (DCP) can be produced. While such processes exist, they face challenges due to their poor filterability (linked to the presence of silicates forming gels), the high fluorine content of final products, and limited scalability.

Prayon’s alternative: the HCl-based DCP process

To overcome these challenges, Prayon has developed a novel process using FSA as an acid source, supplemented with sodium chloride and sulphuric acid (for hydrochloric acid regeneration), to produce high-quality DCP from low-grade phosphate rock, such as beneficiation tailings. An overview of this HCl-based DCP process is provided below.

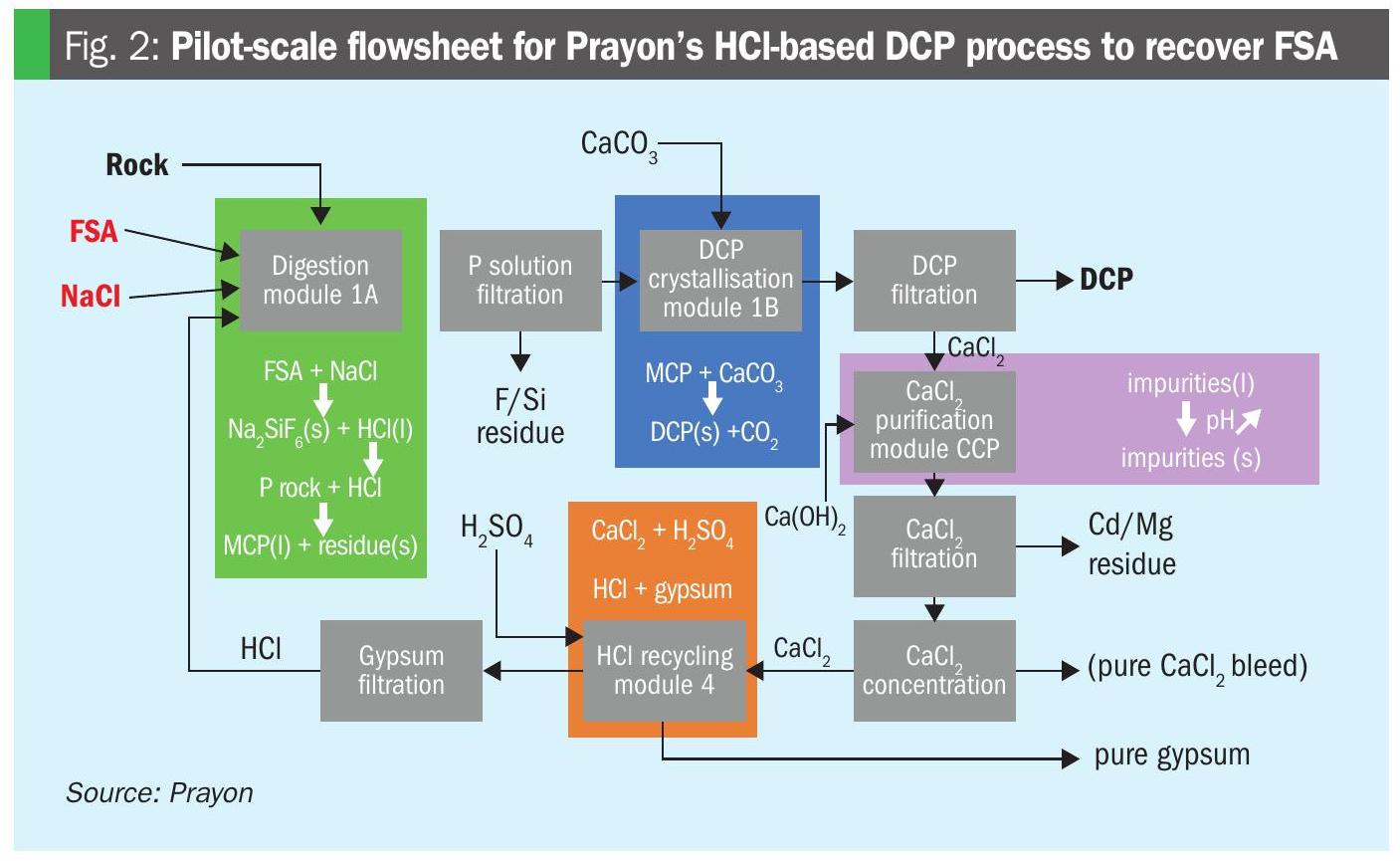

Phosphate rocks containing 20-30% P2O5 were evaluated at pilot scale using the flowsheet shown in Figure 2.

The process consists of several integrated stages:

Digestion: Phosphate rock is digested using a mixture of FSA, sodium chloride (NaCl) and recycled hydrochloric acid (HCl). During this reaction:

• Fluorine is removed as sodium fluorosilicate and calcium fluorosilicate.

• Insoluble materials such as silicates (sand), aluminium and iron are separated as filter cake.

• Approximately 75-95% of the fluorine and silicon introduced via FSA are removed in this stage.

Neutralisation: The filtrate resulting from digestion contains phosphate (in the form of monocalcium phosphate) and calcium chloride, along with dissolved magnesium and cadmium. Neutralisation with a calcium source (e.g., limestone) precipitates dicalcium phosphate (DCP) which is then dried. Depending on process parameters, the DCP can meet the quality specifications for animal feed applications.

HCl regeneration: To maintain process continuity and increase capacity, hydrochloric acid is regenerated from the calcium chloride stream as follows:

• The stream is purified via limestone neutralisation, removing cadmium and magnesium as solid residues.

• After optional bleeding, the purified calcium chloride solution is concentrated to balance water content.

• Reaction with sulphuric acid produces high-purity gypsum (≥99%, snow-white) and regenerates HCl – which is then recycled to the digestion stage.

Pilot-scale validation of the process was conducted at Technophos, Prayon’s R&D facility in Bulgaria. This semi-industrial plant provides a processing capacity of up to 500 kg/h. Various phosphate rocks with P2O5 contents ranging from 20–30% were tested using the flowsheet in Figure 2.

The pilot-scale validation has shown the new HCl-based DCP process is feasible, with the following key outcome:

• Process stability: Smooth operation with consistent yields.

• Efficiency: Overall P2O5 yield between 75-80%.

• Filterability: Data collected confirmed feasibility for industrial scale-up.

• Product quality: DCP produced was of fertilizer quality or met animal feed standards, depending on the parameters used.

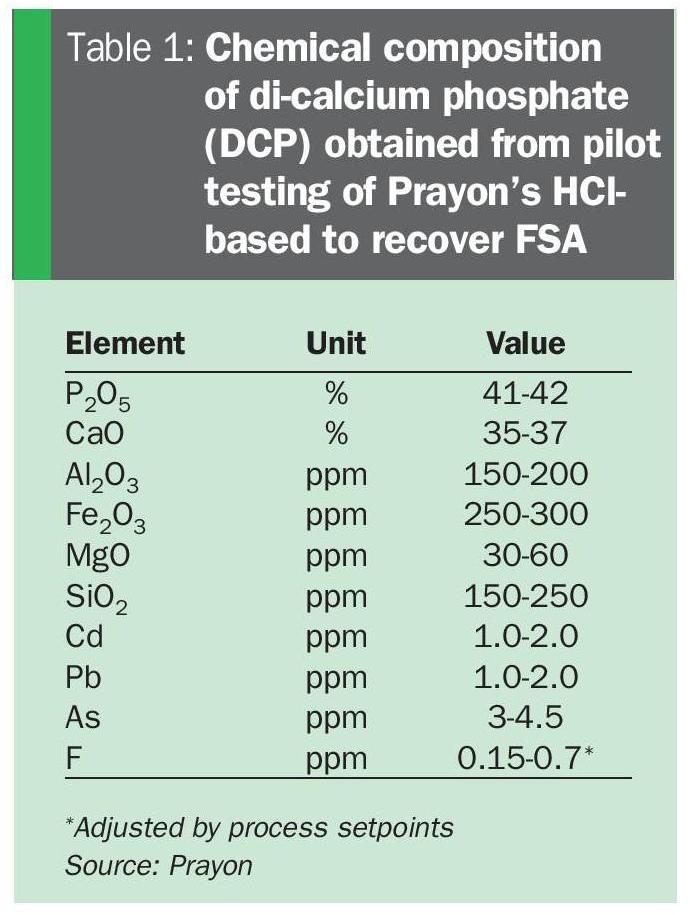

The chemical composition of the DCP obtained is shown in Table 1.

Industrial Integration and market potential

Integration of the DCP process into existing phosphoric acid plants offers multiple benefits:

• FSA utilisation: A plant producing 250,000 tonnes per year (kt/year) of P2O5 generates ~17 kt/year of FSA as 100%, which can be fully recovered and valorised.

• DCP production: With this FSA quantity, approximately 70 kt/year of DCP can be produced (28 kt/year P2O5), suitable for animal feed or used to produce high quality phosphoric acid or fertilizers.

• Gypsum output: ~110 kt/year of high-purity gypsum is generated, marketable for plaster, plasterboard, cement or even applications that need a very white and clean gypsum.

• Residue management: Digestion residues can be co-managed with phosphogypsum, simplifying waste handling.

Environmental and economic implications

As well as valorising co-products, integration of this process can also diversify the product portfolios of phosphoric acid producers. The proposed process also helps deliver key sustainability goals:

• Waste minimisation: Converts a hazardous by-product into valuable materials.

• Resource efficiency: Utilises low-grade phosphate rock, reducing reliance on high-grade reserves.

• Circular economy: Regenerates reagents and recycles process streams.

• Market diversification: Opens access to animal feed, construction, and specialty chemical markets.

Economically, the process reduces disposal costs, creates revenue streams from DCP and gypsum, and enhances plant capacity through reagent recycling.

Conclusion

In the evolving landscape of industrial sustainability, the treatment and valorisation of by-products are becoming central to strategic decision-making. One such by-product, fluorosilicic acid (FSA), is often neutralised and disposed of – an approach that not only incurs cost but also destroys potential value.

Instead of treating it as a waste stream, the valorisation of FSA through Prayon’s HCl-based DCP process offers a sustainable, economically viable alternative. This approach not only recovers valuable acidity but also enables the production of high-quality products from low-grade phosphate rock.

It is important to recognise that not all phosphate rocks are equal. Each deposit has unique characteristics that influence its behaviour during processing. Full validation of each rock type is therefore essential to optimise recovery and ensure consistent product quality.

Prayon Technologies is well placed to support this validation thanks to its comprehensive technical capabilities and infrastructure. These include the company’s specialised engineering teams, and its advanced research, pilot and semi-industrial facilities in Belgium and at Technophos in Bulgaria.

Acknowledgement

Marc Sonveaux, Prayon’s Head of Industrialization, will be presenting this article at the 37th AFA International Technical Conference & Exhibition, Ben Guerir, Morocco, 17th September 2025.